Welding machine and welding method

a welding method and welding machine technology, applied in the direction of machines/engines, mechanical equipment, manufacturing tools, etc., can solve the problems of degrading sealing performance and welding failure, and achieve the effect of reducing the fuel leakage of the injector

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The following description of the preferred embodiments is merely exemplary in nature and is in no way intended to limit the invention, its application, or uses.

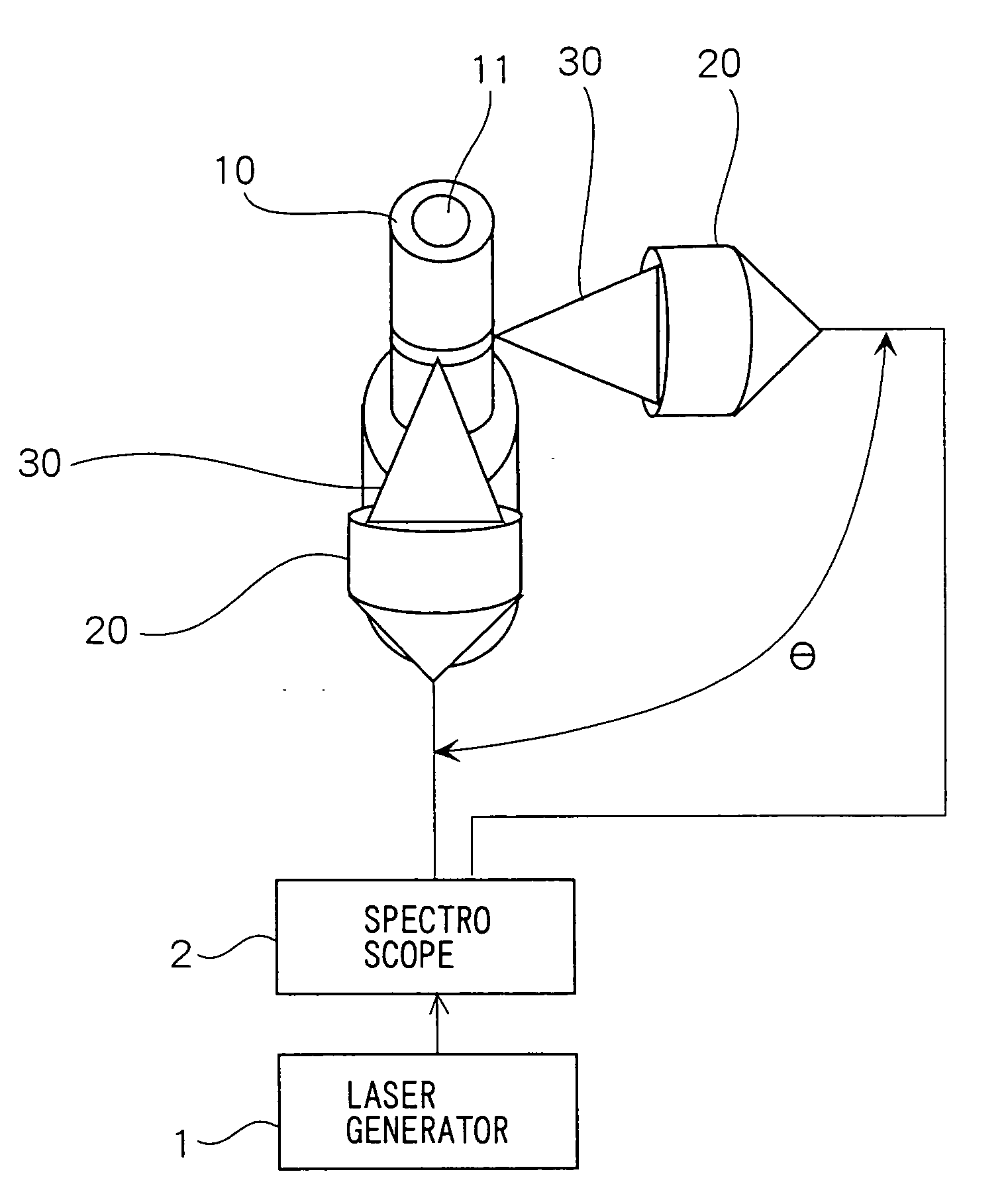

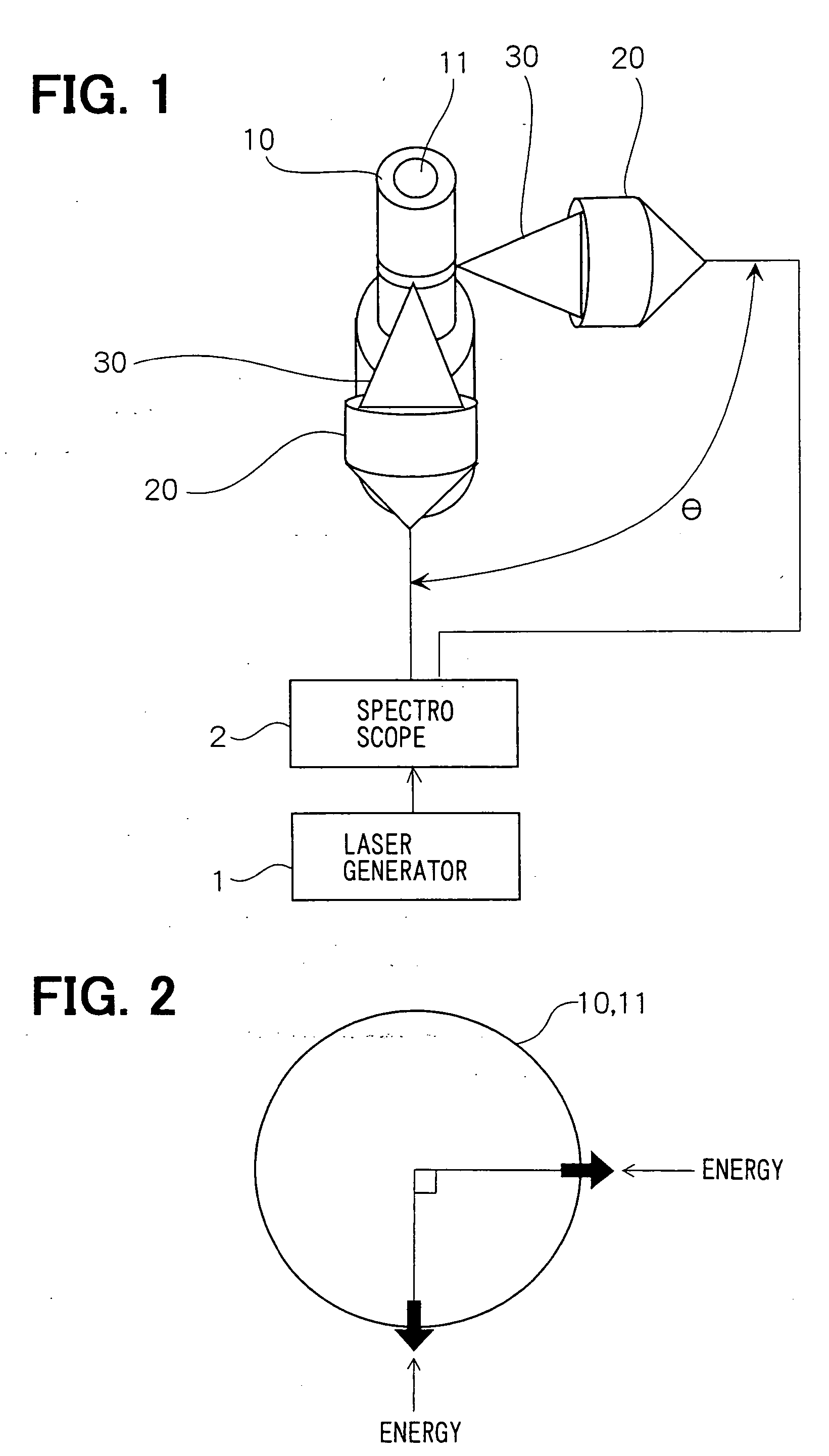

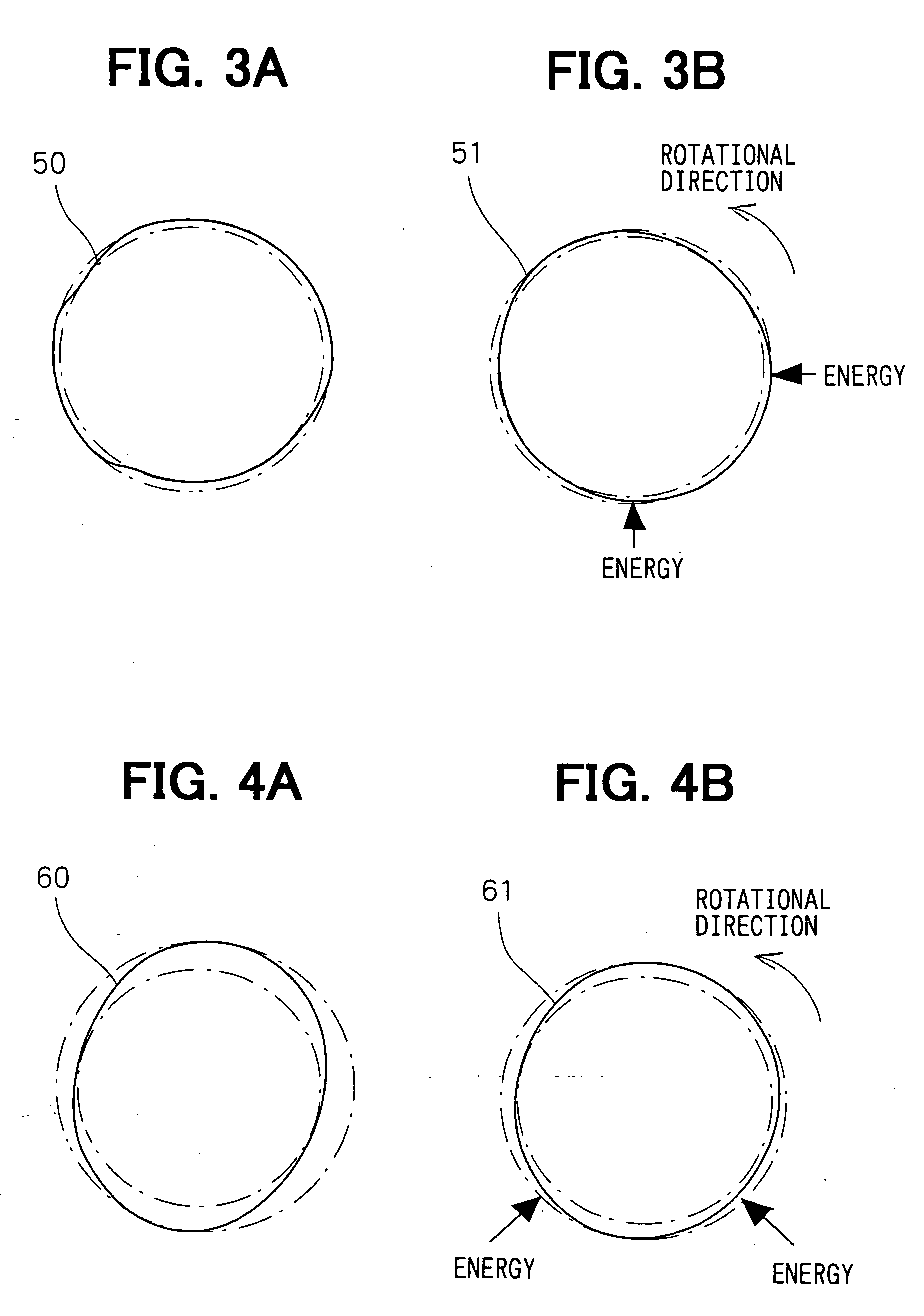

[0040]FIG. 1 is a schematic view showing a welding machine in an embodiment of the present invention. An outer cylinder member 10 and an inner cylinder member 11 have circular cross-sections, and the inner cylinder member 11 is press-fitted into the outer cylinder member 10. For example, the outer and inner cylinder members 10, 11 could be a combination of a housing of an injector and a nozzle body, respectively.

[0041] A laser generator 1 as an energy source generates a high-energy laser beam such as an yttrium aluminum garnet (YAG) laser beam and a carbon oxide (CO2) laser beam. A laser beam, generated by the laser generator 1, is dispersed in two directions by a spectroscope 2. Two dispersed laser beams are focused on the outer cylinder member 10 by two optical heads 20 as energy-applying units, respectively. The o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com