Regeneration method of waste concrete and modified recycled concrete

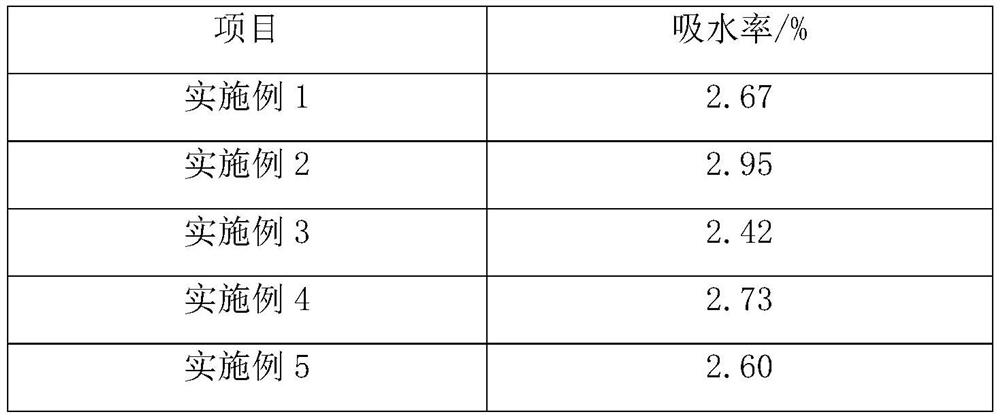

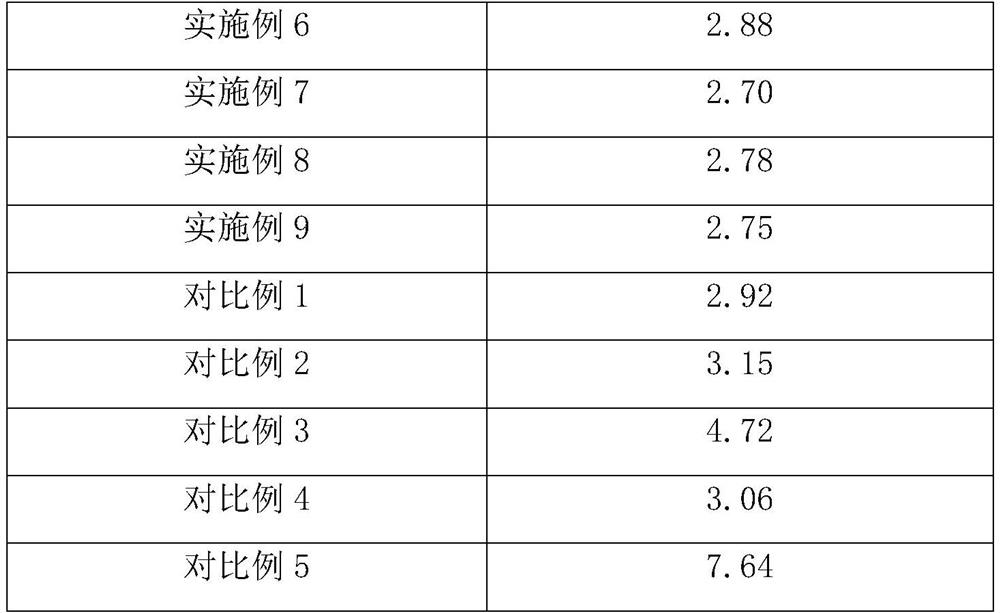

A technology for waste concrete and recycled concrete, applied in the field of concrete, can solve the problems of low concrete strength, high water absorption rate of recycled aggregates, large shrinkage, etc., and achieve the effects of improving strength, improving mechanical strength and impermeability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0041] Preparation example 1: Water-based acrylic resin liquid is prepared by the following method:

[0042] Weigh 1 kg of liquid water-based acrylic resin, 0.3 kg of silane coupling agent KH-570, and 2 kg of water, mix them, and then stir at a speed of 500 r / min for 15 minutes to prepare a water-based acrylic resin liquid.

preparation example 2

[0043] Preparation example 2: Water-based acrylic resin liquid is prepared by the following method:

[0044] Weigh 1 kg of liquid water-based acrylic resin, 0.25 kg of silane coupling agent KH-570, and 2 kg of water, mix them, and then stir at a speed of 500 r / min for 15 minutes to prepare a water-based acrylic resin liquid.

preparation example 3

[0045] Preparation Example 3: Water-based acrylic resin liquid is prepared by the following method:

[0046] Weigh 1 kg of liquid water-based acrylic resin, 0.5 kg of silane coupling agent KH-570, and 2 kg of water, mix them, and then stir at a speed of 500 r / min for 15 minutes to prepare a water-based acrylic resin liquid.

[0047] Preparation example of composite fiber

[0048] The alkaline silica sol in the following raw materials was purchased from Jinan Yingchu Chemical Technology Co., Ltd.; the polyacrylonitrile fiber was purchased from Shandong Jinrun Engineering Materials Co., Ltd., with a length of 5mm; the spiral polyvinyl alcohol fiber was purchased from Hebei Qicheng Road and Bridge Maintenance Engineering Co., Ltd. , length 3mm; other raw materials and equipment are commercially available.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com