Processing process of environment-friendly sound insulation pad

A processing technology and sound-insulating pad technology, applied in the direction of adhesive additives, filament/wire forming, non-polymer adhesive additives, etc., can solve the problems of reducing the mechanical strength of fibers, reducing the density, and reducing the sound absorption effect. Achieve the effect of improving sound absorption capacity, reducing fiber density and maintaining mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

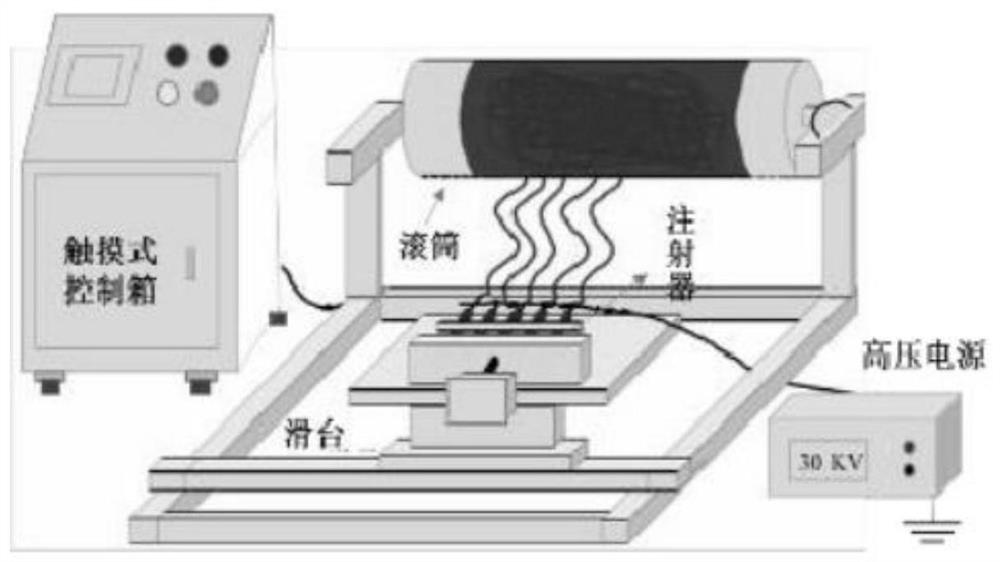

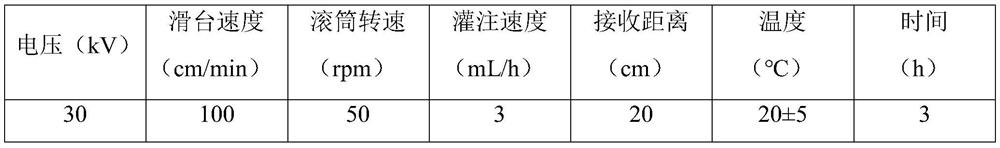

[0020] Embodiment 1: The electrospinning device used in the present invention is mainly composed of a high-voltage power supply (the voltage adjustment range is 0-30kV, and the micro-injection pump can be equipped with 10 nozzles. The diameter of the syringe needle used in this embodiment is 0.4mm, and the drum receiving device (The speed adjustment range is 0-200r / min, the length of the roller is 60cm and the reciprocating sliding table device (moving speed range is 0-20°Cm / min), the device such as figure 1 shown.

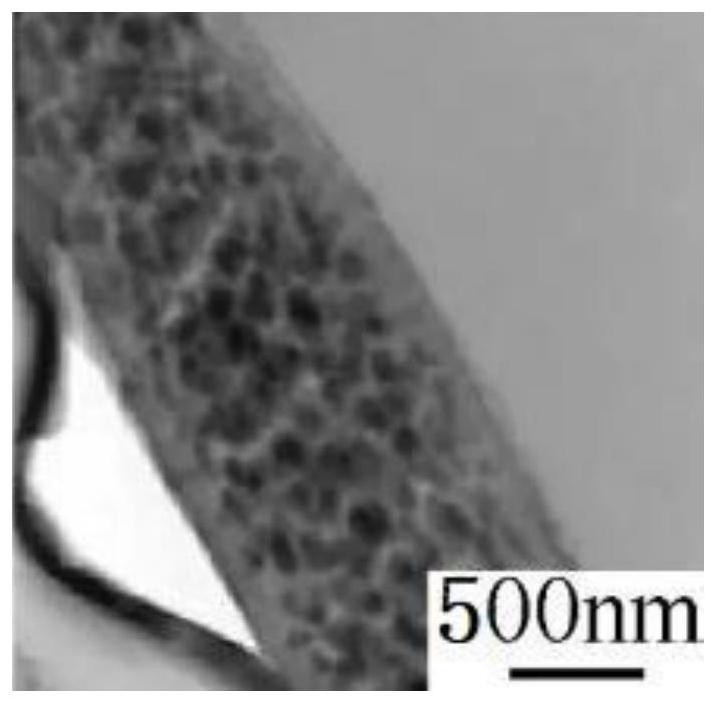

[0021] The present invention selects polyacrylonitrile (PAN) or polyethylene terephthalate (PET), which has a relatively mature electrospinning process, as solute and DMF as solvent spinning to prepare polyester fibers, so as to obtain PET nanofibers with good morphology. Membrane or mesoporous fiber membrane, so as to obtain nanofiber material with better sound absorption performance. The specific steps are:

[0022] (1) Preparation of PET nanofiber membranes u...

Embodiment 2

[0044] Embodiment 2: all the other are identical with embodiment 1, difference is:

[0045] The ambient humidity in the step (1) is set to 50 ± 5%;

[0046] With the amount of mesoporous material added as 0.05, 0.1, 0.2, 0.4, 0.8 and 1.0wt% of the polyacrylonitrile spinning solution, set up experimental groups to prepare mesoporous fiber membranes respectively, and measure the mechanical strength of mesoporous fiber membranes. The results are as follows :

[0047] Table 5 Effect of mesoporous materials on sound absorption coefficient and mechanical strength of mesoporous fiber membranes

[0048]

[0049] The results in Table 5 show that the addition of mesoporous materials will make the interior of the PAN fiber porous. With the increase of the amount of mesoporous materials, the PAN fibers become more fluffy, resulting in a gradual decrease in the mechanical strength of the mesoporous fiber membrane, but the absorption The sound coefficient gradually increases. In order ...

Embodiment 3

[0050] Embodiment 3: all the other are identical with embodiment 1, difference is that SiO 2 The airgel accounts for 0, 0.1, 0.2, 0.3, 0.4, 0.5, 0.6, 0.7, 1.0% of the total weight of the colloid, and the humidity is set at 50±5%. The sound absorption coefficient of the composite membrane was measured, and the results are as follows:

[0051] Table 6 Effect of airgel in colloid on sound absorption coefficient

[0052]

[0053]

[0054] The results in Table 6 show that although the addition of airgel can significantly improve the sound absorption coefficient of the composite membrane, due to the extremely small specific gravity of aerogel, adding too much airgel will lead to a decrease in the adhesion between the membrane layers, and There is limited help in improving the noise reduction coefficient.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

| Areal density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com