Manufacturing method of substrate and manufacturing method of wiring substrate

A manufacturing method and substrate technology, which are applied in the field of substrate manufacturing and wiring substrate manufacturing, can solve problems such as metal ion concentration deviation, and achieve the effects of high connection reliability, avoiding deviation of metal filling degree, and improving productivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach )

[0059]

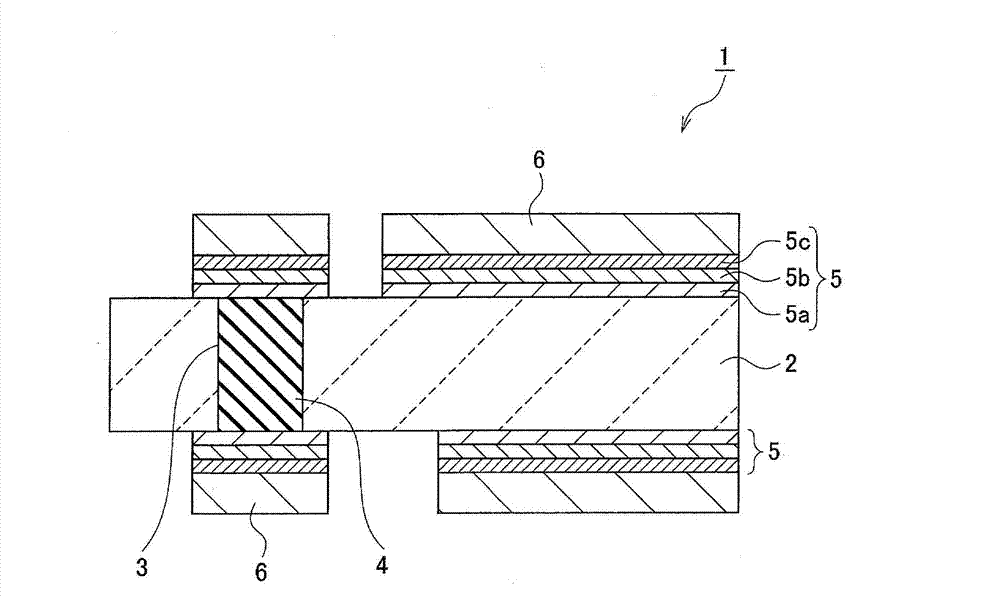

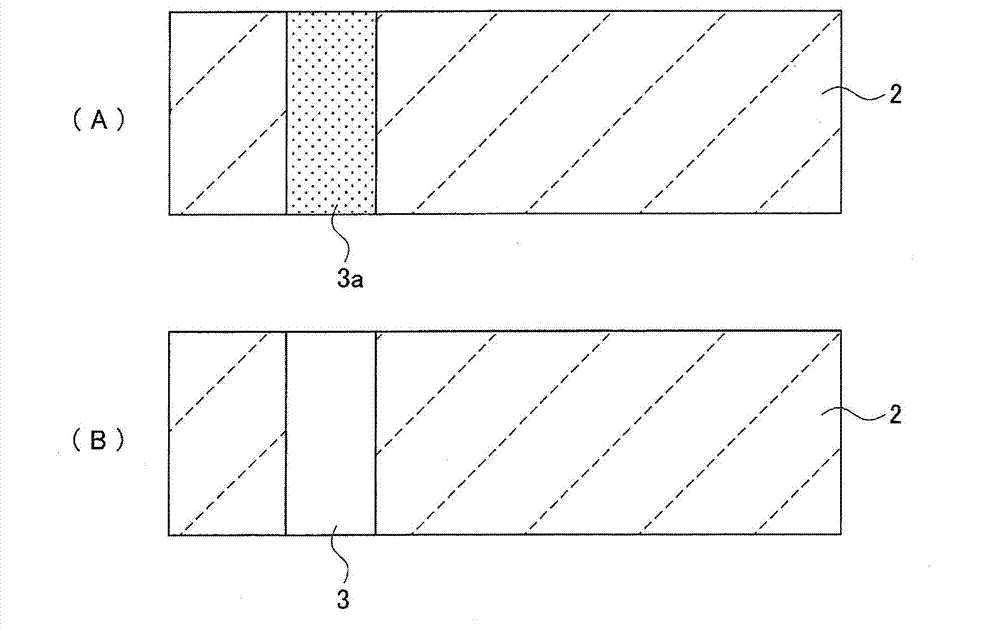

[0060] figure 1 It is a cross-sectional view showing a configuration example of the wiring board according to the embodiment of the present invention. The illustrated wiring board 1 is configured using a glass substrate 2 . The glass substrate 2 is used as a core substrate of the wiring substrate 1 . The glass substrate 2 is provided with multiple ( figure 1 Only 1 shown in ) through hole 3. Through hole 3 is filled with metal 4 . Wiring patterns 6 are formed on the first surface and the second surface of the glass substrate 2 via the adhesion layer 5 , respectively. Therefore, the wiring substrate 1 constitutes a double-sided wiring substrate. The first surface and the second surface of the glass substrate 2 are in a relationship of a front surface and a back surface. exist figure 1 Herein, the lower surface of the glass substrate 2 is defined as the first surface, and the upper surface of the glass substrate 2 is defined as the second surface. The wirin...

no. 2 Embodiment approach )

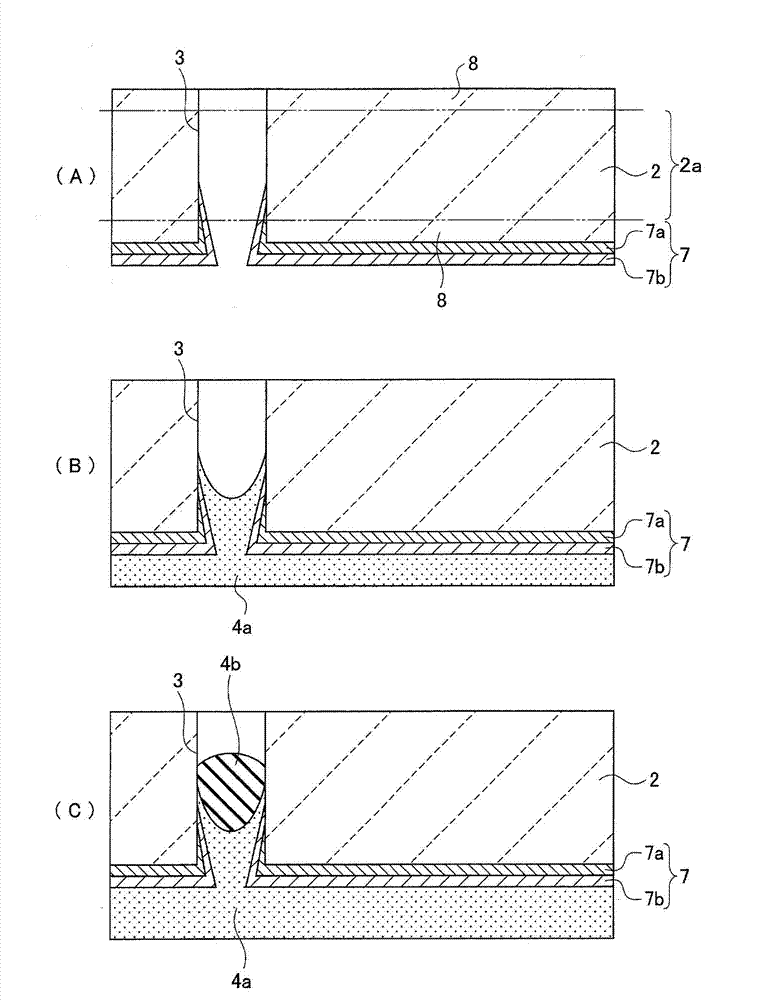

[0125] Hereinafter, the substrate manufacturing method and the wiring substrate manufacturing method according to the second embodiment of the present invention will be described based on the drawings. Figure 10 A flowchart showing the wiring board manufacturing method according to the present embodiment, Figure 8 It shows process diagrams from the plating base layer forming process S20 to the metal filling process S40. Additionally, if Figure 10 As shown in the flow chart of , the present embodiment differs from the first embodiment in that the fourth step (metal filling step S40 ) is divided into a planarization step S41 and a filling step S42 . The other steps are the same as those of the first embodiment, and therefore detailed descriptions are omitted.

[0126] The metal filling step S40 of this embodiment is as follows: Figure 8 As shown in (B), the surface inside the through-hole 3 of the first plating layer 4 a formed in the opening sealing step S30 (the second ...

no. 3 Embodiment approach )

[0159] This embodiment is as Figure 11 What is shown is an embodiment related to a method of manufacturing a substrate 2 in which the distribution density of the through-holes 3 has a sparse region 9a and a dense region 9b. First, the relationship between the formation state of the through-hole and the electrolytic plating, which is most relevant to the present embodiment, will be described. Among them, the substrate manufacturing method of this embodiment has the same Figure 10 The manufacturing process is the same as that of the second embodiment shown, and therefore detailed descriptions of the respective manufacturing processes are omitted.

[0160] In the present embodiment, a plurality of through-holes 3 to be filled with metal by electrolytic plating are provided on the glass substrate 2 . Furthermore, on the glass substrate 2, a region 9a in which the through-holes 3 are sparsely distributed and a region 9b in which the through-holes 3 are densely distributed are m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com