High-heat-resistance polycarbonate (PC)/acrylonitrile styrene acrylate copolymer (ASA) alloy material and preparation method thereof

An alloy material and high heat-resistant technology, applied in the field of high heat-resistant PC/ASA alloy material and its preparation, can solve the problems of poor weather resistance of ABS resin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

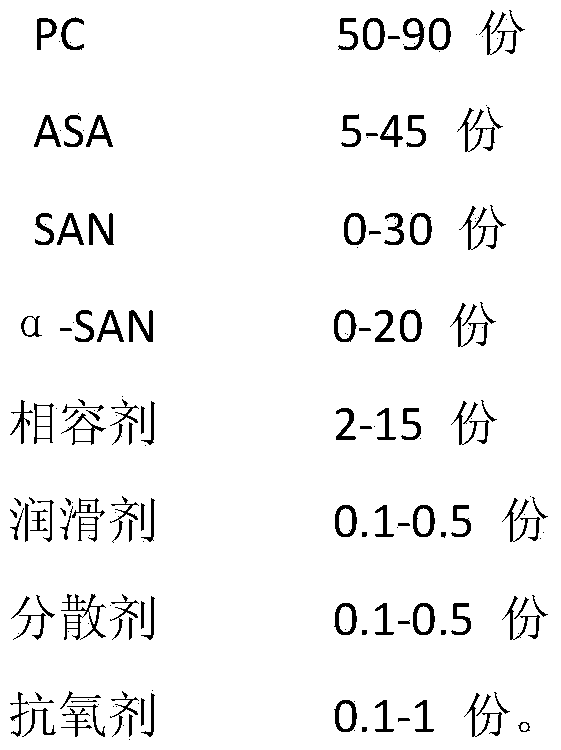

Method used

Image

Examples

Embodiment 1

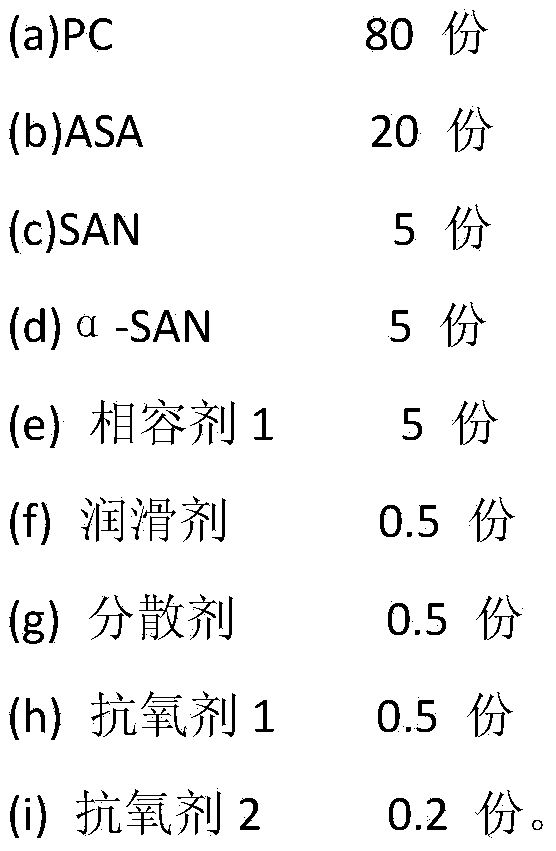

[0039] The formula is as follows:

[0040]

[0041] The main raw materials used in embodiment 1 are as follows:

[0042] PC is PC2805 produced by BAYER Company in Germany; ASA is a mixture of 777K produced by BASF Company in Germany and ASA powder from UMG in Japan; SAN is 368R produced by BASF; α‐SAN is a self-made product in the laboratory; compatibilizer 1 is ABS Grafted maleic anhydride (ABS‐g‐MAH).

[0043] The formula in Example 1 was added to the high-speed mixer in proportion and stirred for 4 minutes before discharging, then granulated with a twin-screw extruder, the screw speed of the extruder was 150-500 rpm, and the processing temperature was 210°C. ‐270°C, after extrusion, cooling, drying, and pelletizing to obtain PC / ASA alloy.

Embodiment 2

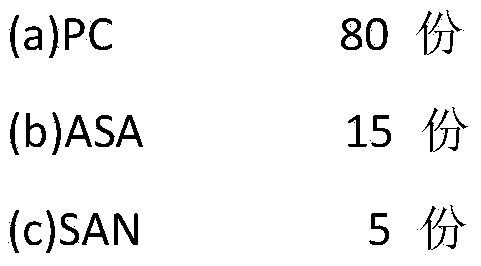

[0045] The formula is as follows:

[0046]

[0047]

[0048] The main raw materials used in embodiment 2 are as follows:

[0049] PC is PC2805 produced by BAYER Company of Germany; ASA is a mixture of 778T produced by BASF Company of Germany and LI 913 produced by Kumho Company; SAN is PN117 produced by Chimei; α‐SAN is a self-made product in the laboratory; compatibilizer 2 is A graft copolymer of ASA and maleic anhydride (ASA‐g‐MAH), a graft copolymer of styrene and maleic anhydride (SMA).

[0050] The formula in Example 2 was added to the high-speed mixer in proportion and stirred for 4 minutes before discharging, then granulated with a twin-screw extruder, the screw speed of the extruder was 150-500 rpm, and the processing temperature was 210°C. ‐270°C, after extrusion, cooling, drying, and pelletizing to obtain PC / ASA alloy.

Embodiment 3

[0052] The formula is as follows:

[0053]

[0054] The main raw materials used in embodiment 3 are as follows:

[0055] PC is PC2805 produced by BAYER Company in Germany; ASA is a mixture of 778T produced by BASF Company in Germany and ASA powder from UMG in Japan; SAN is 368R produced by BASF; α‐SAN is a self-made product in the laboratory; compatibilizer 3 is ABS Blend of grafted maleic anhydride (ABS‐g‐MAH), styrene and graft copolymer of maleic anhydride (SMA).

[0056] The formula in Example 3 was added to the high-speed mixer in proportion and stirred for 4 minutes before discharging, then granulated with a twin-screw extruder, the screw speed of the extruder was 150-500 rpm, and the processing temperature was 210°C. ‐270°C, after extrusion, cooling, drying, and pelletizing to obtain PC / ASA alloy.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com