frp sheet anchor and its anchoring method

A technology of FRP sheets and anchors, applied in the processing of building materials, structural elements, building components, etc., can solve the problems of corrosion and the inability to give full play to the unique advantages of FRP

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Below in conjunction with accompanying drawing and example describe in detail:

[0034] 1. FRP sheet anchorage

[0035] 1. Overall

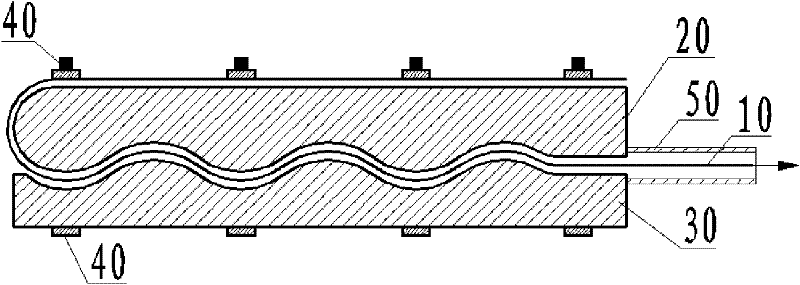

[0036] Such as figure 1 , the present invention includes a sheet 10, an upper anchor plate 20, a lower anchor plate 30 and a bolt 40;

[0037] The sheet 10 is placed between the upper anchor plate 20 and the lower anchor plate 30, the upper anchor plate 20 and the lower anchor plate 30 clamp the sheet 10 together, and the bolt 40 passes through the plate holes of the upper anchor plate 20 and the lower anchor plate 30 25 anchors the upper anchor plate 20 and the lower anchor plate 30 tightly.

[0038] When necessary, corrugated pipes 50 are connected at both ends of the anchorage, and the sheet 10 passes through the corrugated pipes 50 .

[0039] 2. Functional components

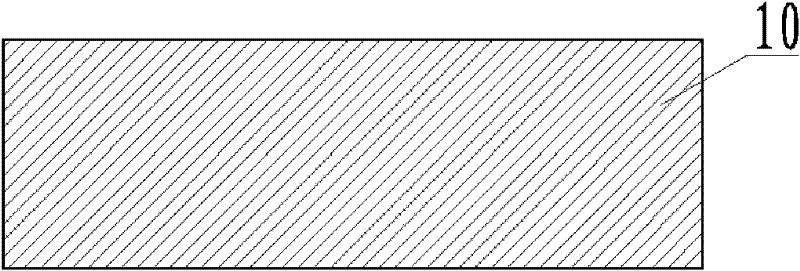

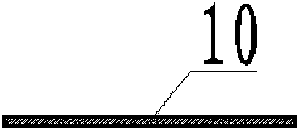

[0040] 1) Sheet 10

[0041] Such as Figure 2.1 , Figure 2.2 , the sheet 10 is either an FRP sheet or an FRP cloth, which is a thin-walled strip structu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com