Engineering modularized manufacturing system and engineering modularized manufacturing method

A manufacturing system and manufacturing method technology, applied in the field of engineering, to achieve the effect of reducing construction difficulty, shortening construction period, and reducing installation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

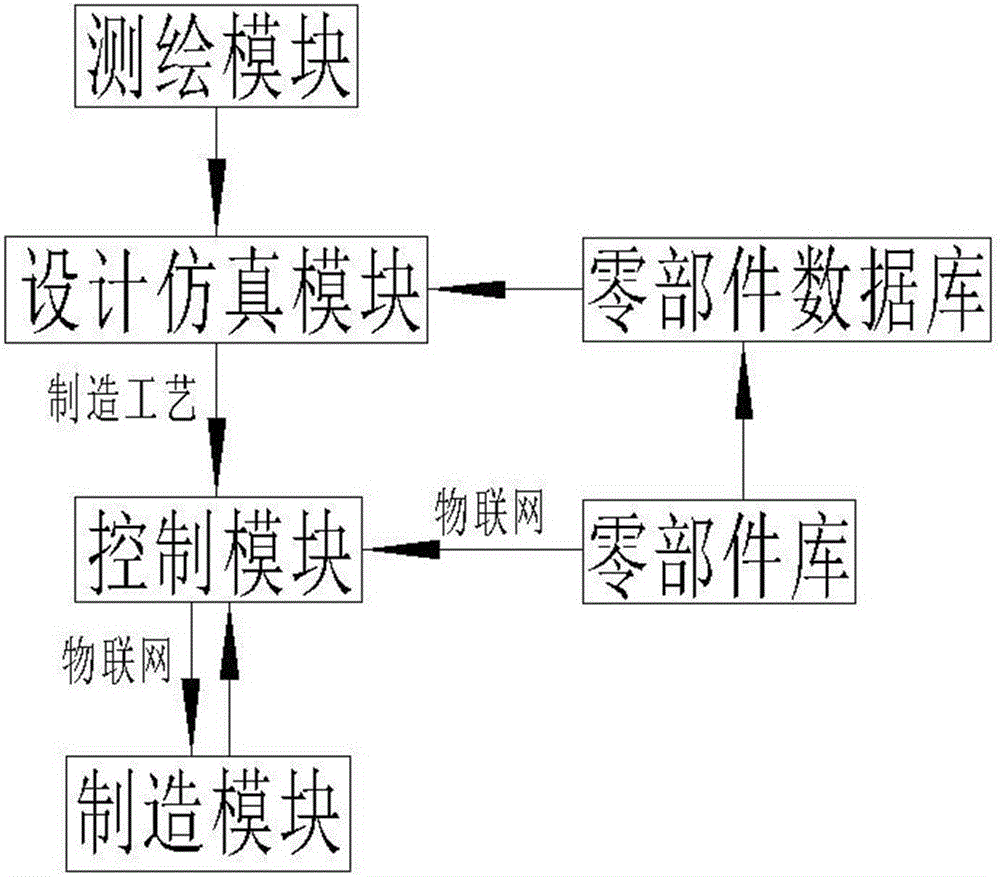

[0038] Such as figure 1 As shown, an engineering modular manufacturing system includes a surveying and mapping module, a design simulation module, a parts library, a manufacturing module, the Internet of Things and a control module, and the control module is respectively connected with the design simulation module, the surveying and mapping module, the parts library and the manufacturing module;

[0039] The surveying and mapping module is used to survey and map the topography of the construction site or the spatial structure of various actual environments and buildings;

[0040] The design simulation module is used to design engineering design drawings on the basis of various spatial structures obtained by the surveying and mapping module, and simulate accurate three-dimensional engineering structures and corresponding engineering construction process plans according to the engineering design drawings;

[0041] The control module is used to control and coordinate the orderly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com