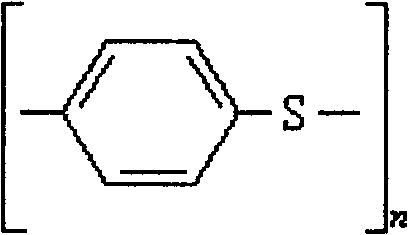

High temperature-resistant high-strength polyphenylene sulfide-based reactively reinforced and toughened composite material

A polyphenylene sulfide-based, reinforced and toughened technology, which is applied in the field of high-temperature-resistant, high-strength polyphenylene sulfide-based reactive reinforced and toughened composite materials, can solve the problem of decreased rigidity and heat resistance, and poor bonding between rubber and the substrate , the toughening effect is not obvious, etc., to achieve the effects of improved toughness, easy molding, and good dimensional stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

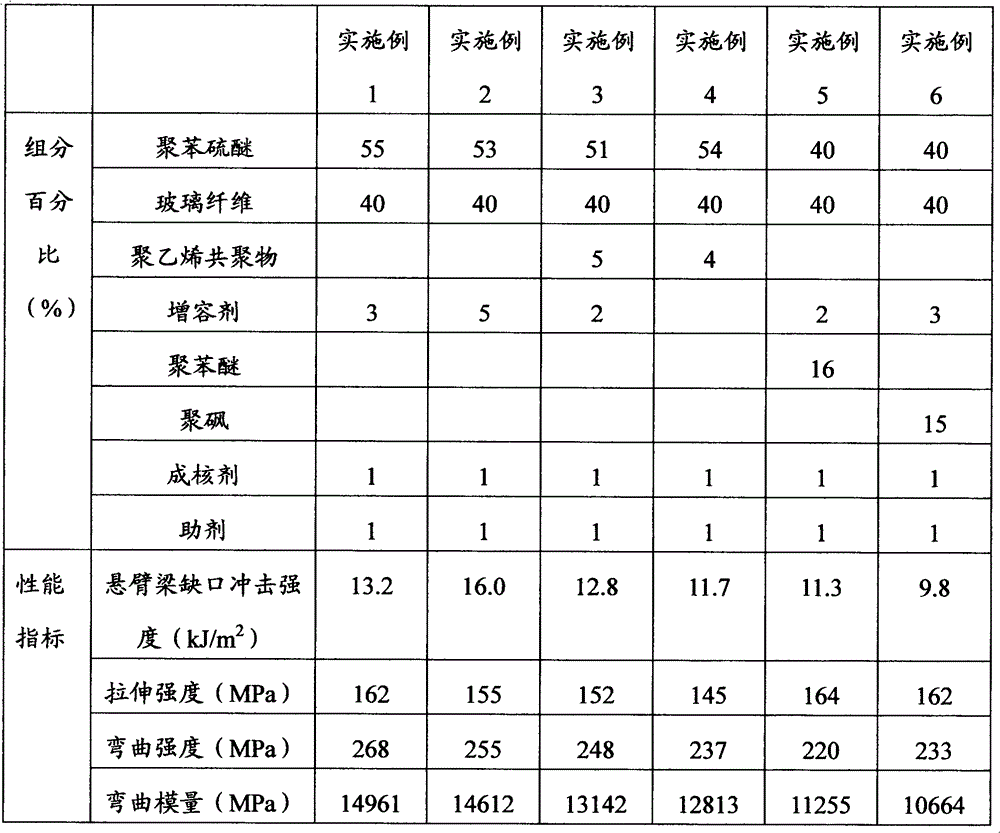

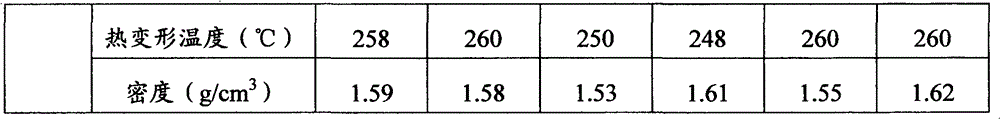

Embodiment 1~6

[0040] Heat treatment of polyphenylene sulfide in an oven at 220 to 240 ° C for 4 to 10 hours, and it is advisable to test its melt index to reach 300 to 500 g / 10min. After weighing the pretreated polyphenylene sulfide in proportion, add it to a high-speed mixer, then add a coupling agent and a nucleating agent, and stir evenly. The stirring speed is about 1440 rpm, and the stirring time is 1 minute. Add compatibilizer, polyolefin, high-performance engineering plastics and auxiliaries into the machine and stir evenly at a stirring speed of about 720 rpm for 3 minutes to obtain a premix.

[0041] The set process conditions of the twin stud extruder are as follows:

[0042] The temperature control of the screw and the head of the 1~9 zone is: 260~290℃;

[0043] Screw speed: 400 ~ 500 rpm;

[0044] Vacuum degree: -0.09~-0.06MPa.

[0045] The above-mentioned premix is added to the main feeding hopper of the twin-screw extruder, and the glass fiber is added from the side feedi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com