Preparation method for modified polyarylether

A polyarylene ether and modification technology, applied in the field of preparation of modified polyarylene ether, can solve the problems of poor control of polysulfone segment length and product molecular weight, harsh reaction conditions, and high equipment requirements, and achieve good chemical stability. The effect of high stability, mild reaction conditions and low preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

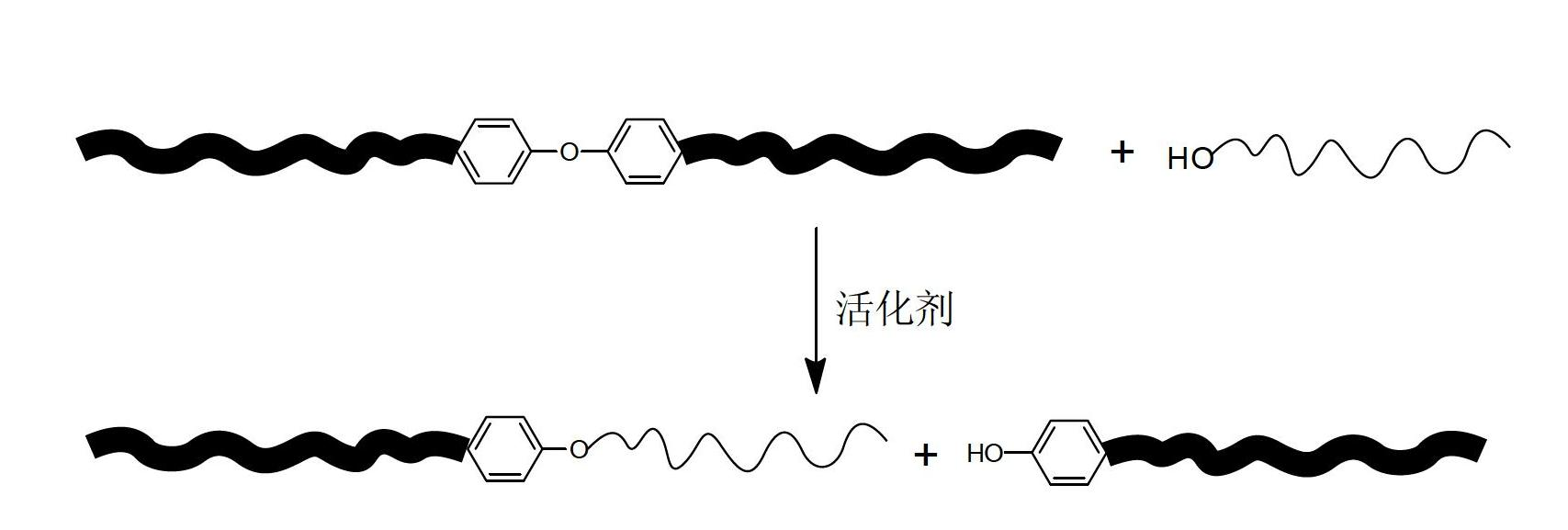

[0061] Embodiment 1: Preparation of monohydroxy polyethylene glycol modified polysulfone

[0062] Add 44.25g of polysulfone and 20.00g (containing 4.00mmol of hydroxyl) of monohydroxypolyethylene glycol (molecular weight: 5000 g / mol) into 440.00g of tetrahydrofuran, and mechanically stir for 5 hours at 50°C to dissolve completely , cooled to room temperature. 0.11 g of sodium (4.78 mmol) was added as a proton-removing agent, and the reaction was stirred at 20° C. for 12 hours, and dilute hydrochloric acid was added dropwise to the reaction system to terminate the reaction. The reaction solution is poured into deionized water to precipitate the product, the product is filtered, pulverized, washed with deionized water for several times, and then dried to obtain monohydroxy polyethylene glycol modified polysulfone. 62.52 g of product were weighed for a 97.3% yield of the reaction.

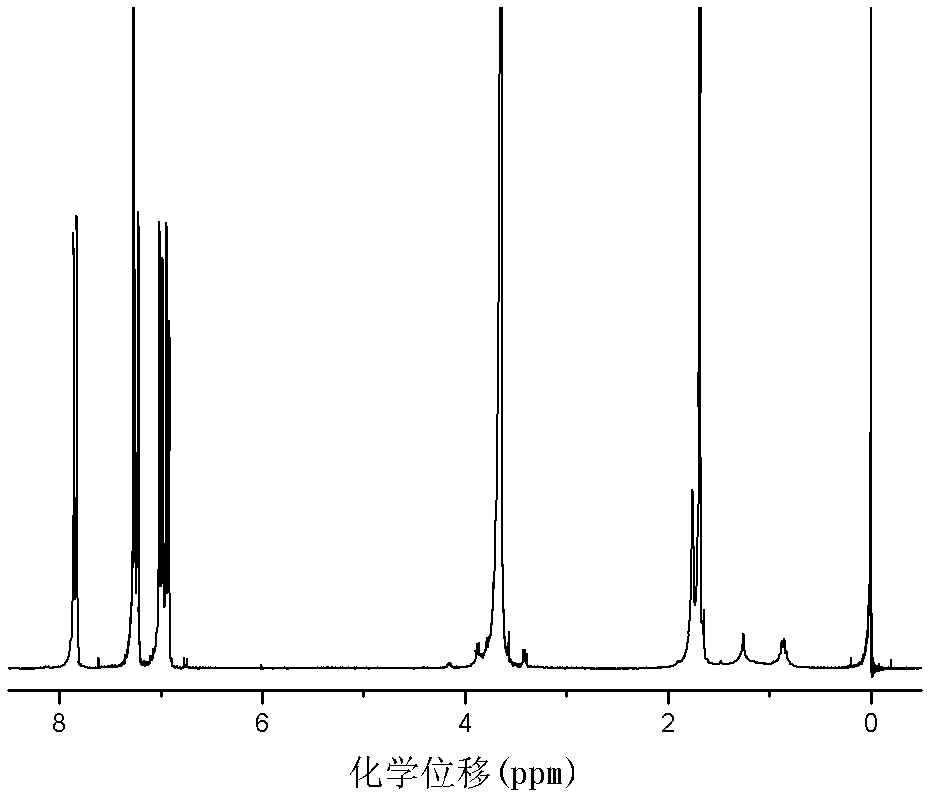

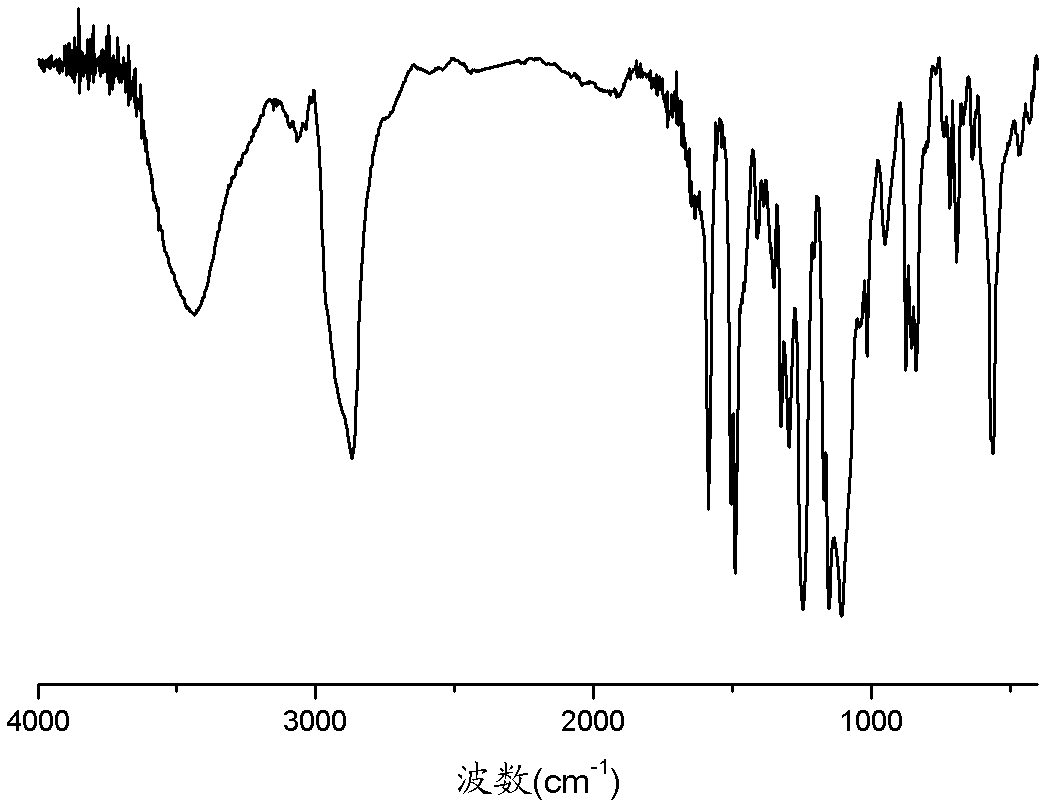

[0063] The proton nuclear magnetic resonance spectrum figure of the monohydroxypolyethylene glyc...

Embodiment 2

[0070] Embodiment 2: Preparation of polyethylene glycol modified polyethersulfone

[0071] Add 40.00g of polyethersulfone and 18.00g (containing 3.60mmol of hydroxyl) of polyethylene glycol (molecular weight: 10,000 g / mol) to 440.00g of sulfolane, and stir mechanically at 40°C for 6 hours to dissolve completely. Let cool to room temperature. 0.18 g (4.50 mmol) of potassium hydride was added as a proton-removing agent, the reaction was stirred at 10° C. for 1 hour, and glacial acetic acid was added dropwise to the reaction system to terminate the reaction. The reaction solution is poured into methanol to precipitate the product, the product is filtered, pulverized, washed with deionized water for several times, and then dried to obtain polyethylene glycol-modified polyethersulfone. Weighed 57.13 g of product, the yield of the reaction was 98.5%.

[0072] The hydrogen nuclear magnetic resonance spectrum of the polyethylene glycol modified polyethersulfone obtained in this emb...

Embodiment 3

[0077] Example 3: Preparation of Polypropylene Glycol Modified Polyarylether Sulfone

[0078] Add 40.00g polyarylethersulfone and 160.00g (containing 80.00mmol hydroxyl) polypropylene glycol (molecular weight: 4000 g / mol) to 1500.00g N,N-dimethylformamide, mechanically stir at 80°C 5 hours to make it dissolve completely, and cool to room temperature. 1.10 g (8.00 mmol) of potassium carbonate was added as a proton-removing agent, the reaction was stirred at 220° C. for 18 hours, and the reaction was terminated by cooling to room temperature. The reaction solution is poured into ether to precipitate the product, and the product is filtered, pulverized, washed with deionized water for several times, and then dried to obtain the polypropylene glycol modified polyarylethersulfone. 180.80 g of product was weighed for a 90.4% yield of the reaction.

[0079] The polypropylene glycol content in the modified polyarylethersulfone can be calculated to be 78.8wt% by proton nuclear magne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com