Precision forming mold for engineering composite material transmission pieces

An engineering composite material and precision forming technology, which is applied in the field of precision forming molds for engineering composite transmission parts, can solve the problems of long hot press vulcanization time, difficult quality assurance, low heat utilization rate, etc., to reduce hot press vulcanization time, Ensure good uniformity and product compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

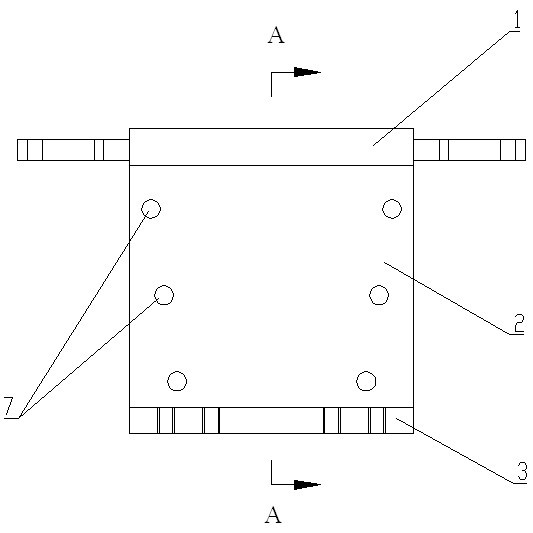

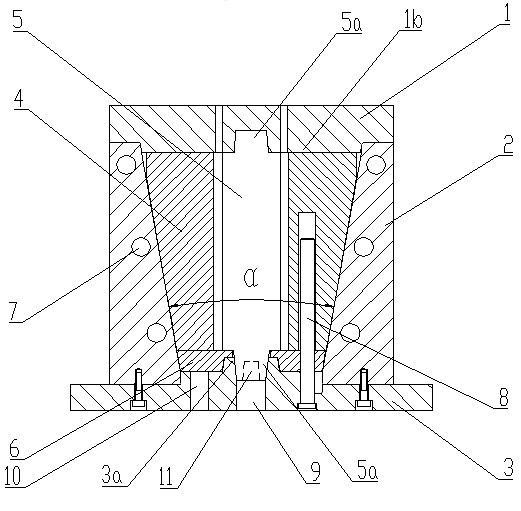

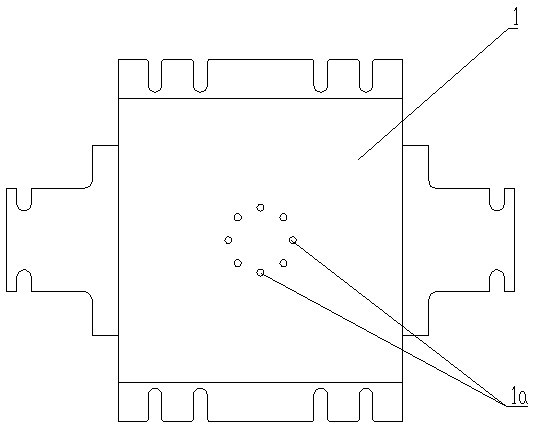

[0029] The present invention will be described in detail below in conjunction with the accompanying drawings: the precision forming mold for engineering composite transmission parts of this embodiment is used to produce cylindrical workpieces, and includes an upper mold 1, a middle mold 2, and a lower mold arranged in sequence from top to bottom. 3. The mold body 4 arranged in the middle mold 2, the mold core 5 arranged in the mold body 4 and the tray 6 arranged between the mold body 4 and the lower mold 2 and the mold core 5, that is, the mold core and the mold body are both Placed on the tray, the upper mold 1, the mold body 2, the mold core 5 and the tray 6 jointly enclose the molding cavity, and the mold core and the mold body are concentrically arranged to form a ring-shaped cavity. The upper mold 1 is provided with a pouring port 1a communicating with the cavity, and the pouring ports are multiple evenly distributed around the axis of the cavity for injection of materials...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com