High-performance engineering plastic/polyester type TPU (thermoplastic polyurethane) alloy material and preparation method thereof

A technology of engineering plastics and alloy materials, applied in the field of material science, can solve problems such as small melt index, restriction, and poor fluidity, and achieve the effects of improving fluidity, convenient operation, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

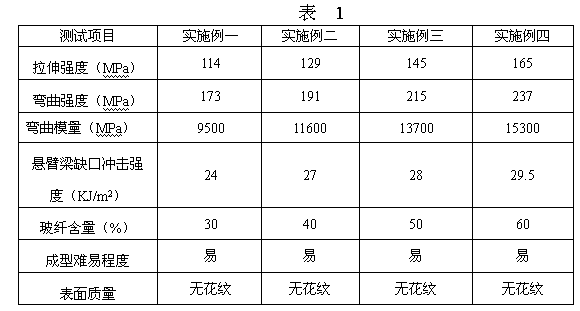

Embodiment 1

[0015] Embodiment 1 of the present invention: High-strength and high-toughness TPU and styrene-based composite material, calculated in parts by mass, including 25 parts of polyester TPU, 30 parts of long glass fiber, 45 parts of engineering plastics, and styrene-maleic anhydride copolymer 3 parts, 0.6 parts of fluidity aid, 1.2 parts of chain extender and 0.6 parts of antioxidant.

[0016] The grade of TPU is 2103-80AE, the melt flow rate is 25-55g / 10min (200℃ / 2.16Kg), and the Shore hardness (A) of TPU is 65-85;

[0017] The grade of glass fiber is 4501, with a diameter of 17 microns, Chongqing Compound International Company; the grade of styrene-maleic anhydride copolymer is SMA218; the grade of fluidity aid is ADP-1200; the grade of chain extender is ADR4300S; The grade of the oxygen agent is PUB350.

[0018] The preparation method of high-strength and high-toughness TPU and styrene-based composite material is to get each component according to the above-mentioned mass part...

Embodiment 2

[0021] Embodiment 2 of the present invention: High-strength and high-toughness TPU and styrene-based composite material, calculated in parts by mass, including 20 parts of polyester TPU, 40 parts of long glass fiber, 40 parts of styrene-based resin, styrene-maleic anhydride 4 parts of copolymer, 0.6 part of flow aid, 0.9 part of chain extender and 0.5 part of antioxidant.

[0022] The preparation method is the same as in Example 1.

Embodiment 3

[0023] Example 3 of the present invention: High-strength and high-toughness TPU and styrene-based composite material, calculated in parts by mass, including 18 parts of polyester TPU, 50 parts of long glass fiber, 32 parts of engineering plastics, and styrene-maleic anhydride copolymer 5 parts, 0.5 part of flow aid, 0.8 part of chain extender and 0.5 part of antioxidant.

[0024] The preparation method is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt flow rate | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com