A wetting method of a hard shell lithium ion battery

A lithium-ion battery, hard case technology, applied in secondary batteries, battery pack parts, non-aqueous electrolyte batteries, etc., can solve problems such as electrolyte spillage, reduce spillage, avoid electrolyte spillage, and improve infiltration efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

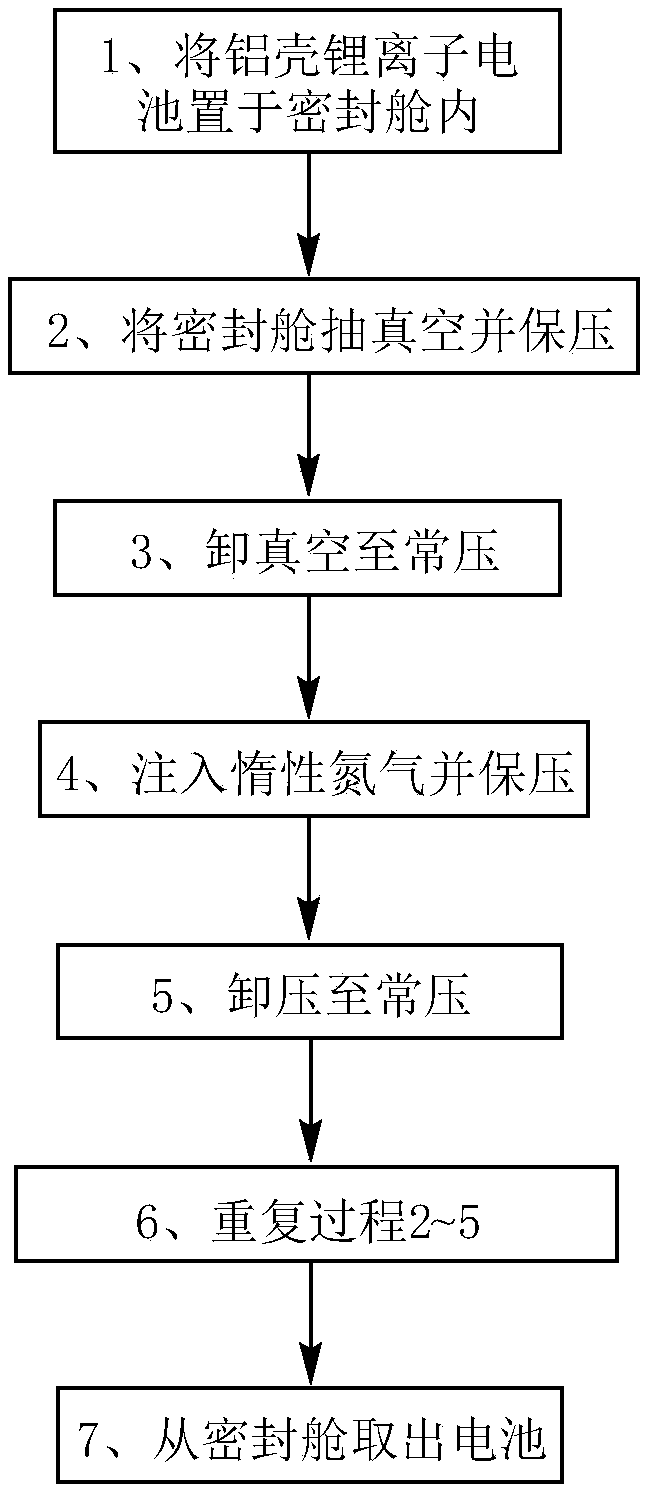

[0040] The infiltration method of the hard shell lithium ion battery of the present embodiment includes the following steps:

[0041] 1) After placing the open aluminum shell lithium-ion battery in the sealed chamber, evacuated the sealed chamber to -60KPa gauge pressure, and maintained the pressure for 2 minutes; then depressurized the sealed chamber to normal pressure and injected dry nitrogen to the gauge pressure is 0.2MPa, and the pressure is maintained for 2min;

[0042] 2) After step 1) is completed, the airtight chamber is depressurized to normal pressure, vacuumed again to a gauge pressure of -80KPa, and the pressure is maintained for 3 minutes; then the airtight chamber is depressurized to normal pressure and then injected into dry nitrogen to a gauge pressure of 0.4 MPa, holding pressure for 3min;

[0043] 3) After step 2) is completed, the airtight chamber is depressurized to normal pressure again, the airtight chamber is evacuated to a gauge pressure of -99KPa, a...

Embodiment 2

[0046] The infiltration method of the hard shell lithium ion battery of the present embodiment includes the following steps:

[0047] 1) After placing the open aluminum shell lithium-ion battery in the sealed chamber, vacuum the sealed chamber to a gauge pressure of -70KPa, and keep the pressure for 2 minutes; then continue to vacuum the sealed chamber to -99KPa, and keep the pressure for 2 minutes; then seal the After the cabin is depressurized to normal pressure, fill in dry nitrogen until the gauge pressure is 0.6MPa, and keep the pressure for 2min;

[0048] 2) Repeat step 1) 10 times, the infiltration process is completed, open the sealed hatch, and remove the battery for blanking.

Embodiment 3

[0050] The infiltration method of the hard shell lithium ion battery of the present embodiment includes the following steps:

[0051] 1) After placing the open aluminum shell lithium ion battery in the sealed chamber, evacuated the sealed chamber to the gauge pressure of -30KPa, and maintained the pressure for 0.2min; The pressure is 0.1MPa, and the pressure is maintained for 0.2min;

[0052] 2) After step 1) is completed, the airtight chamber is depressurized to normal pressure, evacuated again to a gauge pressure of -40KPa, and the pressure is maintained for 3 minutes; then the airtight chamber is depressurized to normal pressure and then injected into dry nitrogen to a gauge pressure of 0.2 MPa, holding pressure for 3min;

[0053] 3) After step 2) is completed, the airtight chamber is depressurized to normal pressure again, the airtight chamber is evacuated to a gauge pressure of -50KPa, and the pressure is maintained for 5min; then the airtight chamber is depressurized to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com