A disc feeding system with controllable feeding volume

A feeding system and disc feeder technology, applied in loading/unloading, conveyors, rotary conveyors, etc., can solve the problem of random throwing of materials, difficulty in meeting batching requirements, and uncontrollable feeding volume, etc. problems, to achieve the effect of sustainable development of the environment, accurate, stable and reliable feeding, and improving the ability of feeding and batching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can understand the solution of the present invention more clearly, but the protection scope of the present invention is not limited thereby.

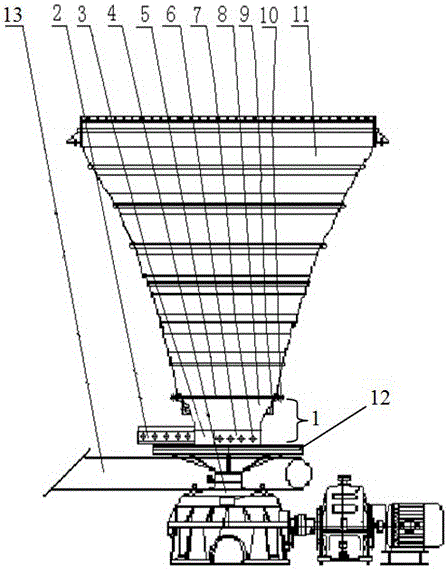

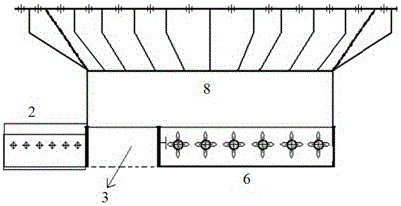

[0022] as attached figure 1 As shown, the whole of the disc feeding system with controllable feeding amount of the present invention includes: a feed bin 11, a feeding sleeve 1 and a disc feeder 4, and the top opening of the feed bin 11 is directly connected to the material source, the bottom outlet of the silo 11 is connected to the feed sleeve 1, and the bottom outlet of the feed sleeve 1 is on the disk surface of the rotating disc 12 in the disc feeder 4, and the feed sleeve 1 is arranged between the disc feeder 4 and the silo 11, and the material in the silo 11 is supplied to the rotating disc 12 of the disc feeder through the feeding sleeve 1, under the rotating dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com