Membrane electrode for improving voltage distribution uniformity

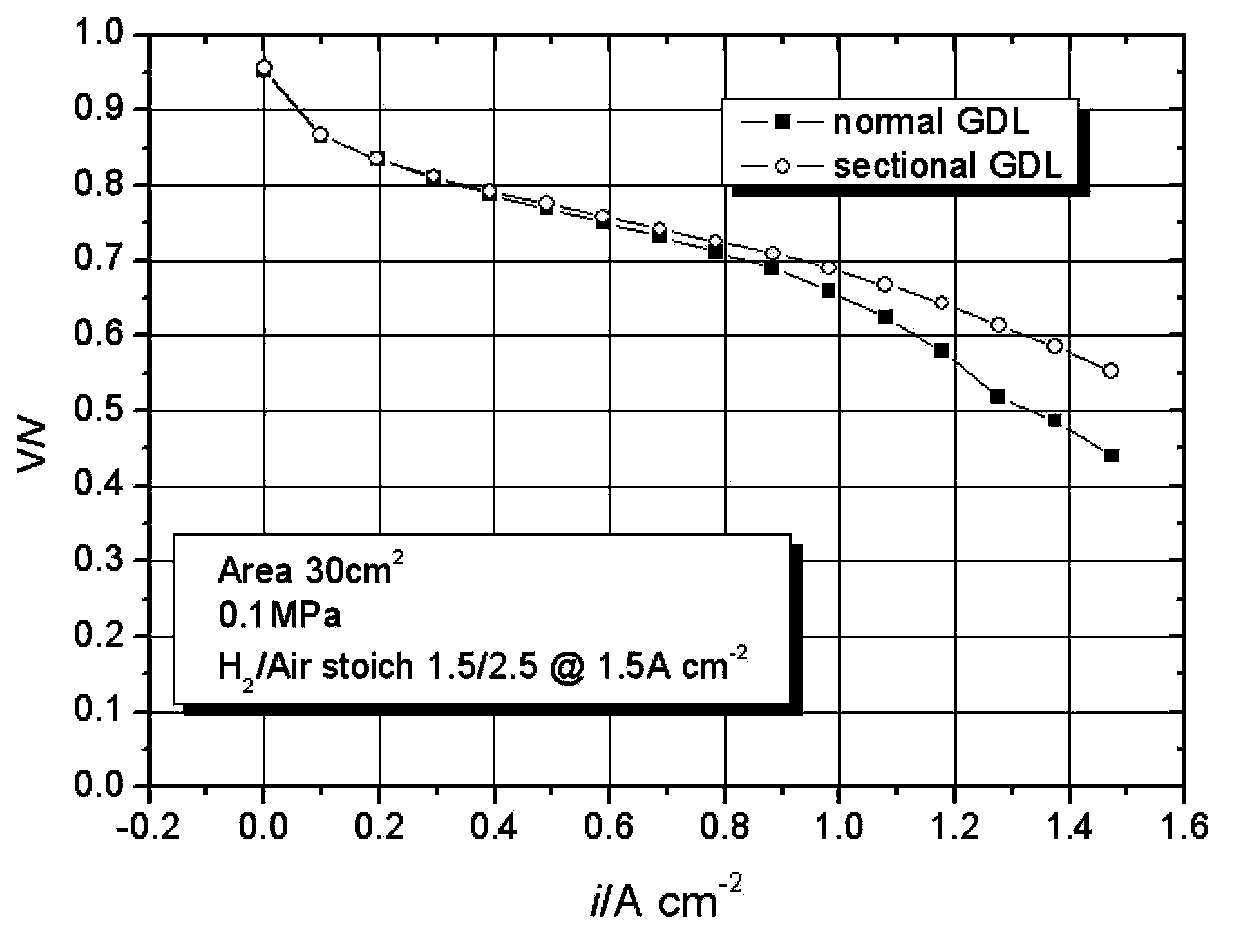

A membrane electrode and electrode technology, applied in battery electrodes, circuits, fuel cells, etc., can solve the problem of uneven voltage distribution on the electrode surface, achieve the effects of improving water flooding, improving hydrophobicity, and improving output performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

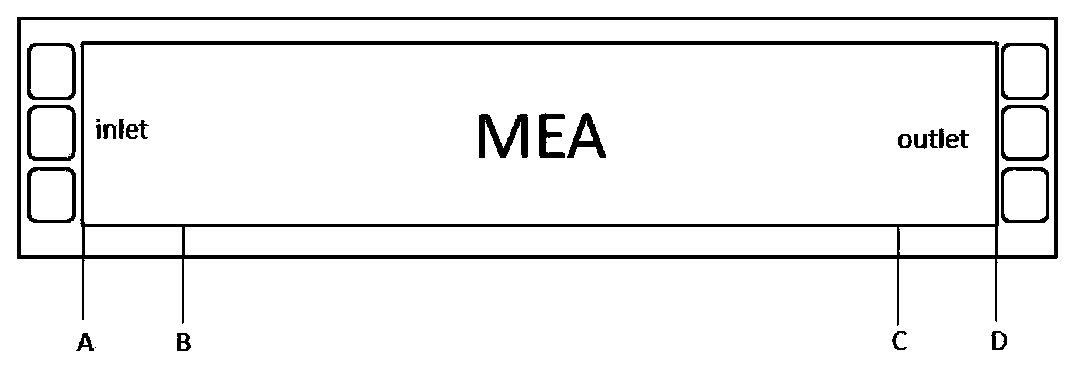

[0018] Hydrophobic treatment of carbon paper: take an area of 10*30cm 2 Toray TGP-H060 carbon paper, such as figure 1 , The carbon paper is evenly soaked in 2wt.% PTFE emulsion, and the soaked carbon paper is baked at 240-340° under the protection of nitrogen to achieve hydrophobicity. After firing, PTFE accounts for 5wt.% of the total weight of carbon paper and PTFE.

[0019] Microporous layer treatment: Divide the carbon paper from the electrode inlet end A to the electrode outlet end D into 4 partitions equally according to the length, and brush the carbon powder slurry containing 5% PTFE on the first partition from the inlet end (that is, PTFE Accounting for 5% of the total weight of PTFE and toner), the second partition is brushed with 12% PTFE toner slurry (that is, PTFE accounts for 12% of the total weight of PTFE and toner), and the third partition is brushed with 20% PTFE The toner slurry (that is, PTFE accounts for 20% of the total weight of PTFE and toner), and ...

Embodiment 2

[0024] 3*10cm 2 The carbon paper is divided into 3 partitions. The first partition is soaked with PTFE to make the content reach 3% (that is, PTFE accounts for 3% of the total weight of carbon paper and PTFE in this area), and the second partition contains 10% PTFE (that is, PTFE accounts for 3% of the total weight of carbon paper and PTFE in this area). 10% of the total weight of carbon paper and PTFE in the area), and the content of PTFE in the third zone is 18% (that is, PTFE accounts for 18% of the total weight of carbon paper and PTFE in this area).

[0025] Scrape-coat toner pastes with different PTFE contents on the three partitions of the carbon paper. The microporous layer of the first partition contains PTFE10% (that is, PTFE accounts for 10% of the total weight of the carbon powder and PTFE in this area), and the second The partitioned microporous layer contains 20% PTFE (that is, PTFE accounts for 20% of the total weight of toner and PTFE in this area), and the thi...

n proportion 3

[0026] Select two Nafion212 membranes, spray a uniform anode catalytic layer (Pt to Nafion ratio 3:1, PTFE-free) on one side of one of the membranes, and spray a cathode partitioned catalytic layer on one side of the other membrane. Specific method: Divide the membrane into three partitions accordingly. The first partition is sprayed with catalyst slurry containing 1% PTFE (that is, PTFE accounts for 1% of the total weight of PTFE, catalyst and Nafion resin), and the second partition is sprayed with 5% PTFE catalyst slurry (i.e. PTFE accounts for 5% of the total weight of PTFE, catalyst and Nafion resin), and the third partition is sprayed with catalyst slurry containing 8% PTFE (i.e. PTFE accounts for 8% of the total weight of PTFE, catalyst and Nafion resin) . The weight ratio of catalyst to Nafion is 3:1, and the sum of the two accounts for 99%, 95%, and 92% of the total weight in the 1-3 partitions:

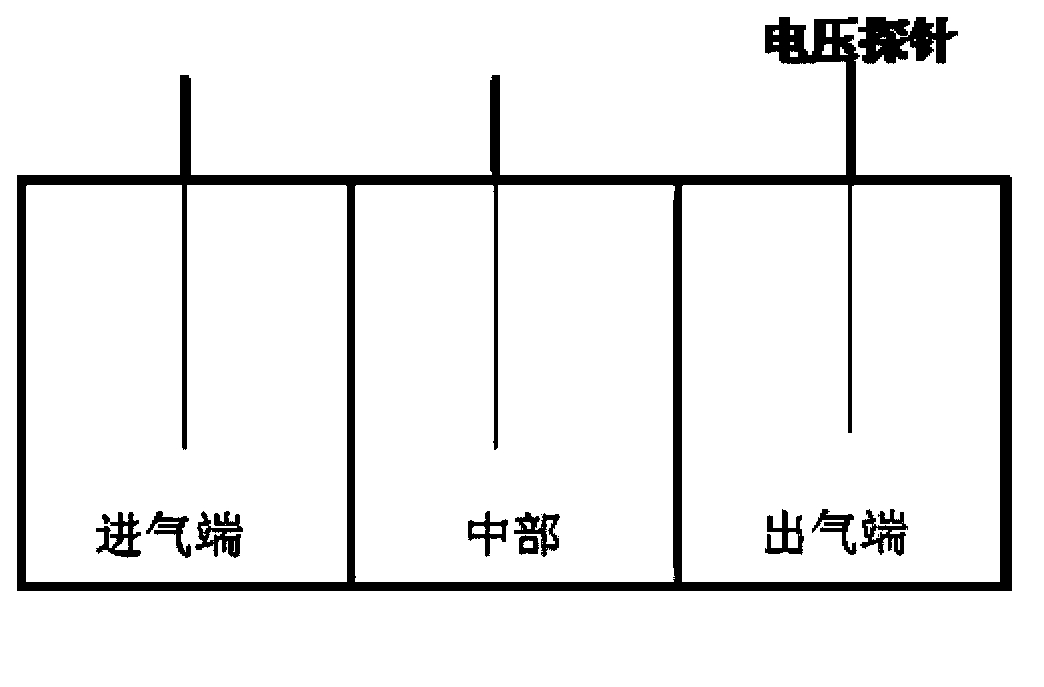

[0027] Select three copper wires with a diameter of 20 microns, and san...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com