High heat conductivity copper clad laminate

A technology of copper clad laminates and high thermal conductivity, applied in the field of copper clad laminates, can solve the problems of inability to mass production, decreased light output efficiency, shortened service life, etc. The effect of thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

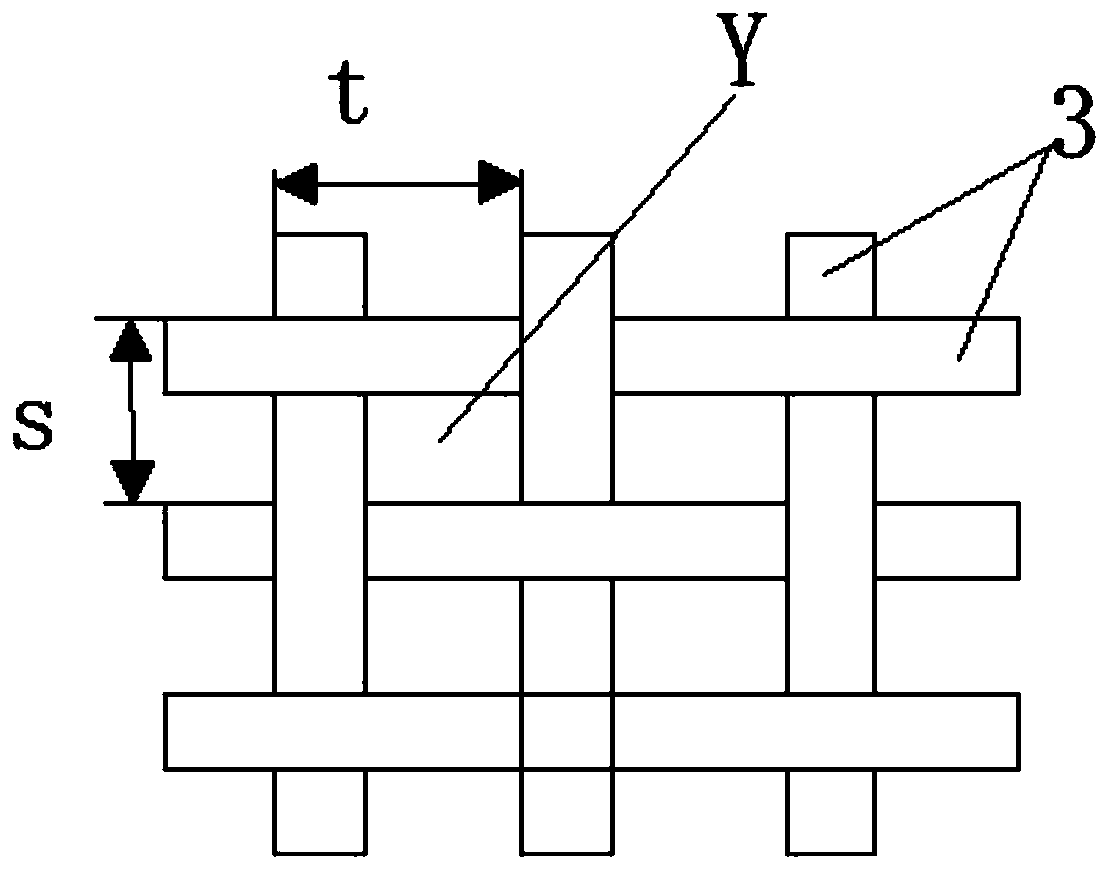

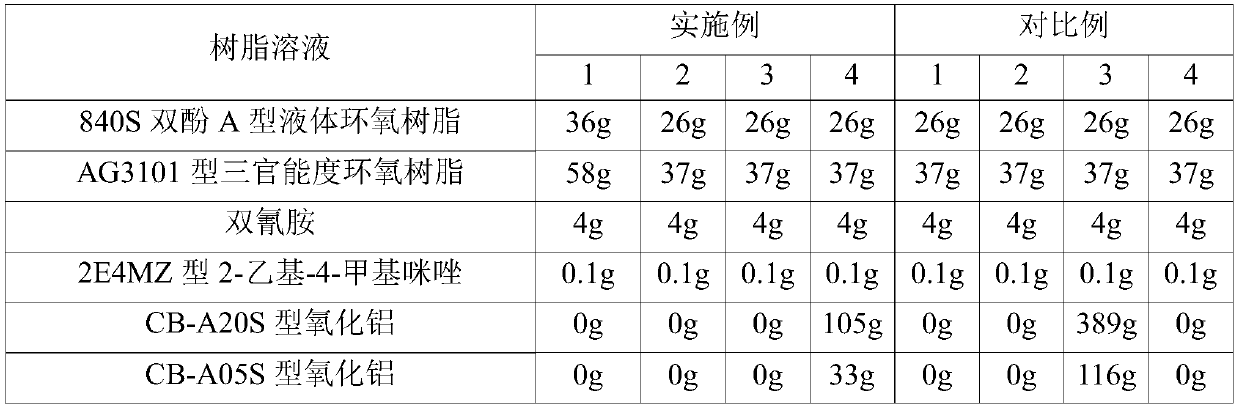

[0036] Prepare the resin solution according to the formula in Table 1, impregnate the 1080 type E glass fiber cloth with a thickness of 60 μm with the prepared resin solution, the diameter of this glass fiber is 5 μm, and the weaving density is: 60 yarns / 25mm in the longitudinal direction and 46 yarns in the transverse direction / 25mm; drying at 120°C-160°C for 5-10 minutes to obtain a porous prepreg with a porosity of 75%.

[0037] Prepare the resin resin solution according to the formula in Table 2, and then evenly coat it on a polyester film with a thickness of 75 μm, and dry it at 120-140°C for 5-10 minutes to obtain a high thermal conductivity resin film of about 100 μm.

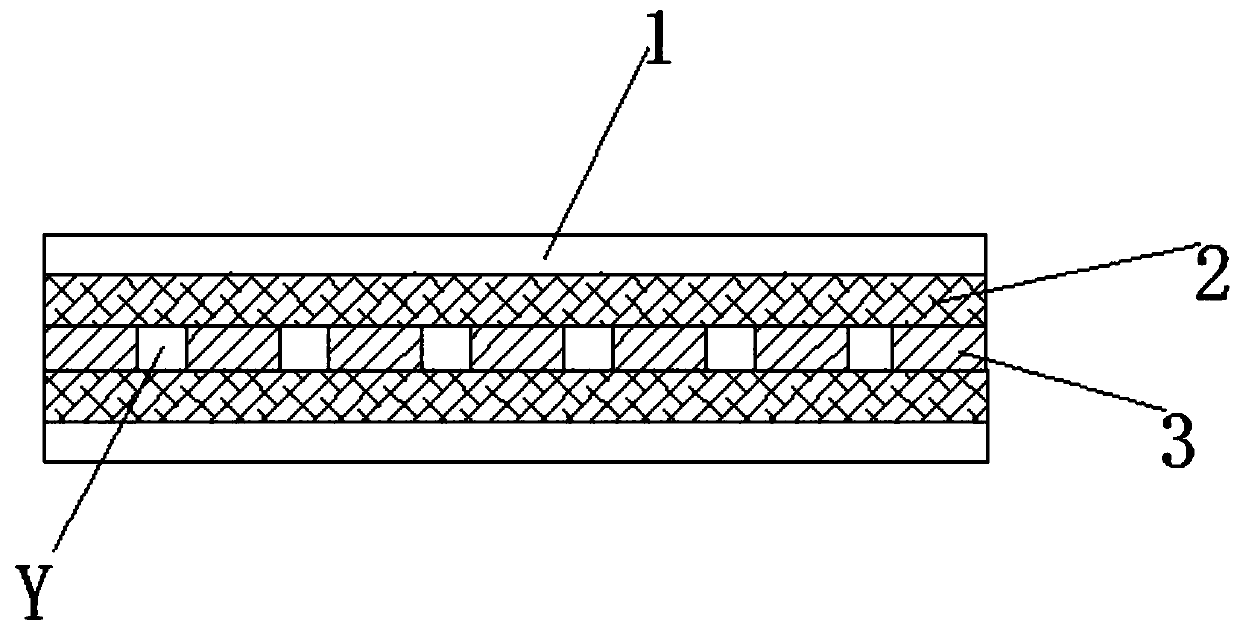

[0038] Such as figure 1 As shown, the high thermal conductivity resin film 2 is laminated on both sides of the multi-void prepreg 3. After lamination, a piece of 35 μm copper foil 1 is placed on the upper and lower sides. At 180°C, the pressure is 40kg / cm 2 Under the condition of heating and pressing ...

Embodiment 2

[0040] Prepare the resin solution according to the formula in Table 1, impregnate the 7628 type E glass fiber cloth with a thickness of 200 μm, the weaving density is: 60 yarns / 25mm in the longitudinal direction, 47 yarns / 25mm in the transverse direction, and the diameter of the glass fiber is 9 μm; ℃ drying for 5-10 minutes to obtain a porous prepreg with a porosity of 75%.

[0041] Prepare the resin resin solution according to the formula in Table 2, and then evenly coat it on a polyester film with a thickness of 75 μm, and dry it at 120-140°C for 5-10 minutes to obtain a high thermal conductivity resin film of about 100 μm.

[0042] Such as figure 1 As shown, the high thermal conductivity resin film 2 is laminated on both sides of the multi-void prepreg 3. After lamination, a piece of 35 μm copper foil 1 is placed on the upper and lower sides. At 180°C, the pressure is 40kg / cm 2 Under the condition of heating and pressing for 90 minutes, a high thermal conductivity copper...

Embodiment 3

[0044] Prepare the resin solution according to the formula in Table 1, impregnate the 1080 type E glass fiber cloth with a thickness of 60 μm with the prepared resin solution, and dry it at 120°C-160°C for 5-10 minutes to obtain a porosity of more than 75%. Void prepreg.

[0045] Prepare the resin resin solution according to the formula in Table 2, and then evenly coat it on a polyester film with a thickness of 75 μm, and dry it at 120-140°C for 5-10 minutes to obtain a high thermal conductivity resin film of about 100 μm.

[0046] Such as figure 1 As shown, the high thermal conductivity resin film 2 is laminated on both sides of the multi-void prepreg 3. After lamination, a piece of 35 μm copper foil 1 is placed on the upper and lower sides. At 180°C, the pressure is 40kg / cm 2 Under the condition of heating and pressing for 90 minutes, a high thermal conductivity copper clad laminate is made.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com