Sliver oxide contact material with base body performance-strengthening additives as well as preparation method and product thereof

A contact material, silver oxide technology, applied in the direction of contacts, electrical components, circuits, etc., can solve problems such as difficult to meet the requirements, achieve the effect of improving wetting, improving arc ablation resistance, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] with AgLa-SnO 2 10 Materials prepared as examples

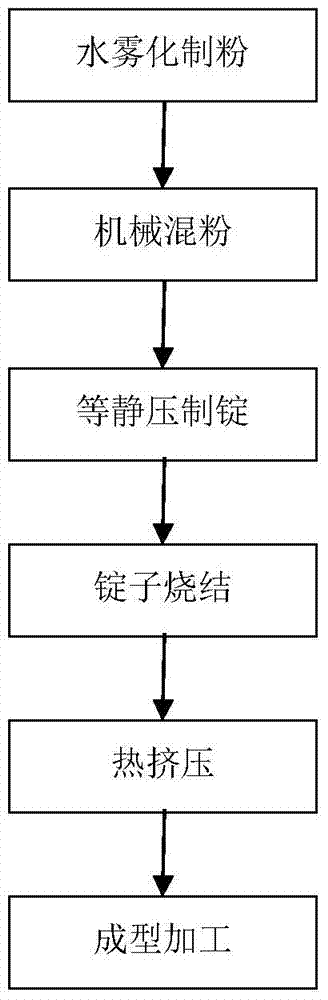

[0034] 1. 19.98kg of Ag ingot and 0.02kg of Mg were smelted at 1300°C, then water atomized at 1250°C to make powder, the water atomization pressure was 38MPa, and finally the powder was passed through a 200-mesh sieve to obtain AgLa alloy powder;

[0035] 2. 9kg of AgLa powder and 1kg of 3μm SnO 2 Preparation of AgLa-SnO by powder mechanical dry mixing 2 10 powder;

[0036] 3. AgLa-SnO 2 10 powders were made into ingots under a pressure of 180 MPa on a cold isostatic press, and the diameter of the ingots was 85 mm.

[0037] 4. AgLa-SnO 2 10 ingots were sintered under vacuum for 4 hours at a sintering temperature of 850°C.

[0038] 5. AgLa-SnO 2 10 spindles are extruded at 800°C, and the extrusion specification is Φ6.

[0039] 6. AgLa-SnO 2 10. The wire is cold drawn to the required diameter through the cold drawing machine.

[0040] The AgLa-SnO prepared in this example 2 10 The physical properties are as fo...

Embodiment 2

[0042] AgMgNi-SnO 2 In 2 o 3 12 Materials prepared as examples

[0043] 1. 19.98kg of Ag ingot, 0.01kg of Ni sheet, and 0.01kg of Mg ingot were smelted at 1200°C, then water atomized at 1150°C to make powder, and the water atomization pressure was 42MPa, and finally the powder passed through a 200-mesh sieve, Obtain AgMgNi alloy powder;

[0044] 2. 8.8kg of AgMgNi powder and 1.0kg of 4μm SnO 2 Powder, 0.2kg of 5μm In 2 o 3 Preparation of AgMgNi-SnO by powder mechanical dry mixing 2 In 2 o 3 12 powder;

[0045] 3. AgMgNi-SnO 2 In 2 o 3 12 powders were made into ingots under a pressure of 220 MPa on a cold isostatic press, and the diameter of the ingots was 86 mm.

[0046] 4. AgMgNi-SnO 2 In 2 o 312 ingots were sintered under vacuum for 4 hours at a sintering temperature of 860°C.

[0047] 5. AgMgNi-SnO 2 In 2 o 3 12 spindles are extruded at 820°C, and the extrusion specification is Φ6.

[0048] 6. AgMgNi-SnO 2 In 2 o 3 12. The wire is cold drawn to the r...

Embodiment 3

[0051] Taking the preparation of AgCuNi-ZnO10 material as an example

[0052] 1. 19.98kg of Ag ingots, 0.01kg of Cu rods, and 0.01kg of Ni sheets were melted at 1300°C, and then water atomized at 1250°C to make powder. The water atomization pressure was 60MPa, and the final powder passed 200 Mesh sieve, thereby obtain AgCuNi alloy powder;

[0053] 2. Mechanical dry mixing of 9kg of AgCuNi powder and 1kg of 7μm ZnO powder to prepare AgCuNi-ZnO10 powder;

[0054] 3. The AgCuNi-ZnO10 powder is made into an ingot under a pressure of 180 MPa on a cold isostatic press, and the diameter of the ingot is 83 mm.

[0055] 4. The AgCuNi-ZnO10 ingot was sintered under vacuum for 4 hours at a sintering temperature of 800°C.

[0056] 5. The AgCuNi-ZnO10 spindle is extruded at 780°C, and the extrusion specification is 40X4.

[0057] 6. The AgCuNi-ZnO10 strip is rolled and punched to the required specifications through a cold rolling mill.

[0058] The physical properties of the AgCuNi-ZnO...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com