Patents

Literature

33results about How to "Improve abrasiveness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

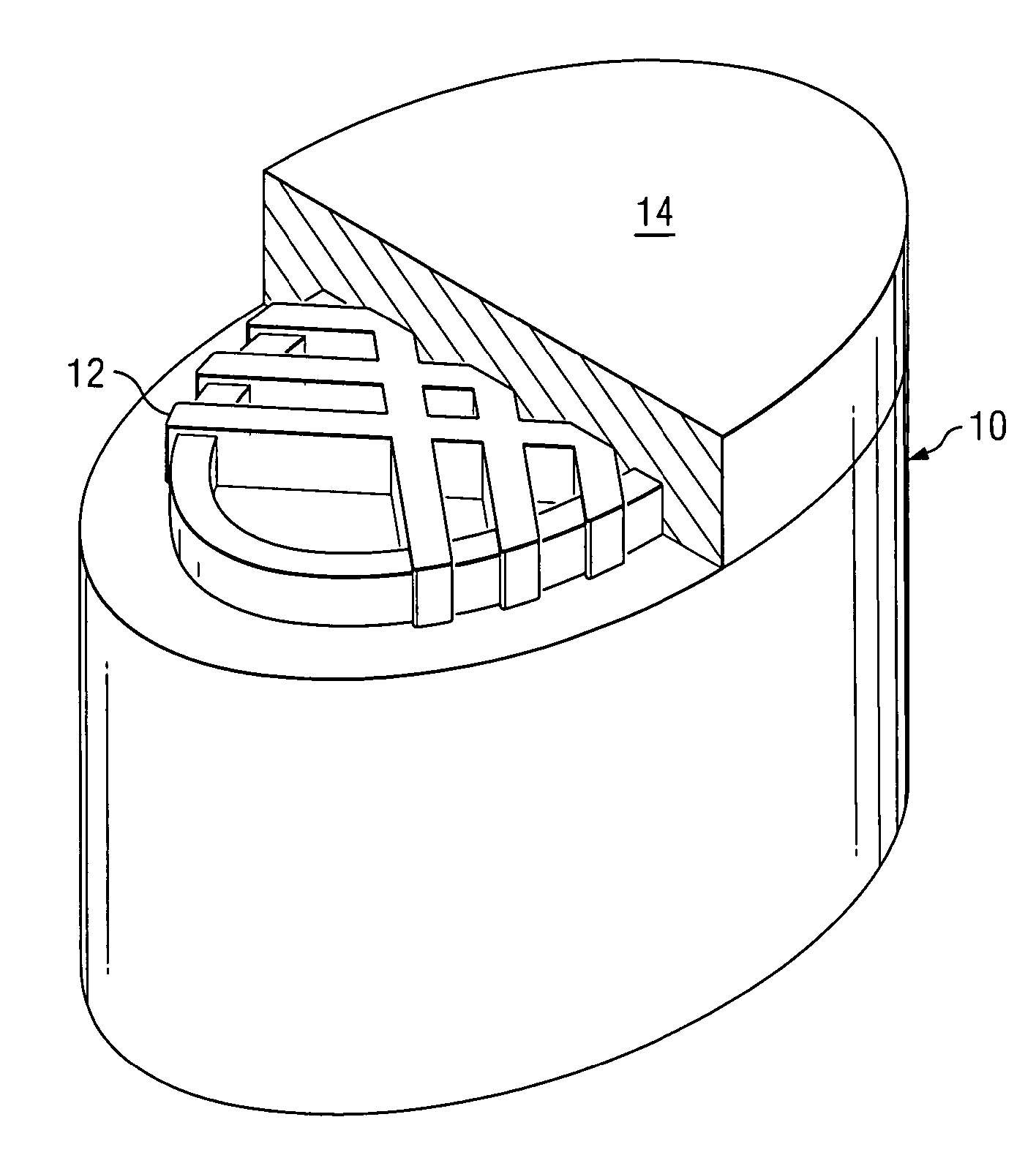

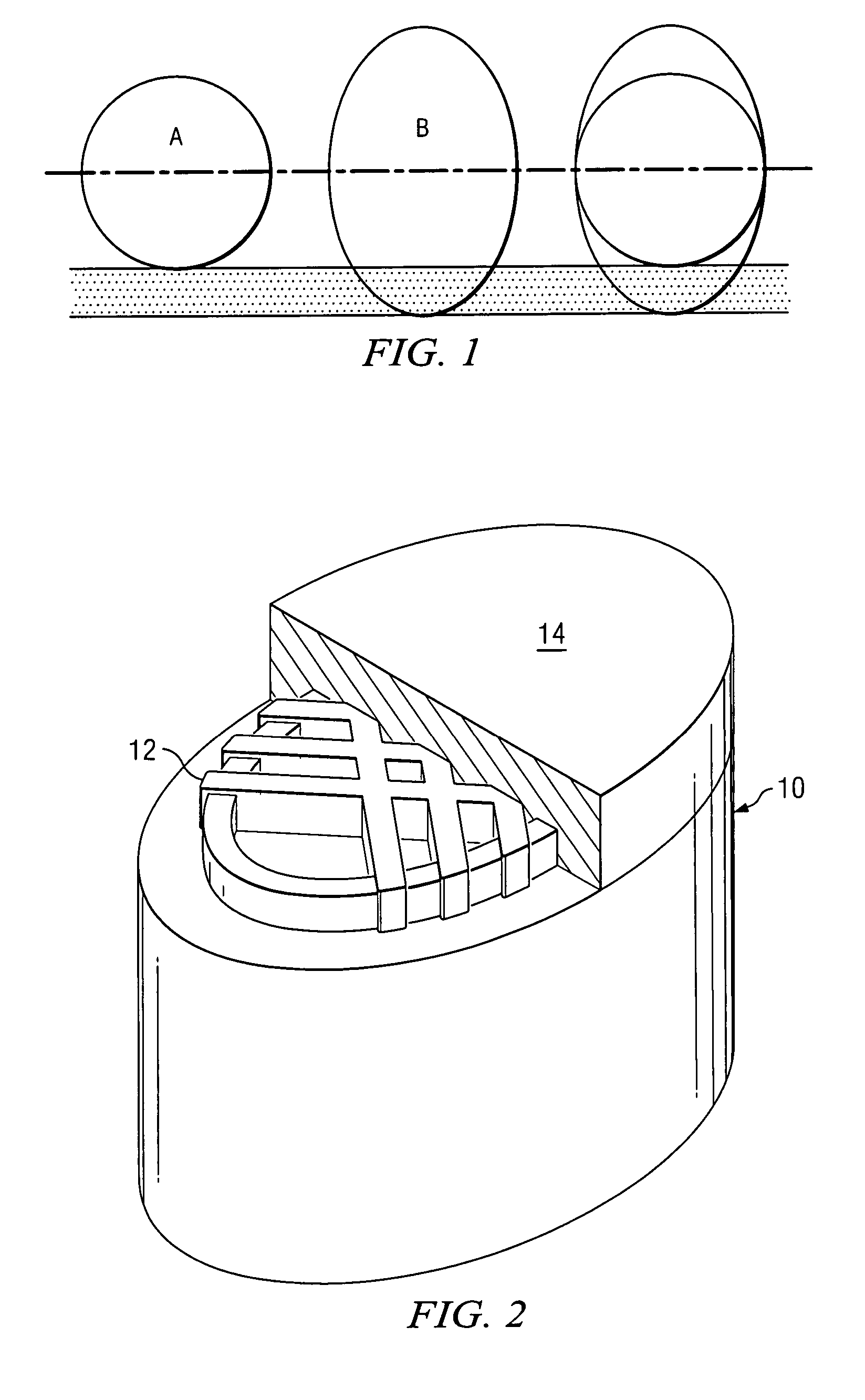

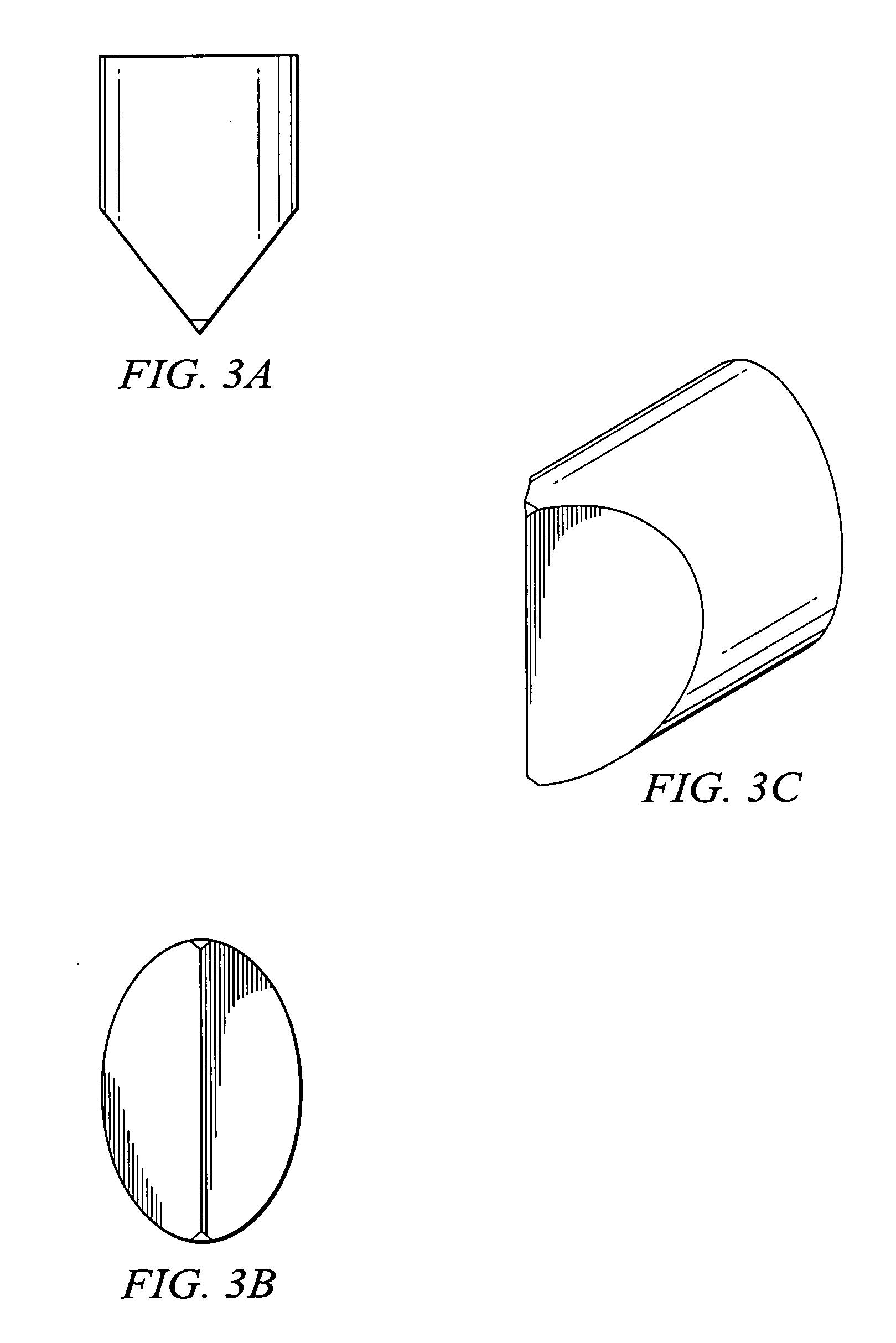

PDC cutter for high compressive strength and highly abrasive formations

InactiveUS20070235230A1Reduce wearReduce crackingDrill bitsConstructionsCompressive strengthUltimate tensile strength

A PDC cutter utilizes the combination of an elliptical shape with higher thermal resistance obtained through leaching to provide a cutter which is more effective than a cutter using either concept alone. The PDC cutter includes a tungsten carbide portion with protrusions extending from a surface thereof in a pattern. The diamond volume is mounted to the surface wherein the protrusions allow for the diamond volume to be larger about a perimeter edge of the cutter and smaller / shallower in a center region of the cutter. The protrusions providing surfaces for the diamond layer (table) to bond to the underlying tungsten carbide portion. With this configuration, diamond volume is maximized around the edge of the cutter.

Owner:VAREL INT IND

Composite combined aluminum oxide-silicon carbide-(carbon) system amorphous refractory material

The invention relates to a complex combination alumina-carborundum-(carbon) series amorphous fire proof material, and the formula comprises: 36 to 32 percent of 8-3mm corundum or bauxite, 18 to 26 percent of 3-1mm corundum or bauxite, 10 to 22 percent of 1-0.0088mm corundum or bauxite, 0 to 15 percent of 1-0.088mm carborundum, 0 to 3 percent of 1-0.0088 spherical asphalt, 0 to 20 percent of d90 less than 0.088mm corundum or bauxite, 0 to 20 percent of d90 less than 0.088 carborundum, 0 to 3 percent of d90 less than 0.088mm high-carbon materials, 0 to 5 percent of alpha alumina micro powder, 1 to 8 percent of alumina hydrate, 1 to 6 percent of silicon ash, 0 to 2 percent of calcium aluminate cement, 0.05 to 0.4 percent of plus super-plasticizer (polycarboxylic acids+sulfonated naphthalene formaldehyde polymer+sulfonated melamine polymer), 1 to 6 percent of plus polypropylene acid series latex and 1 to 6 percent of plus water. Compared with low-cement aluminum carborundum carbon material, the material has good anti-corrosion performance. Therefore, the service life of a kilneye of a cement kiln and a main groove slag line of a blast furnace can be prolonged when a product is combined by the complex combination alumina-carborundum-(carbon) series amorphous fire proof material instead of the cement.

Owner:RUITAI MATERIALS TECHNOLOGY CO LTD

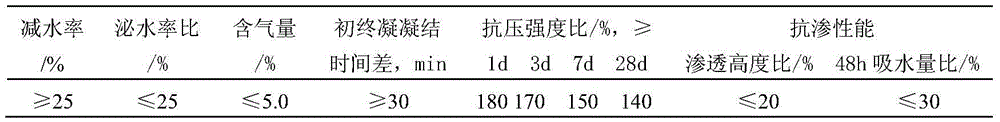

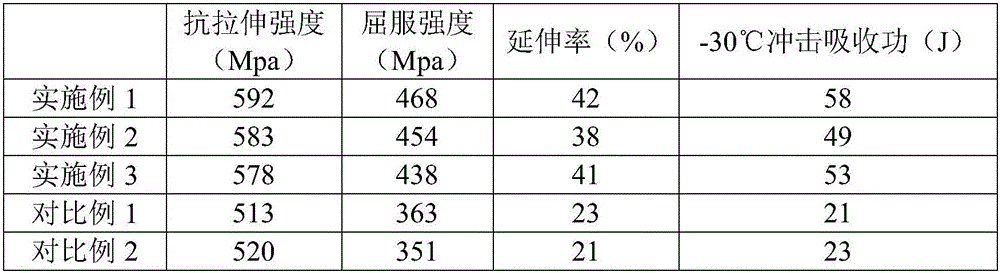

Marine concrete based on combined functional type additive

The invention discloses marine concrete based on a combined functional type additive. The marine concrete overcomes the defects that existing concrete is poor in durability and corrosion resistance. The marine concrete comprises the following raw materials by weight part of 100 parts of hot cement, 25-30 parts of I-level coal ash, 25-30 parts of granulated blast furnace slag, 0.5-1.5 parts of an anti-crack anti-corrosion plasticizer, 250-280 parts of medium-coarse sand, 360-400 parts of secondary rubble and 50-60 parts of water in a mixing mode. The anti-crack anti-corrosion plasticizer comprises the following components by weight percentage of 20-30% of a shrinking and reducing plasticizer, 5-15% of acid and a material capable of generating acid, 1-6% of a corrosion resisting agent, 0.1-1% of a catalyst, 1-3% of a neutralizing agent, 0.1-0.3% of a water repellent, 5-40% of a micro-expanding agent, 0.05-0.5% of an air entraining agent, 1-5% of a compacting agent and 15-55% of a carrier. The strength, the durability, the chloridion permeability resistance and the chloridion diffusion coefficient of the marine concrete are all enhanced.

Owner:中电建路桥集团有限公司

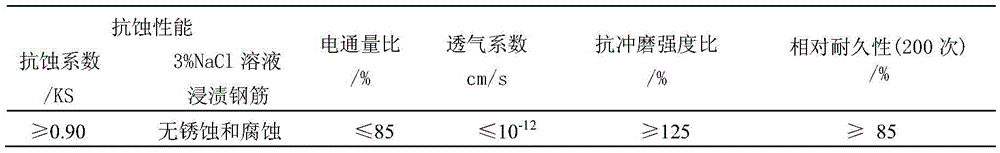

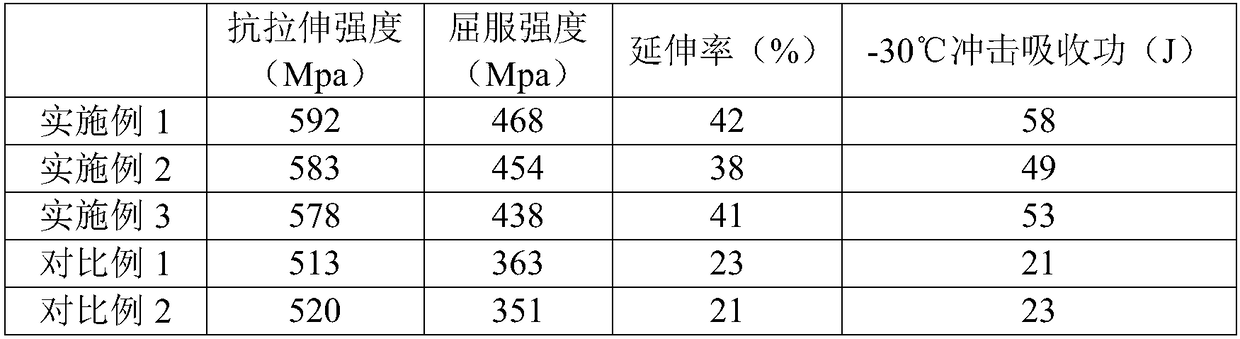

Welding method for 12Cr5Mo martensite stainless steel

ActiveCN106312242AEliminate heat treatmentEasy to install on siteArc welding apparatusWelding/cutting media/materialsSlagManganese

The invention relates to a welding method for 12Cr5Mo martensite stainless steel. The welding method comprises the following steps: step I, preparing a 12Cr5Mo martensite stainless steel groove, carrying out butt-joint assembly on the groove, and pre-heating a welded part of the groove at a pre-heating temperature being 100-150 DEG C; and step II, separately carrying out a primary welding process, a secondary welding process and a tertiary welding process on the welded part of the groove by use of a welding rod, wherein the welding rod is composed of a welding core and a coating; and the welding core consists of the following raw materials: C, Ni, Cr, Mn, Si, Ti, Nb, V, Ta, Zr, La, Ce, Pr, W, N and Fe. The coating consist of the following components: rutile, titanium dioxide, potassium feldspar, mica, calcium carbonate, nitrogen containing ferrochromium, electrolytic manganese, metal nickel, ferrocolumbium, magnesium oxide, yttrium oxide, sodium fluosilicate, hydroxypropyl methyl cellulose, phenolic resin and melamine. According to the welding method, a welding process is simple, welding seam molding is beautiful, slag is easily separated and deposition efficiency is high; and the obtained welding seam metal has excellent mechanical performance and mechanical property.

Owner:THE SIXTH CONSTR CO LTD OF CHINA NAT CHEM ENG

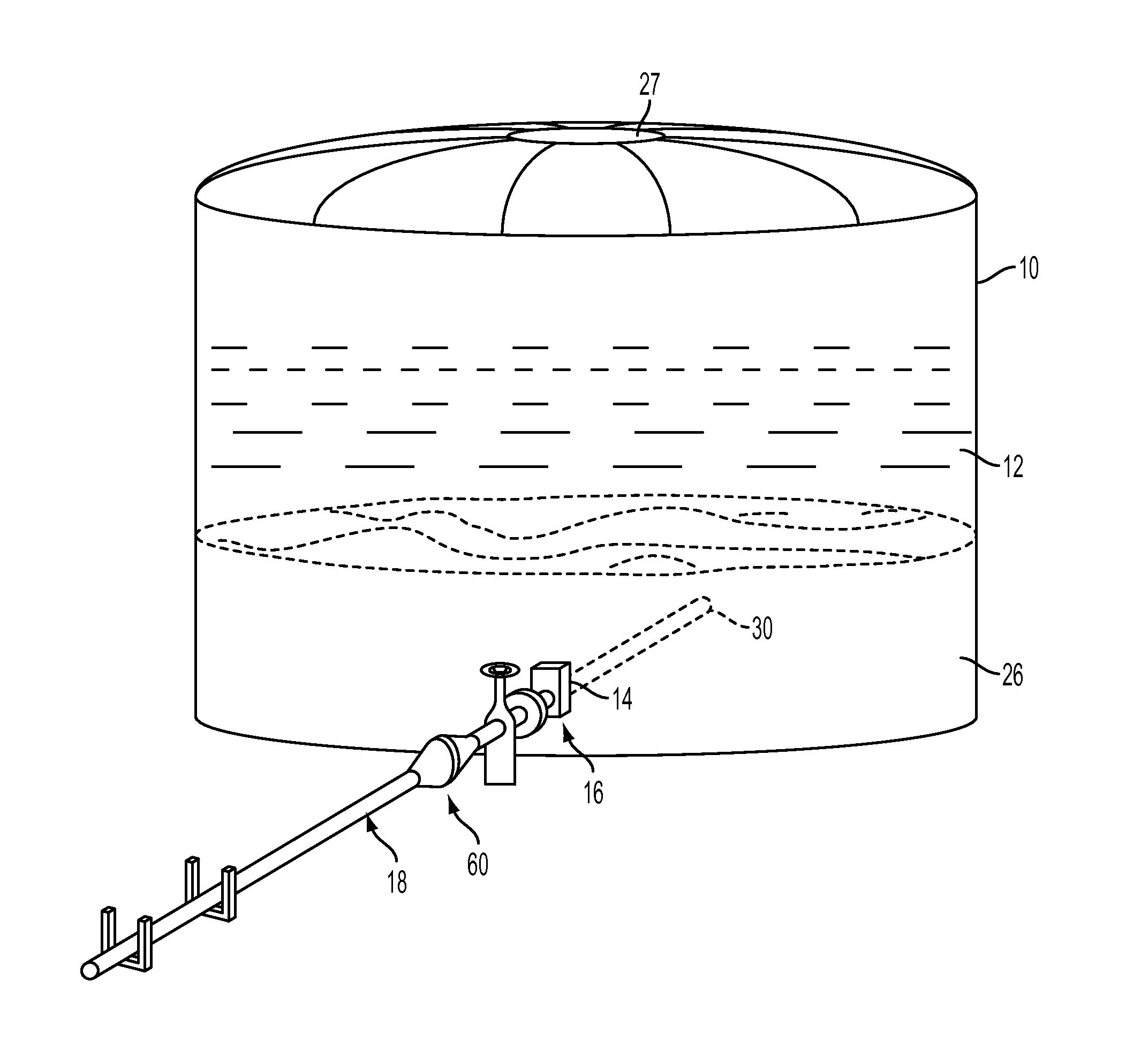

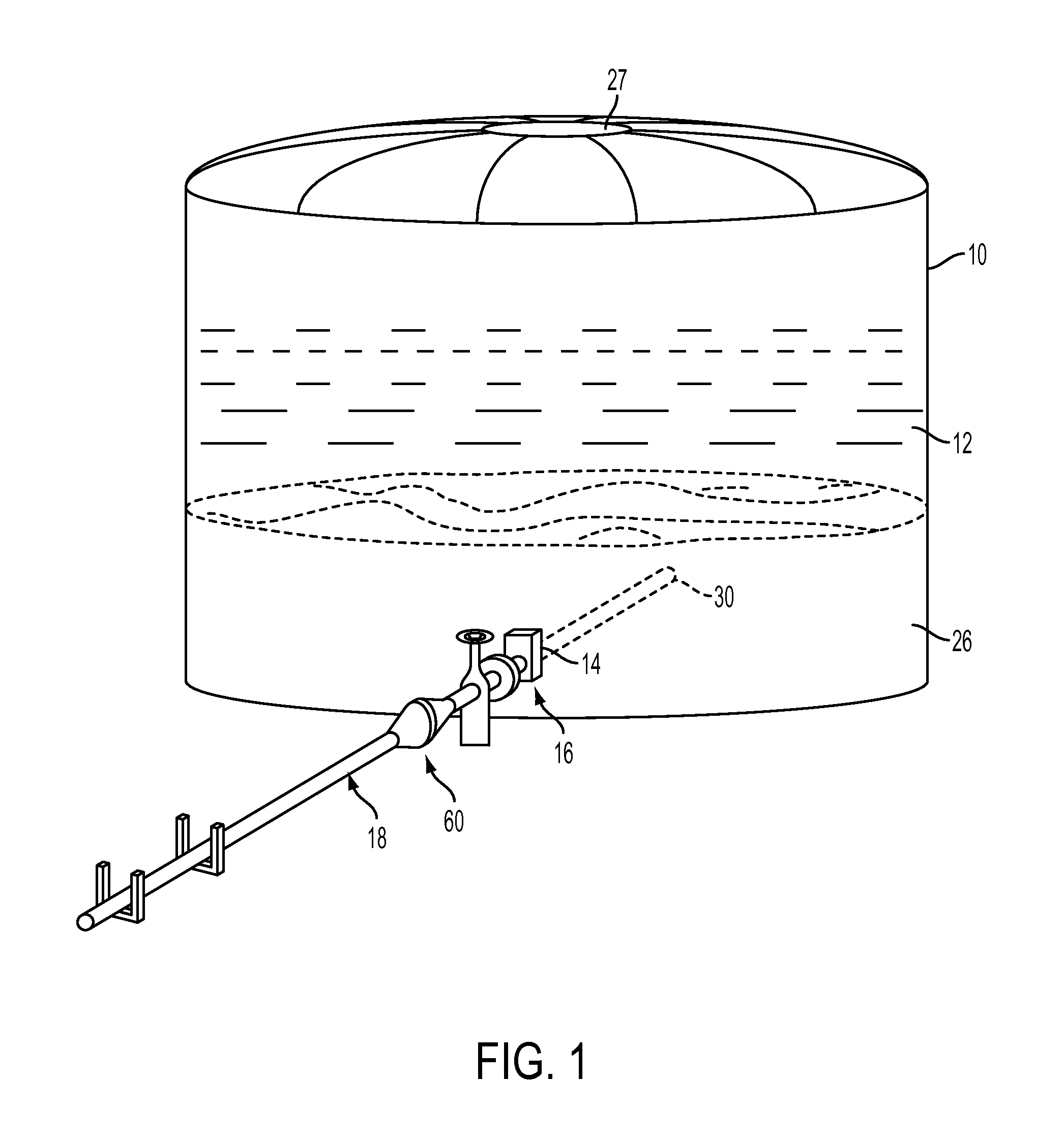

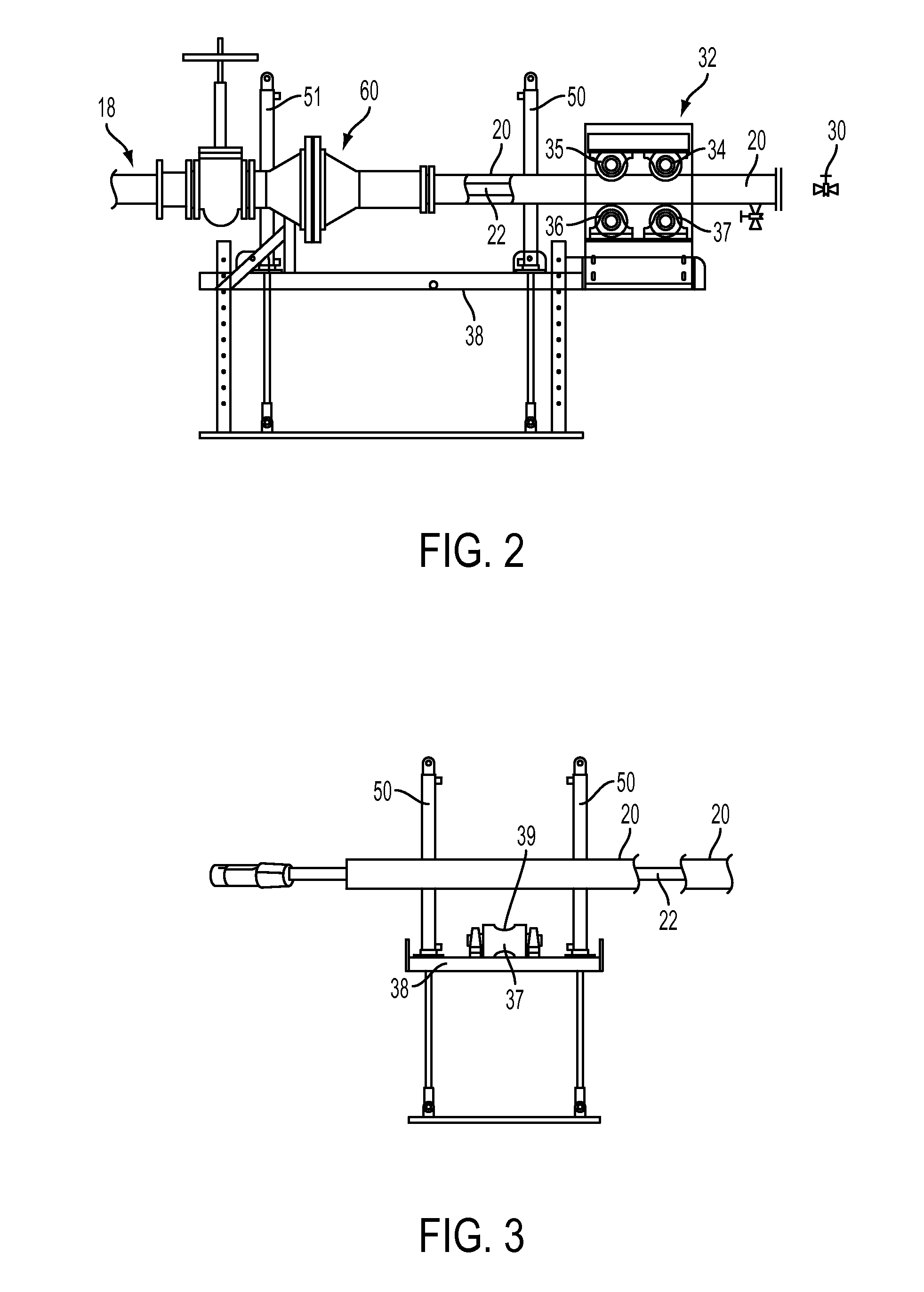

System and method for removing sludge from a storage tank

InactiveUS20140190517A1Improve abrasivenessDifficult to fluidizeHollow article cleaningSedimentation separationVertical planeSludge

The system and method permits the use of equipment that is located exterior to a container, such as a tank container liquid hydrocarbon material within which a sludge deposit has accumulated, and then inserted, as through an access opening in the side of the tank. In addition to other innovations, an improved hydraulic equipment positioning arrangement is provided, for both positioning, inserting and withdrawing the conduit structure and end effectors for accessing the sludge or sediment, which may include a leveling element preferably in the form of an hydraulic system that operates to move the assembly in a vertical plane as well as a rotary driven hydraulic system for driving the conduit structure along a long axis.

Owner:TRADEBE ENVIRONMENTAL SERVICES

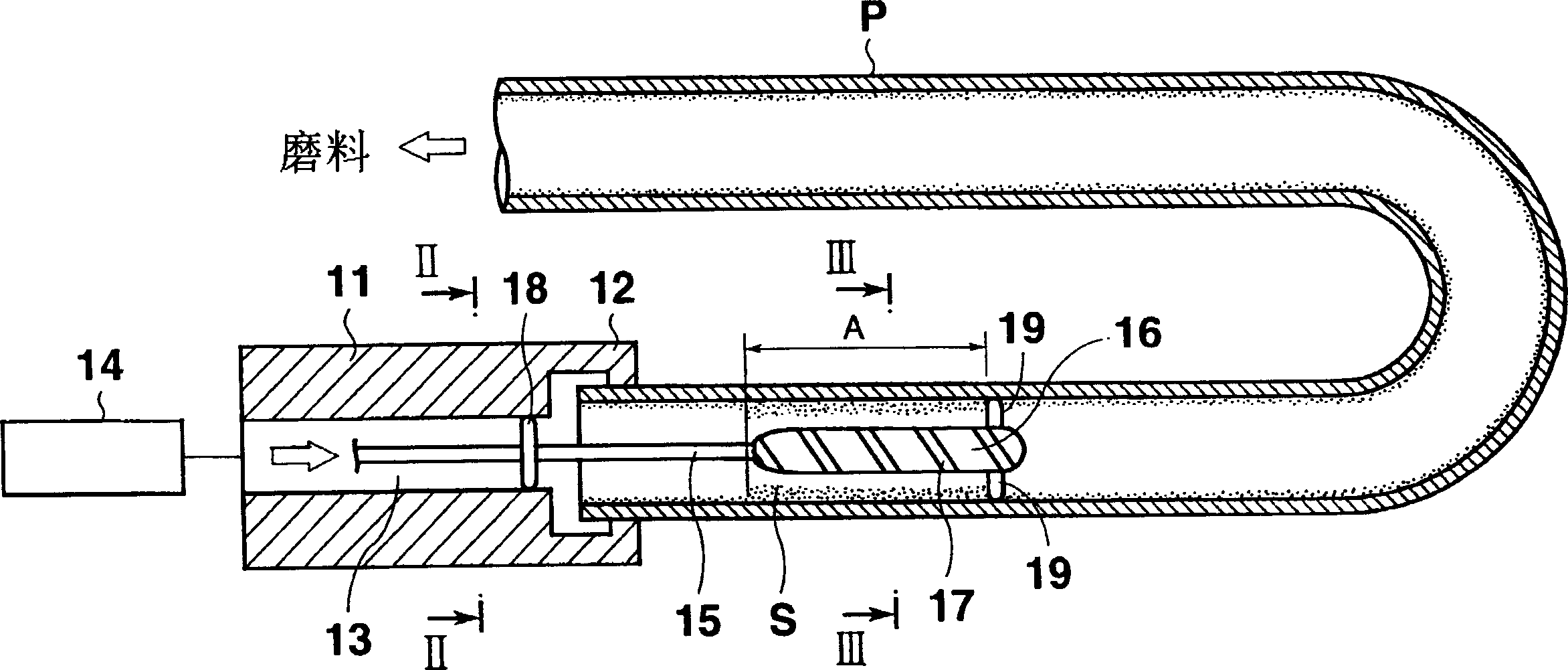

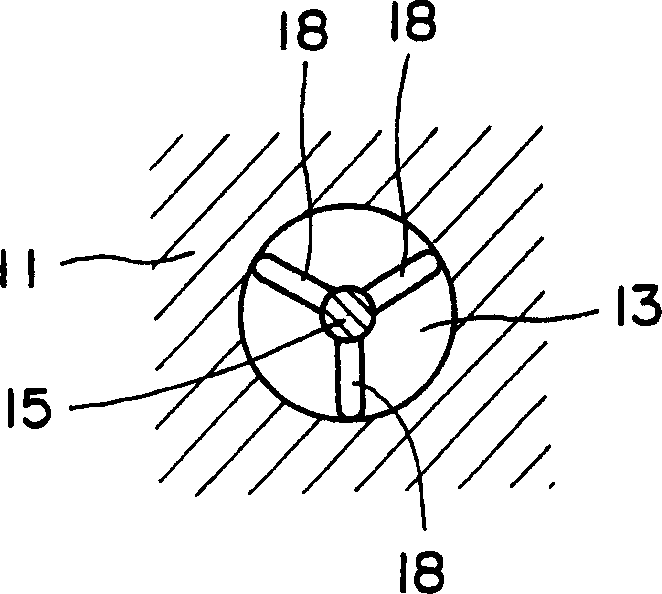

Foreign matter removnig device and method

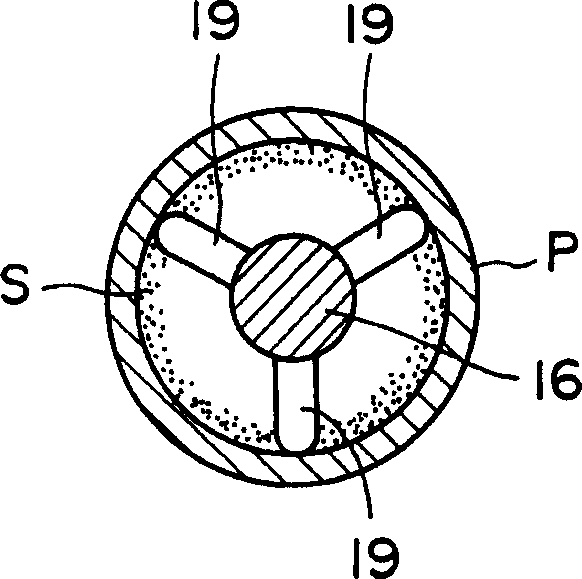

InactiveCN1471451AIncrease centrifugal forceAbrasive smoothHollow article cleaningAbrasive blasting machinesForeign matterEngineering

The present invention is one for providing an apparatus and a method which make it possible to remove a foreign object or matter such as scale attached on an inner surface of a pipe easily for a short period of time by means of simple equipment and manner, and constituted as follows. Specifically, a holder (11) is attached onto an end of a pipe (P), an abrasion assisting member (16) fixed to a tip end of a support arm (15) is inserted into the pipe (P) by use of the holder (11) and stopped at an area (A) where oxide scale (S) is generated in a large amount. Then abrasive is sent with pressure into the pipe (P) by a blast device (14), and thus a flow rate of the abrasive in the scale-abraded area (A) is increased to abrade and remove the oxide scale (S) securely. Moreover, if required, a spiral groove (17) is formed on an outer circumference of the abrasion assisting member (16) to increase centrifugal force of the abrasive.

Owner:MITSUBISHI HEAVY IND LTD

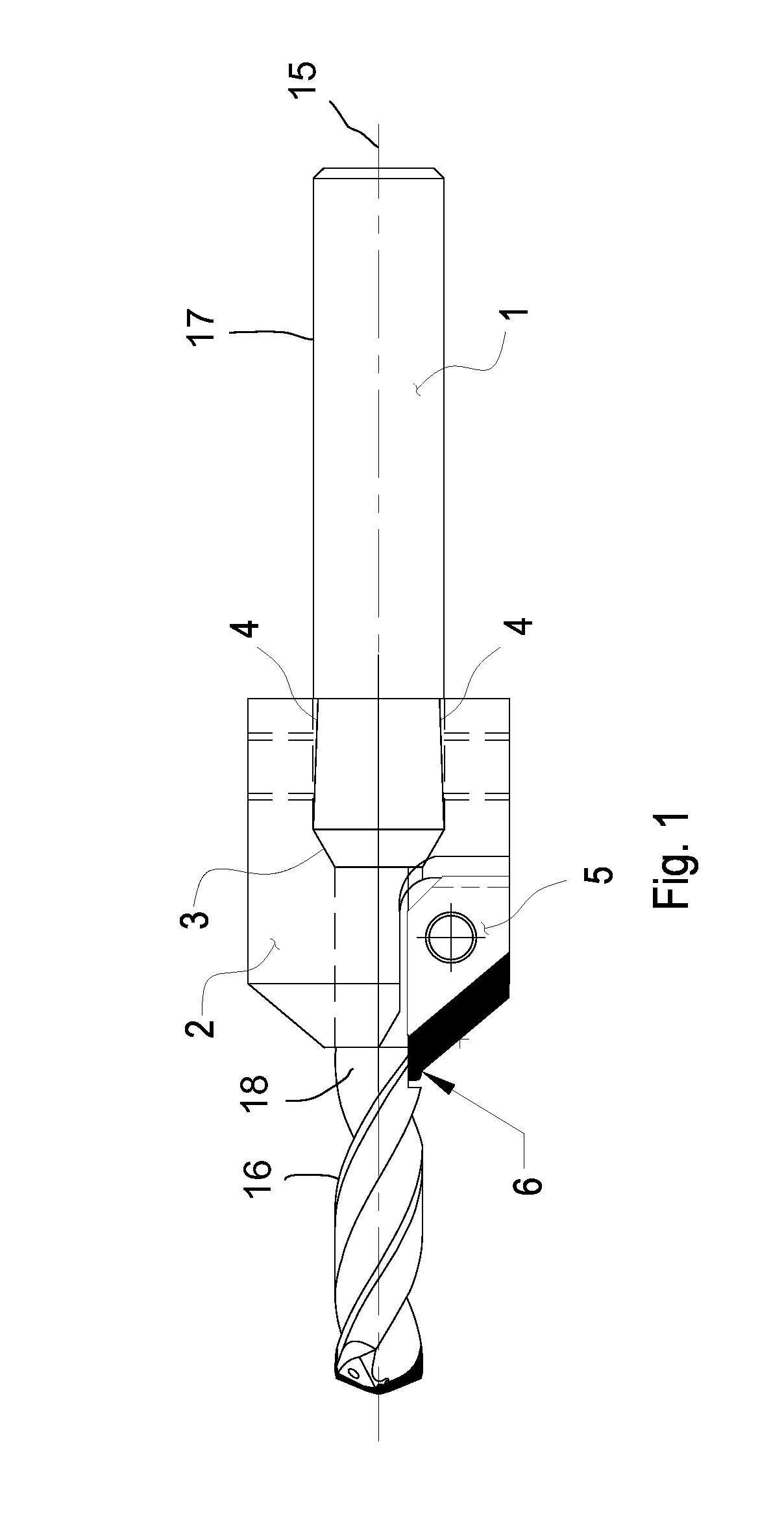

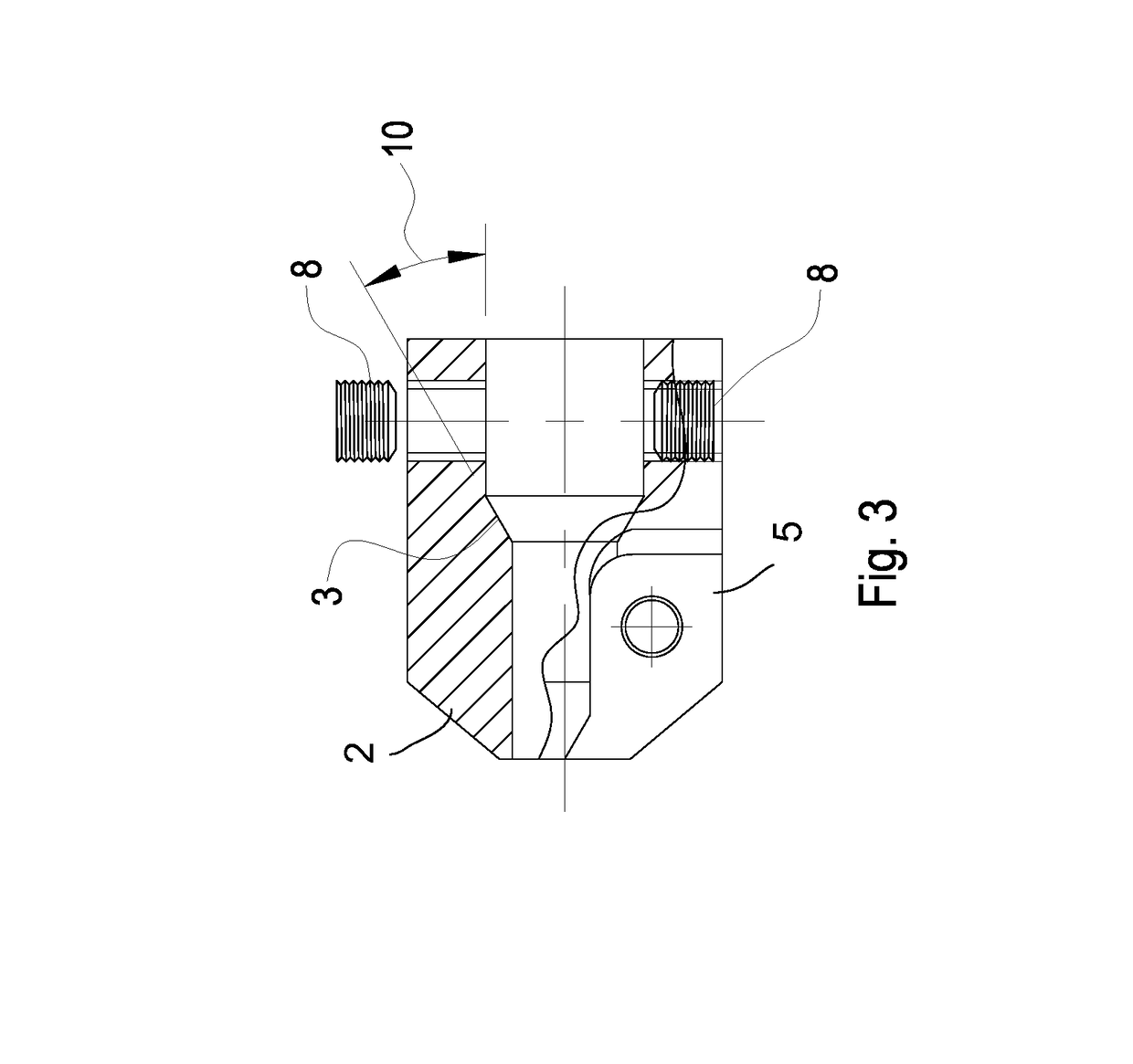

Modular precision drill countersink assembly

ActiveUS8469642B1Good precisionImprove matchThread cutting toolsWood turning toolsEngineeringDrill bit

A modular countersink assembly, comprising a drill having an exterior tapered surface, a countersink body having an interior tapered surface for mating with the exterior tapered surface of the drill, and an insert removably secured to the countersink body enables an operator to replace either the drill and / or the insert if one or the other or both become worn. The insert is positioned both axially and radially and may have a PCD cutting edge.

Owner:PRECORP INC

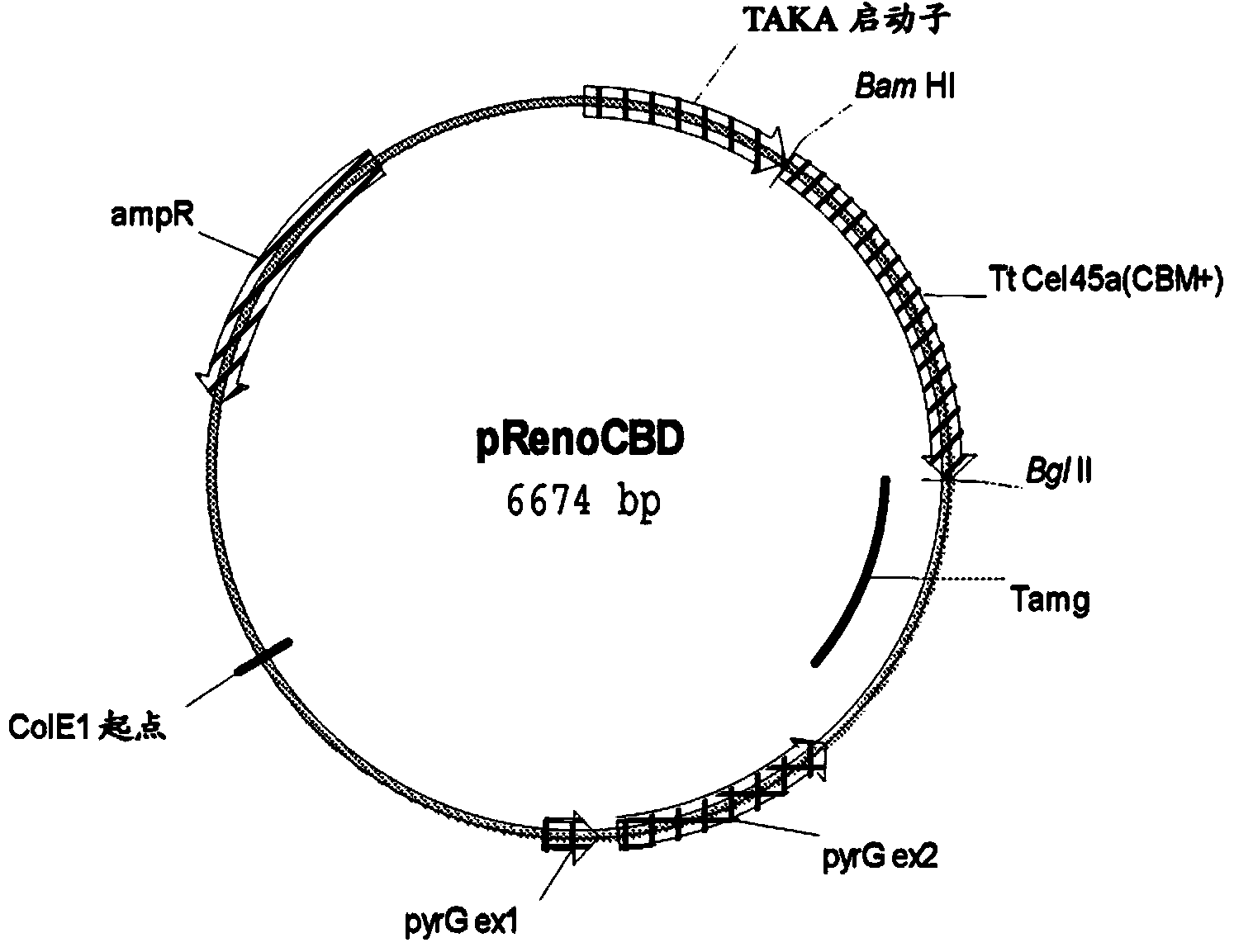

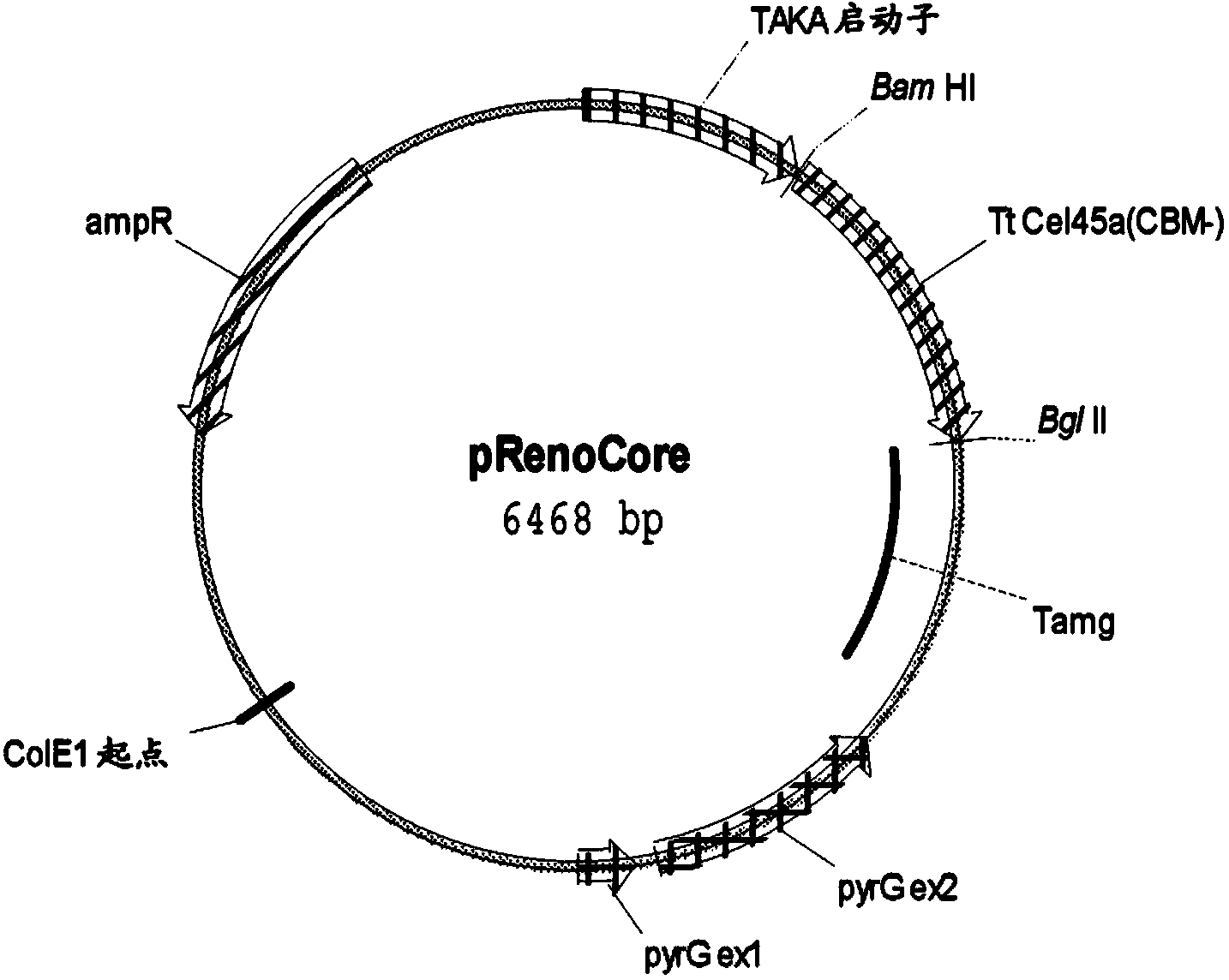

Method for treating textile with endoglucanase

InactiveCN103429736ASave energyNo weight lossBiochemical fibre treatmentDetergent compounding agentsEngineeringEndoglucanase activity

The present invention relates to the method for manufacturing textile, by treating textile with an isolated polypeptide having endoglucanase activity, especially in biostoning and bio- polishing process.

Owner:NOVOZYMES AS

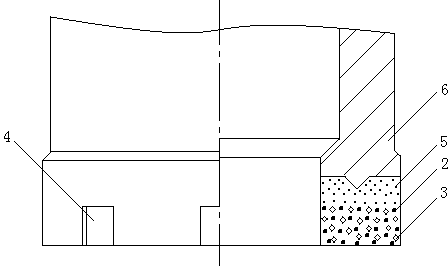

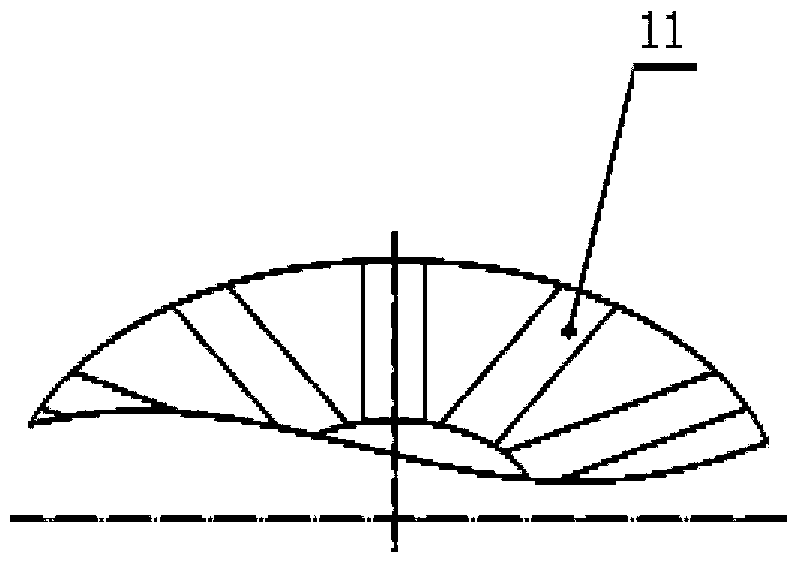

Fabrication method for hot pressing diamond bit with added aluminium oxide hollow balls

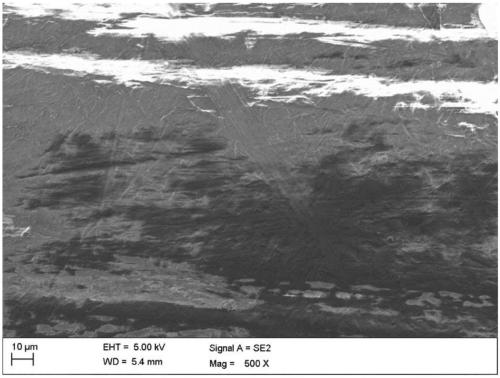

InactiveCN103015903AManufacturing Method AdvantagesEnhance the edge effectDrill bitsAdhesiveGraphite

The invention relates to a fabrication method for a hot pressing diamond bit with added aluminium oxide hollow balls. The method comprises the following processes: allowing the aluminium oxide hollow balls and the diamonds to be subjected to pelletization and film applying; uniformly mixing the film applied aluminium oxide hollow balls, the diamonds and bit matrix powder subjected to ball milling and an adhesive; weighing the mixture and filling into a graphite die according to the required amount of each of drill bits in various specifications; pressing a drill bit steel basal body on the graphite die which is then delivered into an mid-frequency electric furnace and pressing machine all-in-one machine for sintering, wherein the hot pressing pressure is 15-16 MPa, the boiler temperature is 950-960 DEG C, the heat-insulating time is 4-5 min, and the discharging temperature is 815-830 DEG C; and after discharging, slowly cooling to the ambient temperature under the heat-insulating condition, and carrying out demoulding so as to fabricate the drill bit provided by the invention. According to the invention, the diamond volume concentration of the diamonds in a fan-shaped cutting operating block of the drill bit is 11-13 percent, and the volume concentration of the aluminium oxide hollow balls is 12-18 percent. The drill bit is used for drilling objects that are as hard as that of hard and compact rocks; and average drilling effectiveness is improved by 95 percent, and the service life is improved by 80 percent as compared with a general diamond bit.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

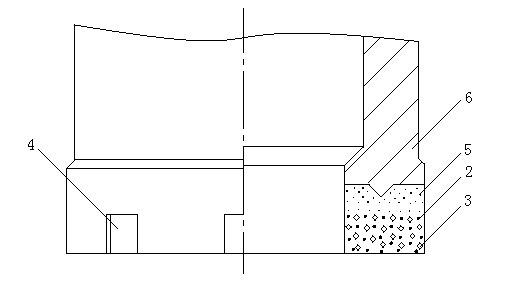

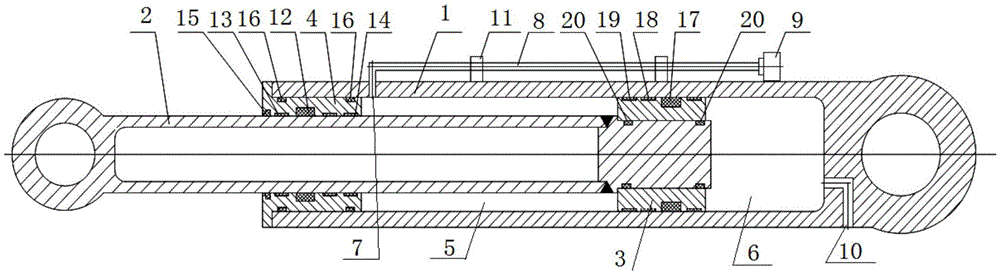

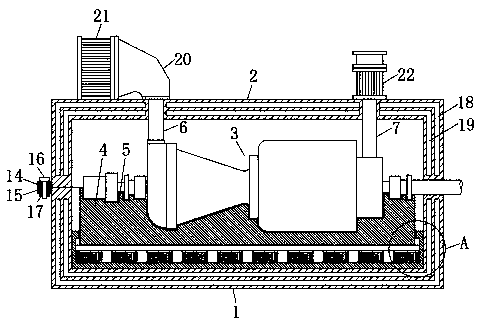

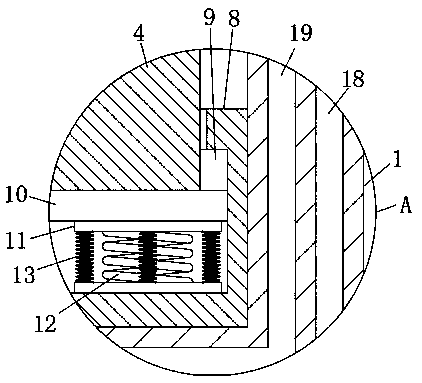

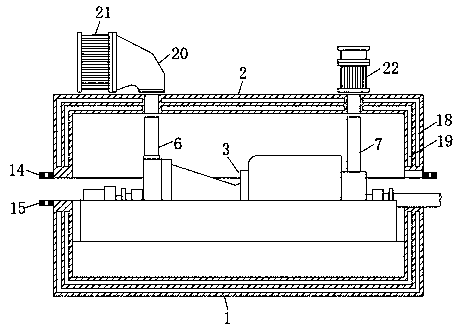

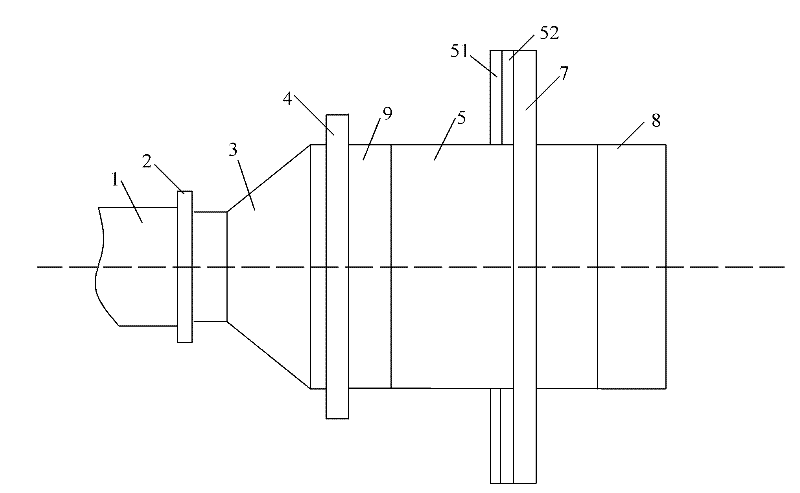

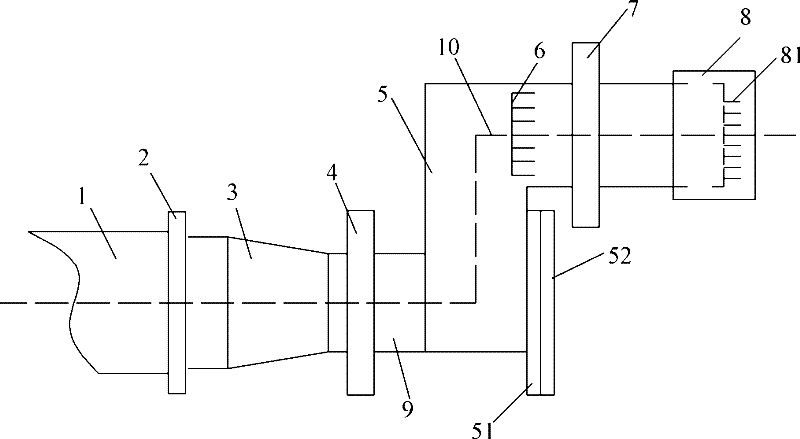

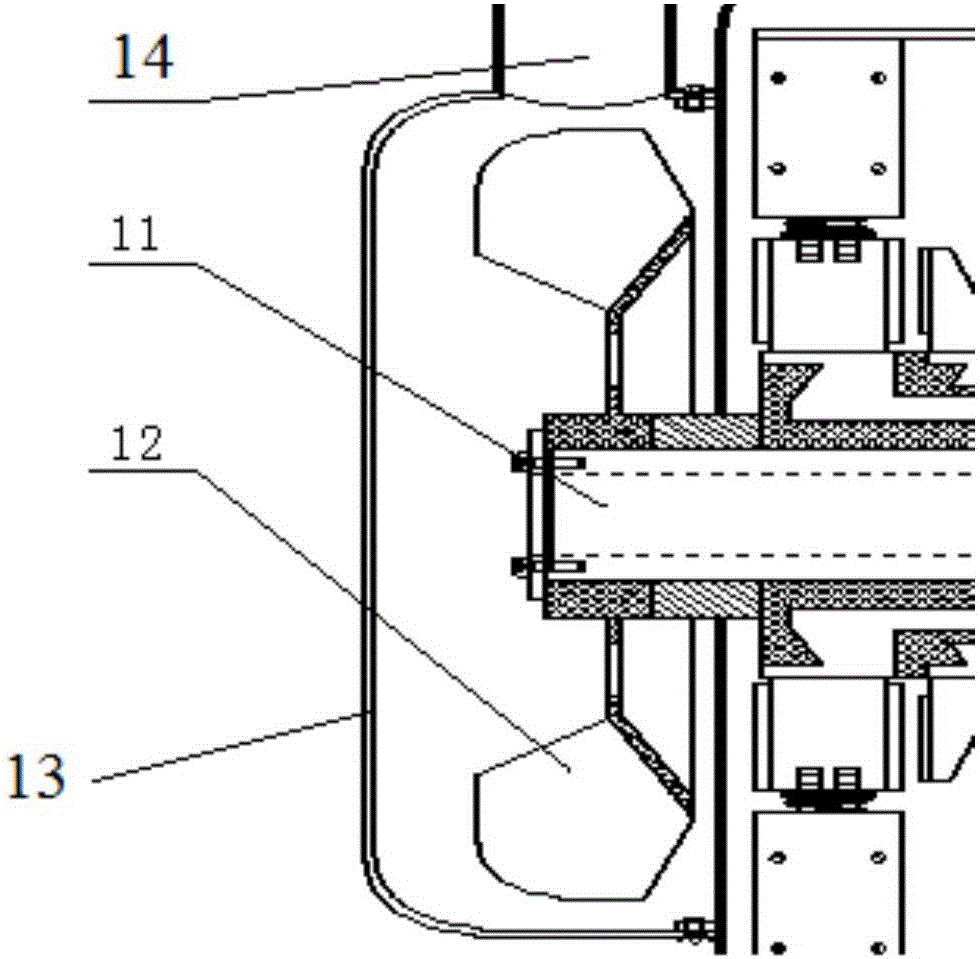

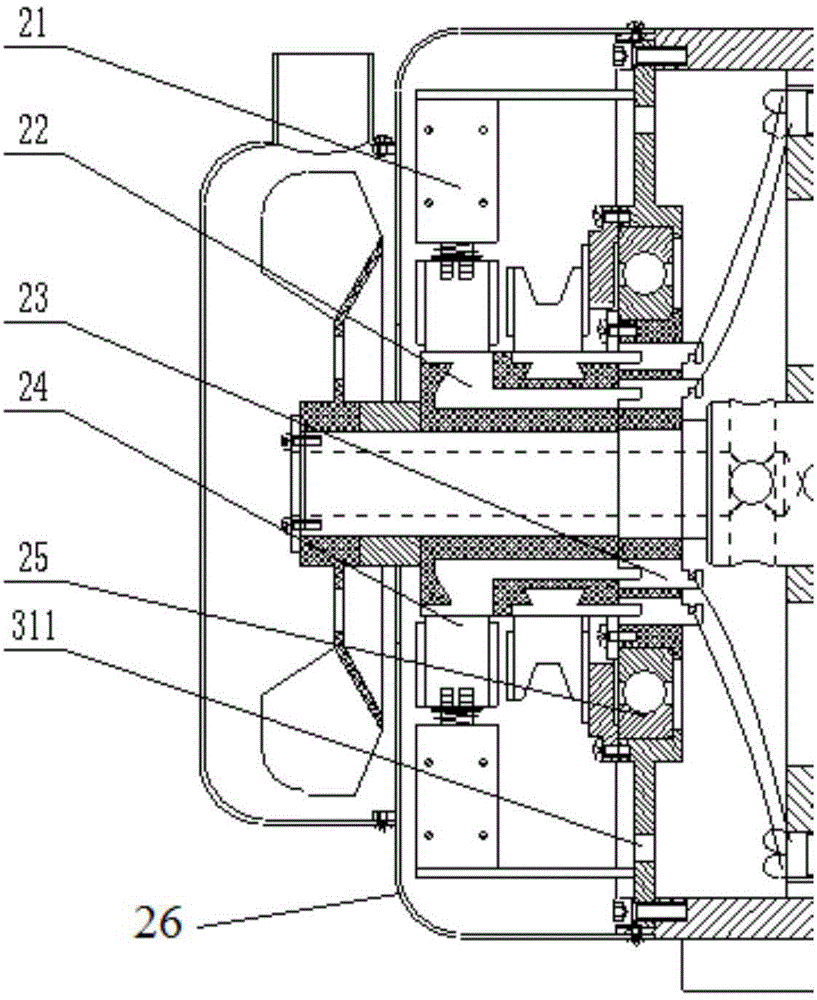

Anti-abrasion oil-air cylinder and engineering machine

InactiveCN105090161AAvoid bulkImprove abrasivenessFluid-pressure actuatorsParticulatesPulp and paper industry

The invention relates to an anti-abrasion oil-air cylinder and an engineering machine. The anti-abrasion oil-air cylinder comprises a cylinder barrel, a piston rod, a piston and a guide sleeve. The guide sleeve is arranged at the end of the cylinder barrel, and the piston is arranged in the cylinder barrel; one end of the piston rod is connected to the piston, and the other end of the piston rod penetrates out of the guide sleeve; one side of the piston is provided with an air cavity, and the other side of the piston is provided with an oil cavity; an air inlet is formed in the portion, provided with the air cavity, of the cylinder barrel, the air inlet is connected with one end of an air pipe, and the other end of the air pipe is connected to a filter; and the filter is fixedly arranged on the cylinder barrel, and an oil inlet is formed in the portion, provided with the oil cylinder, of the cylinder barrel. According to the anti-abrasion oil-air cylinder and the engineering machine, the filter is arranged on the cylinder barrel, the problem that due to the fact that the filter is independently arranged, the size of the oil-air cylinder is overlarge can be solved, the filter can remove particulate impurities in the air and provide clean air for the air cavity, and the probability that due to the fact that the oil-air cylinder sucks the air with impurity particles in the working process, the abrasion is increased can be avoided.

Owner:XUZHOU HEAVY MASCH CO LTD

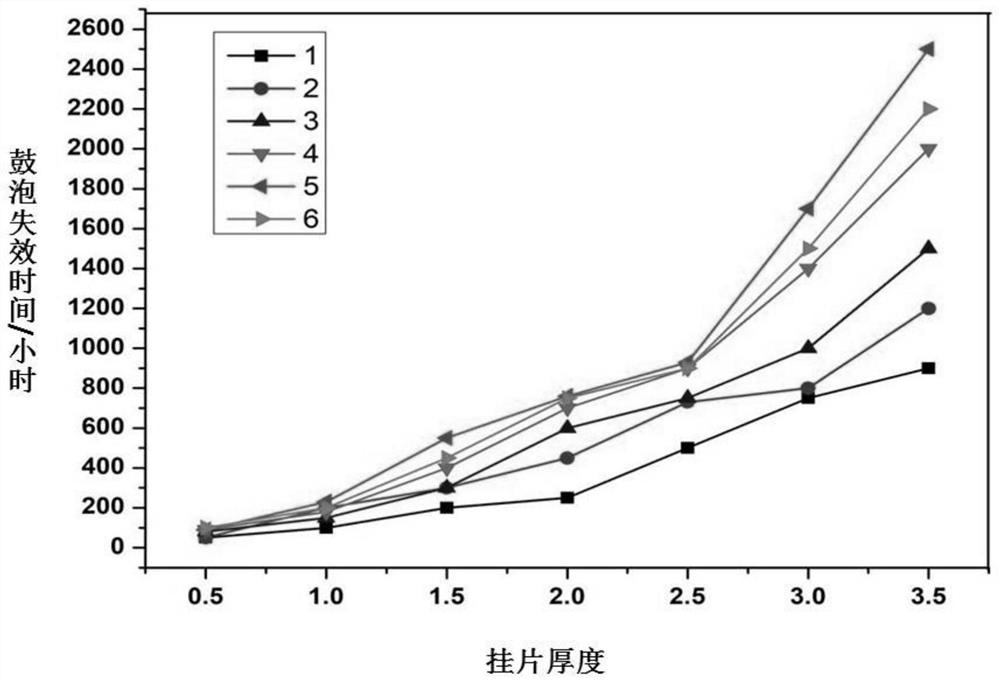

Graphene polymer energy-saving environment-friendly composite coating as well as preparation technology and application thereof

ActiveCN105623469AImprove thermal shock resistanceExcellent resistance to media penetrationFireproof paintsAnti-corrosive paintsNano siliconPolymer composites

The invention provides a graphene polymer composite organic coating which is mainly prepared from the following components in parts by weight: 40-60 parts of base resin, 1-1.5 parts of graphene, 30-55 parts of composite modifier and 20-45 parts of curing agent, wherein the base resin comprises phenol-formaldehyde resin and bisphenol F in a weight ratio of (1:2)-(1:4). The invention also provides a preparation method of the composite organic coating. The preparation method comprises the following steps: heating the phenol-formaldehyde resin, stirring and adding the bisphenol F resin; adding an antifoaming agent; adding graphene, stirring and dropwise adding a pretreating agent; adding polytetrafluoroethylene powder, silicon dioxide hollow spheres, mica powder, talc powder, a leveling agent and nano silicon; adding an ultraviolet absorbent and an antioxidant while keeping the system temperature below 60 DEG C to obtain modified resin; and mixing the modified resin with the curing agent and stirring to obtain the composite organic coating. The invention also provides an application of the organic coating.

Owner:田路兵

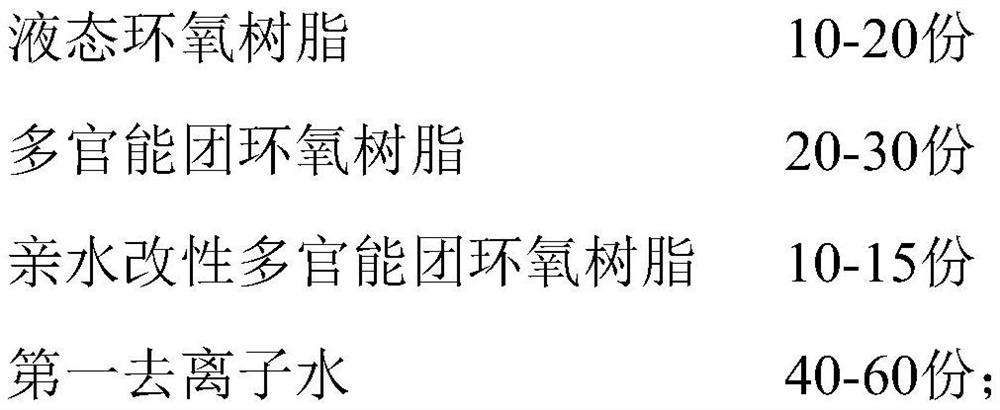

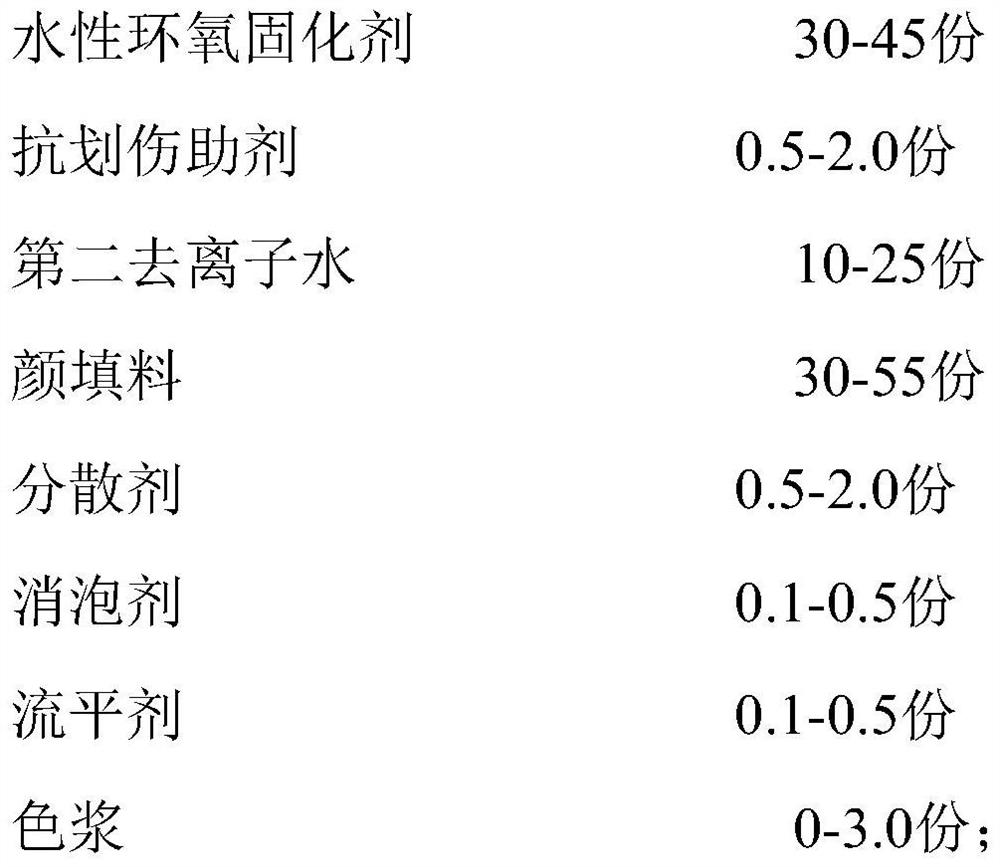

High-gloss high-hardness water-based epoxy floor coating and preparation method thereof

InactiveCN111763458AImprove the level ofReduce pollutionEpoxy resin coatingsPolymer scienceShrinkage rate

The invention belongs to the technical field of coatings and relates to a high-gloss high-hardness water-based epoxy floor coating and a preparation method thereof. The coating comprises a component Aand a component B. The component A is a water-based emulsion prepared from liquid epoxy resin, polyfunctional epoxy resin, hydrophilic modified polyfunctional epoxy resin and first deionized water; the component B is prepared from a water-based epoxy curing agent, second deionized water, a pigment filler, a dispersing agent, an antifoaming agent, a leveling agent, a scratch-resistant auxiliary agent and color paste. By compounding the modified polyfunctional epoxy resin, the scratch-resistant assistant and the pigment filler, the prepared floor coating has the advantages of favorable levelingproperty, high curing speed, high film crosslinking density, high bonding strength, low shrinkage rate during hardening and low tendency to flooding during construction. When coating film formation is performed, the hardness and gloss of a coating layer are high; the whole coating layer is seamless and flat, not prone to cracking and easy to clean; the probability of bubbles appearing on a water-resistant surface is low; and the environmental protection requirements are met.

Owner:英德市黑马涂料有限公司

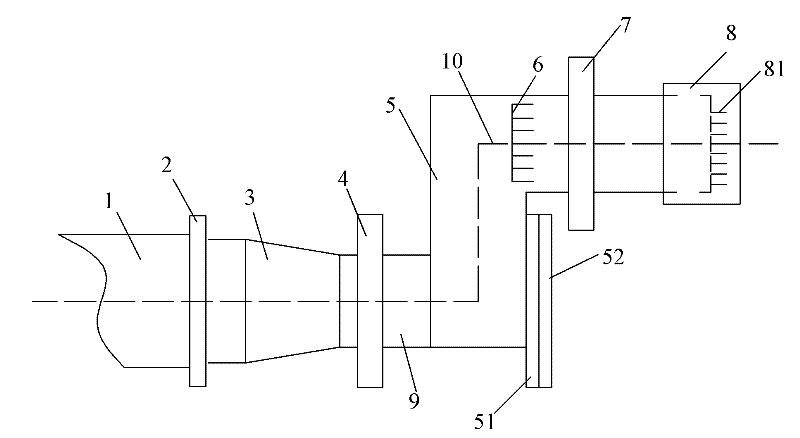

High-efficiency positive-pressure gas turbine

InactiveCN110094265AReduced assembly effortReduce the difficulty of assemblyGas turbine plantsTurbine/propulsion air intakesShock preventionGas turbines

The invention discloses a high-efficiency positive-pressure gas turbine. The high-efficiency positive-pressure gas turbine comprises a gas turbine body which is arranged in a lower case body and an upper case body. A mounting base is arranged at the lower end of the gas turbine body. According to the high-efficiency positive-pressure gas turbine, the gas turbine body is mounted in a mounting groove in the mounting base, so that mounting and fixing are convenient and firm; and the gas turbine body is arranged in the upper case body and the lower case body, so that the gas turbine body is well protected, and the working reliability is improved; a damping base is arranged so that the gas turbine body can be well damped and supported; a gas inlet silencing mechanism and a gas outlet silencingmechanism are arranged, and a first sound insulation layer and a second sound insulation layer are arranged in the upper case body and the lower case body, so that pneumatic noise and mechanical noisegenerated when the gas turbine body works are effectively lowered; and overall structure is beneficial to heat insulation, sound insulation and shock prevention, so that the working environment is improved, the working comfort of workers is improved, and the working efficiency is improved.

Owner:JIANGSU MARITIME INST

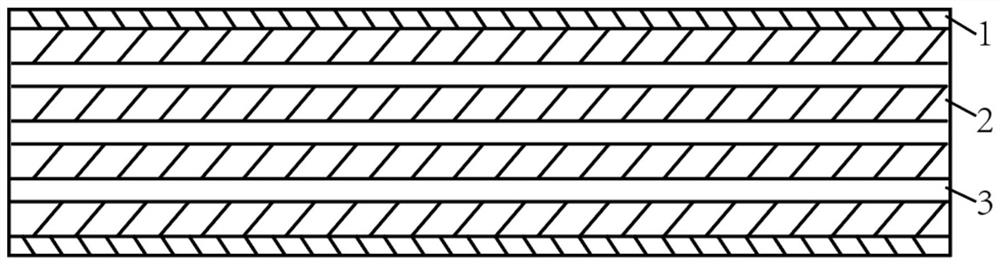

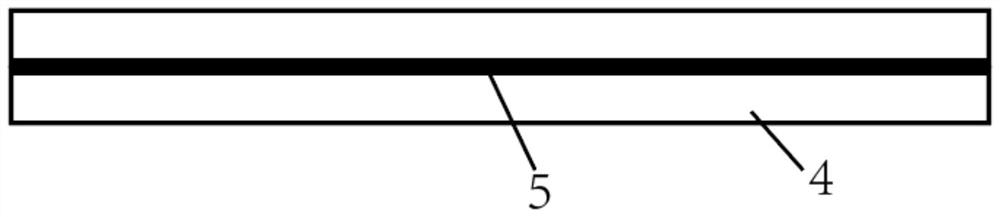

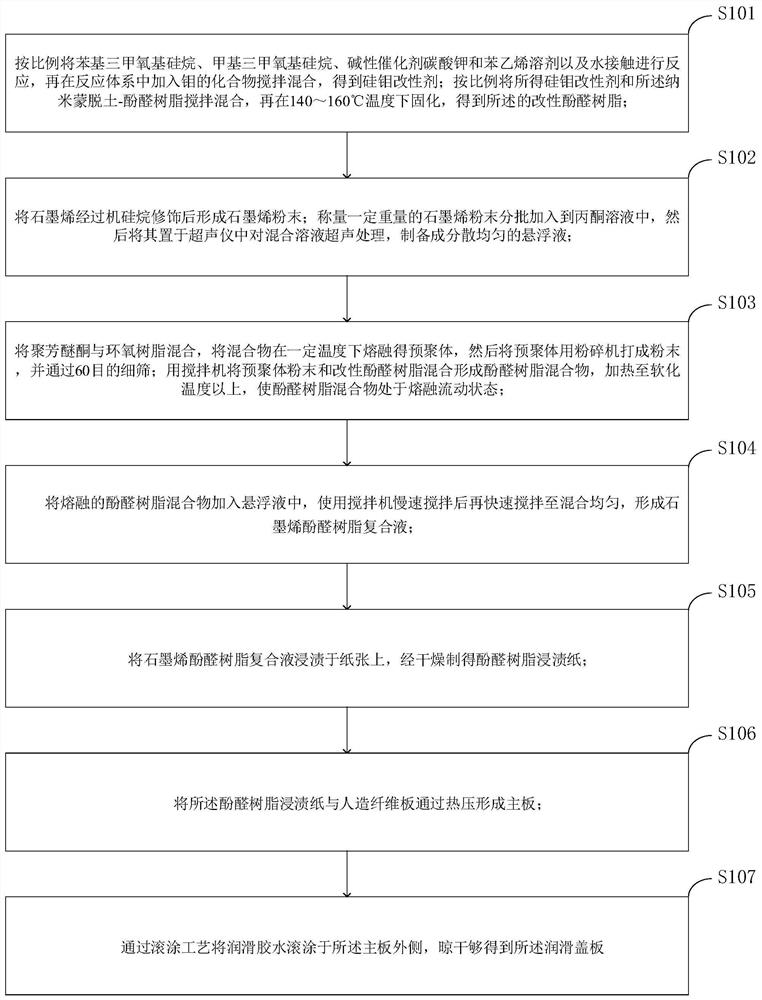

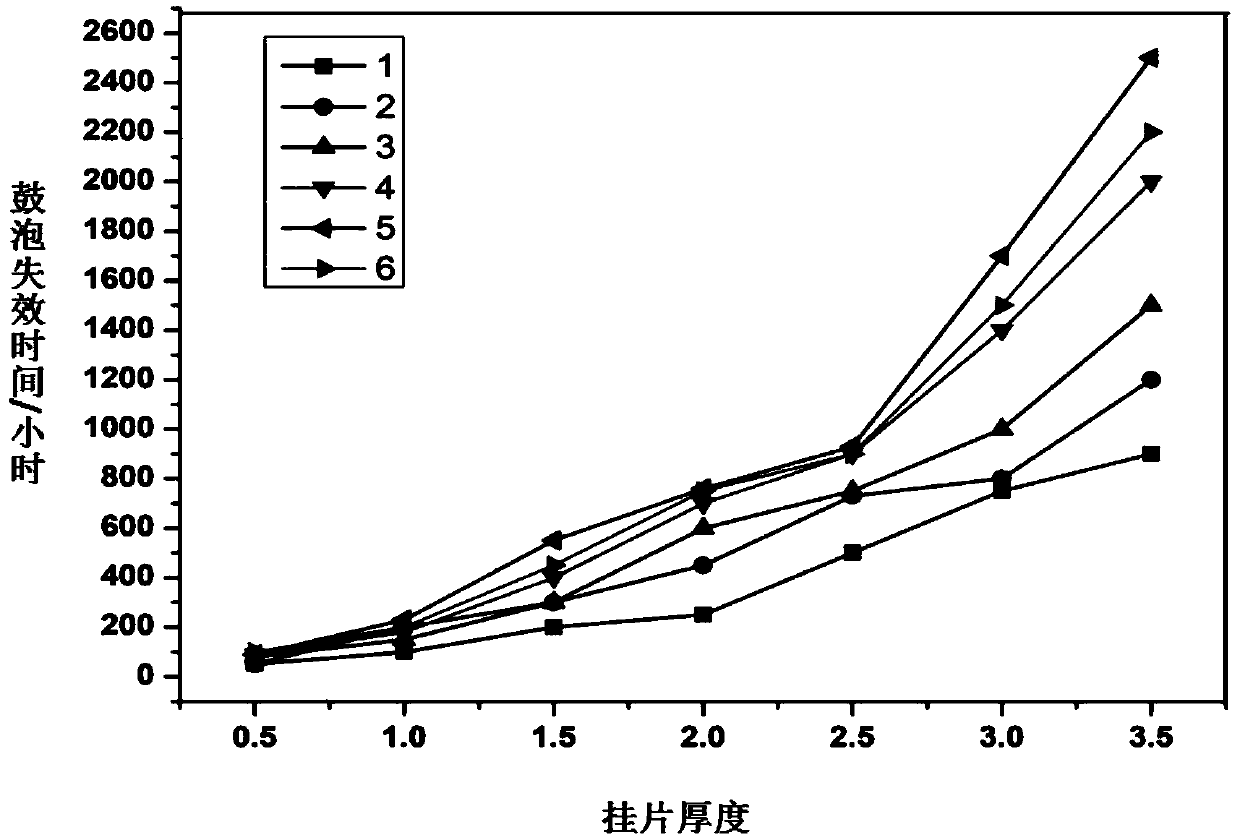

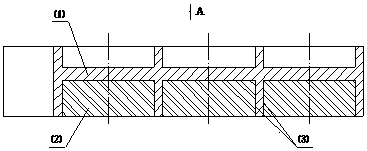

Lubricating cover plate and preparation method

InactiveCN112339385AIncrease the degree of cross-linkingHigh decomposition temperatureSynthetic resin layered productsPaper coatingFiberSolid wood

The invention belongs to the technical field of lubricating cover plates, and discloses a lubricating cover plate and a preparation method thereof. The outer side of a DE main plate layer of the lubricating cover plate is wrapped with a lubricating glue layer, and the main plate layer is formed by stacking multiple layers of phenolic resin plates and artificial fiber plates through hot pressing; the phenolic resin plate comprises paper and phenolic resin composite layers located on the two sides of the paper. The artificial fiber plate is at least one of a high-density fiber plate, a medium-density fiber plate, a solid wood particle plate, a recycled paper pulp plate and a bamboo fiber plate. The organic silicon containing methyl or phenyl is used as a modifier component, so that the decomposition temperature of a main structure is increased, the crosslinking degree of the cured modified phenolic resin is increased, and the heat resistance, corrosion resistance and mechanical properties of the modified phenolic resin are obviously enhanced; a molybdenum compound material is used as a modifier component, so that the erosion resistance and the abrasion resistance of the phenolic resin material can be improved, a relatively large friction resistance coefficient is maintained, and meanwhile, the phenolic resin material has relatively high heat resistance.

Owner:广东中晨电子科技有限公司

Abrasion-resistant flow guide device

InactiveCN102226663AReduce fluid flow rateModerate local abrasionCorrosion preventionHeat exchanger casingsEngineeringStreamflow

The invention discloses an abrasion-resistant flow guide device which comprises a suction flange, a buffer channel and a first rectangular flange connected with the inlet of a heat exchanger, wherein the suction flange, the buffer channel and the first rectangular flange are sequentially connected with a system pipeline; the buffer channel comprises a Z-shaped buffer distribution channel; and at least a flow guide vane is arranged in the outlet of the Z-shaped buffer distribution channel. In the abrasion-resistant flow guide device disclosed by the invention, the buffer distribution channel is in a Z shape, thus the flowing angel change of the solid-liquid phase fluid in the Z-shaped buffer distribution channel is great and the buffer effect is good. Furthermore, the effective flow space in the Z-shaped buffer distribution channel is large and the flow velocity of the fluid when the flow is the same is low, thereby effectively reducing the partial abrasion of the plate beam of a heat exchanger by a solid-liquid phase flow.

Owner:SHANGHAI HEAT TRANSFER EQUIP

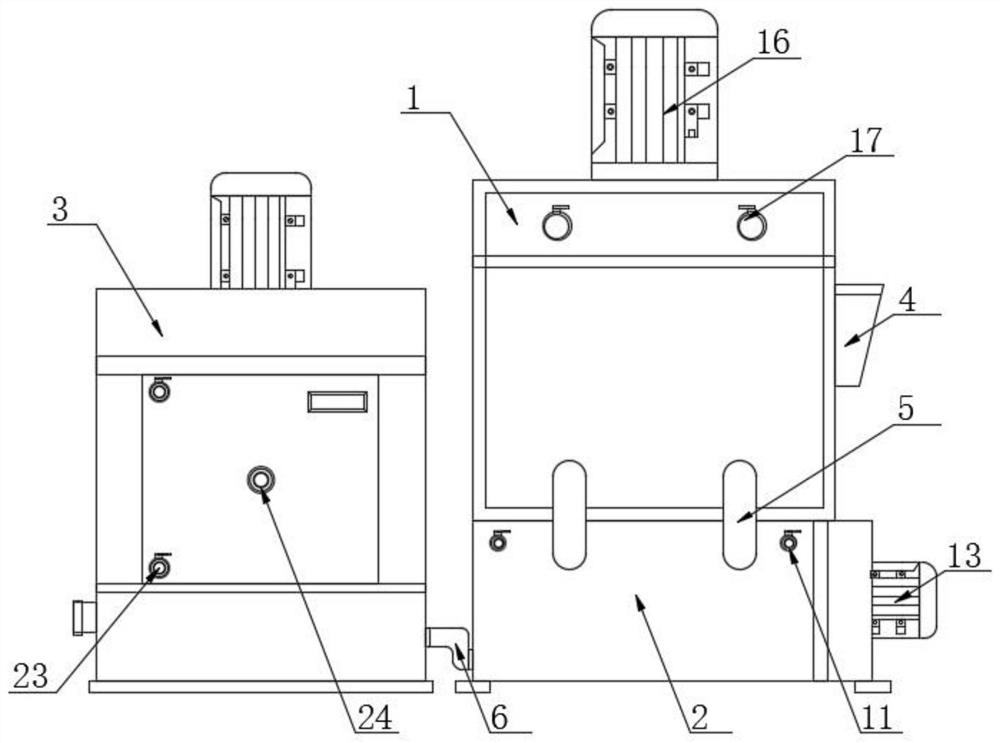

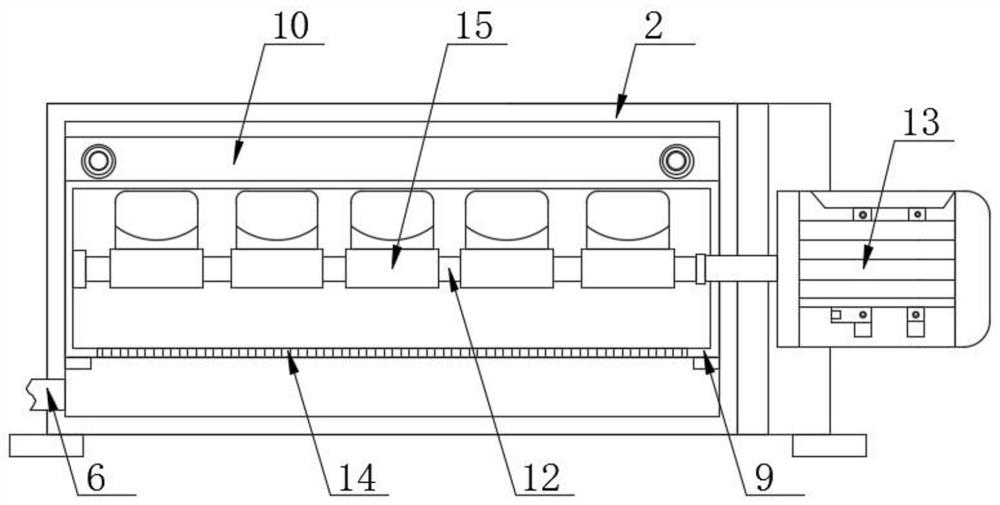

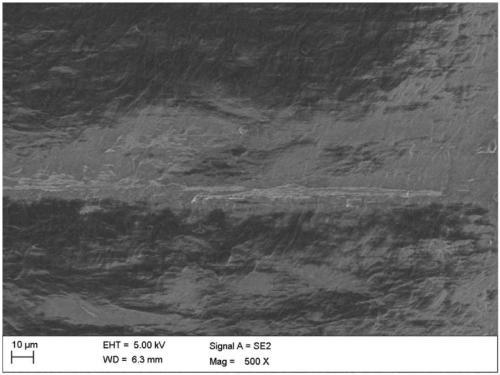

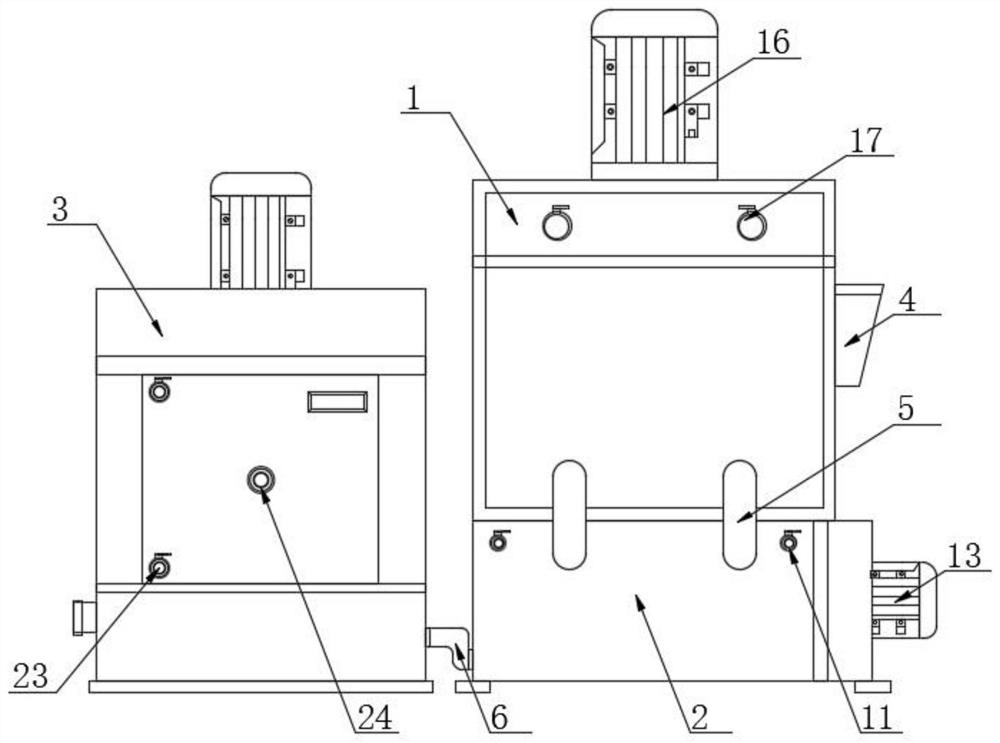

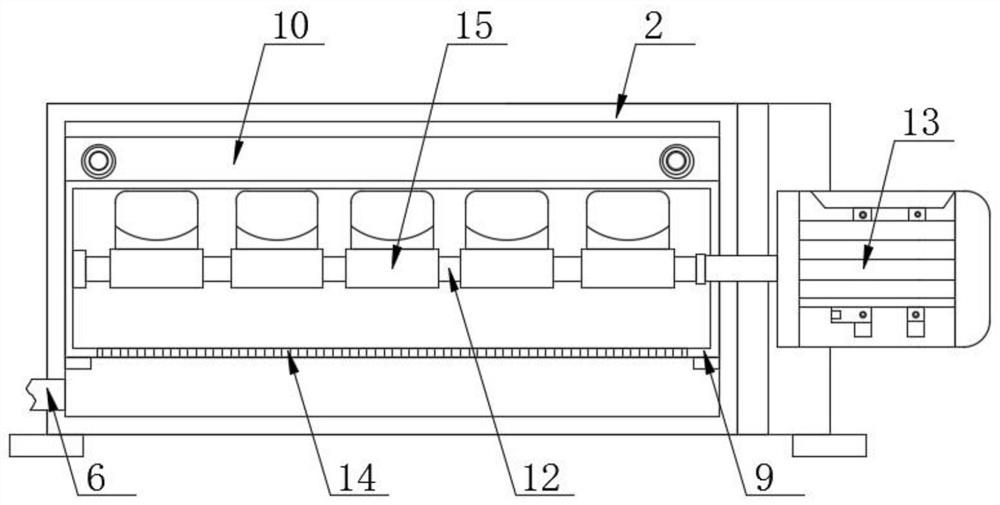

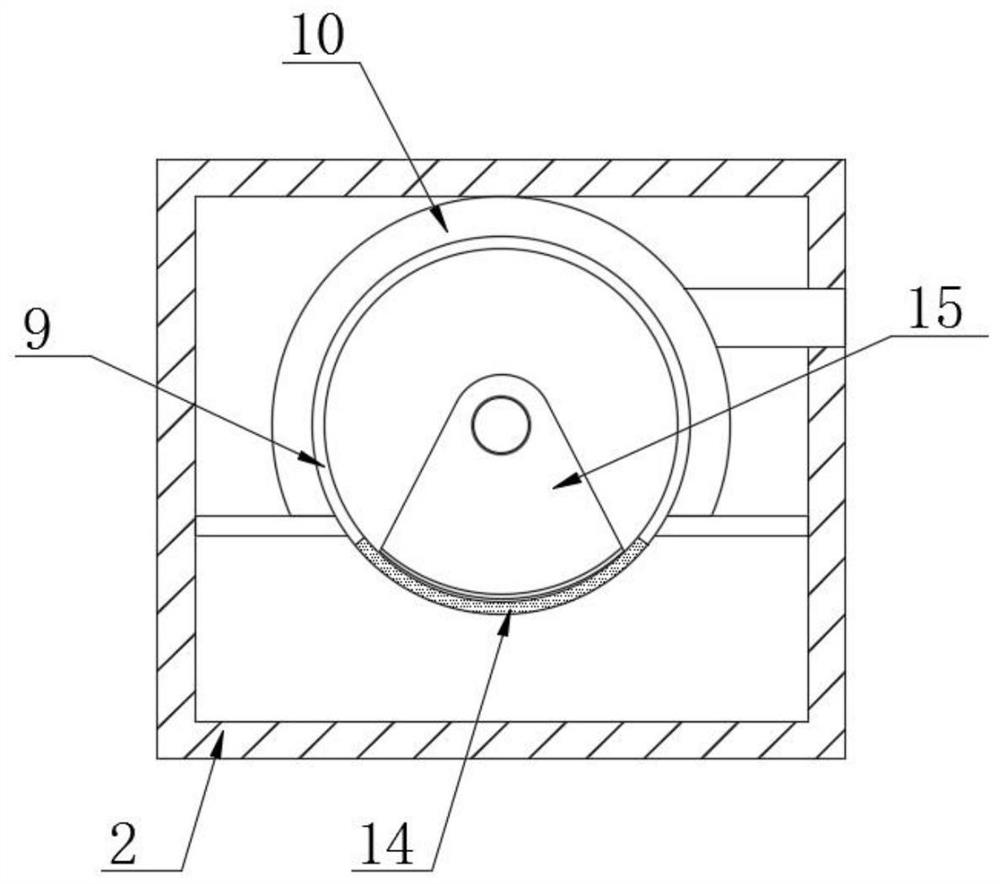

Preparation method and device of iron oxide pigment

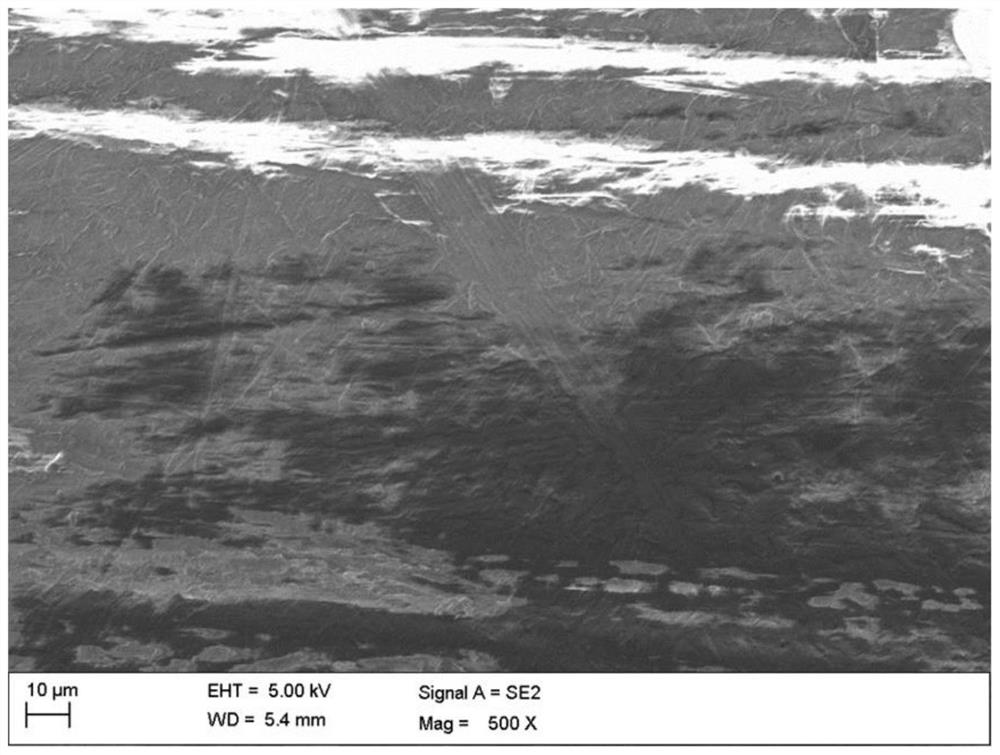

ActiveCN113122020AImproved abrasivenessUniform particle sizeTransportation and packagingMixer accessoriesFluidized bedPhysical chemistry

The invention discloses a preparation method of an iron oxide pigment, and relates to the technical field of iron oxide pigment preparation, and the preparation method specifically comprises the following steps: crushing and pulping a pigment filter cake, grinding slurry, carrying out color mixing treatment on the ground color paste, and finally granulating and drying through a spray drying tower and a fluidized bed system. According to the preparation method of the iron oxide pigment, slurry entering the grinding frame is heated, particles of the heated slurry are expanded, the grinding performance of the particles of the slurry is obviously improved, the particles in the slurry are rapidly ground between the grinding block and the filter screen, in this way, the particle size of the prepared iron oxide pigment can be kept uniform, meanwhile, the preparation efficiency of the iron oxide pigment can be improved, slurry in the color mixing tank is heated through steam, particulate matter in the slurry is kept in an active state, the high-speed stirring effect of the material mixing frame is matched, and the mixing effect and the mixing speed of the color paste are effectively improved.

Owner:TONGLING RELY TECH

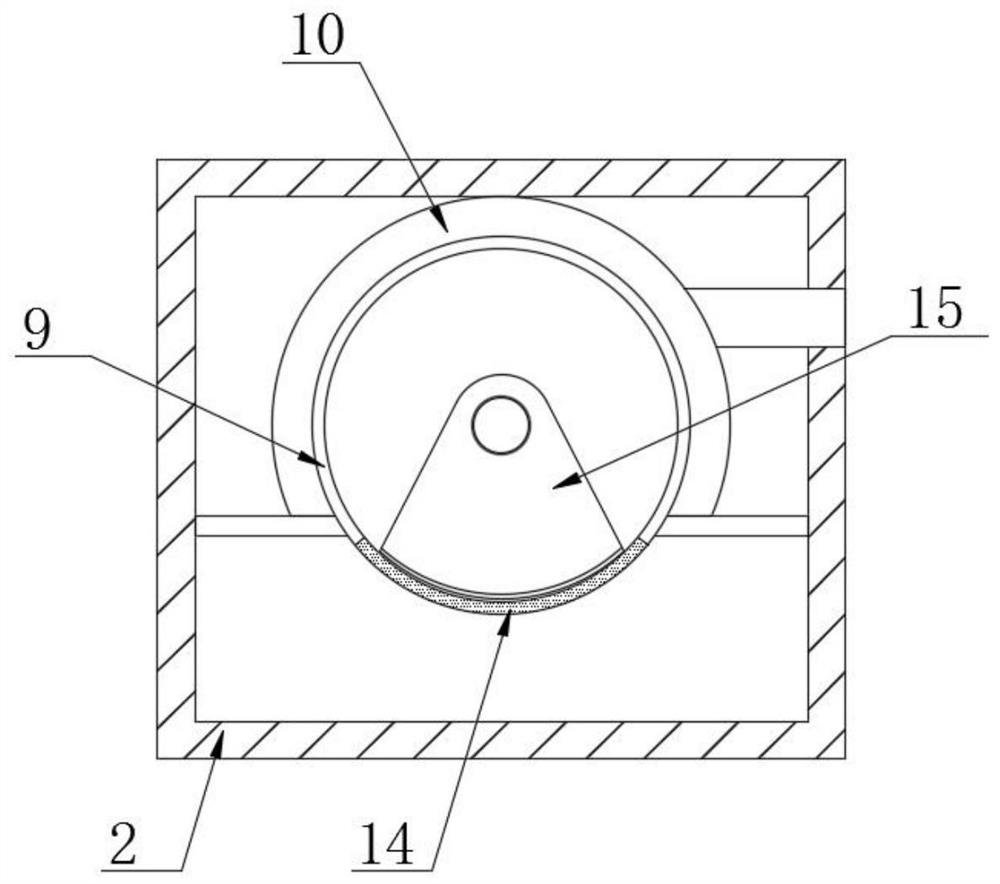

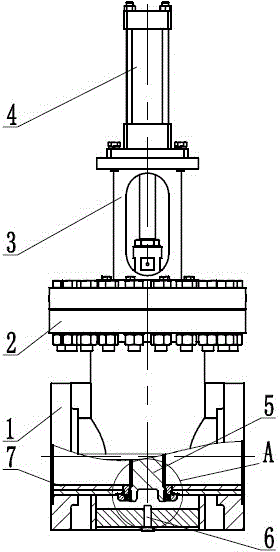

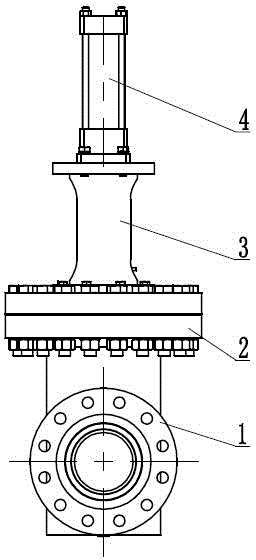

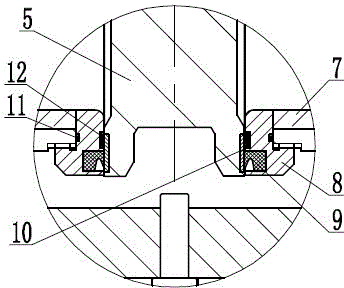

Novel high-medium-low-pressure wear-resisting double-gate-disc ash gate valve

The invention relates to a novel high-medium-low-pressure wear-resisting double-gate-disc ash gate valve. The gate valve comprises a valve body, two valve seats, a valve deck, gate discs and a driving mechanism of the gate discs and is characterized in that each valve seat is in the shape of a flange, the two valve seats are connected to the inner ends of flow channels on the two sides of the valve body respectively, an O-shaped sealing ring is arranged between each valve seat and a valve body contact surface, annular grooves corresponding to the valve seat sealing surfaces are formed in the two side faces of each gate disc respectively, hard alloy is arranged in each annular groove through bead welding, an inner annular groove and an outer annular groove are formed in each valve seat sealing surface, hard alloy is arranged in each inner annular groove through bead welding or a ceramic ring is embedded in each inner annular groove, and each outer annular groove is filled with a soft sealing ring. The gate valve is reasonable in structural design, reliable in use, and capable of fundamentally solving the problems of an existing ash gate valve that wearing occurs easily, sealing performance is poor, service life is short, maintenance is not easy, and using cost is high, wearing resistance and sealing performance are improved remarkably, service life is prolonged, and maintenance is facilitated.

Owner:LIAONING MINGDE MAGNETIC POWER TECH CO LTD

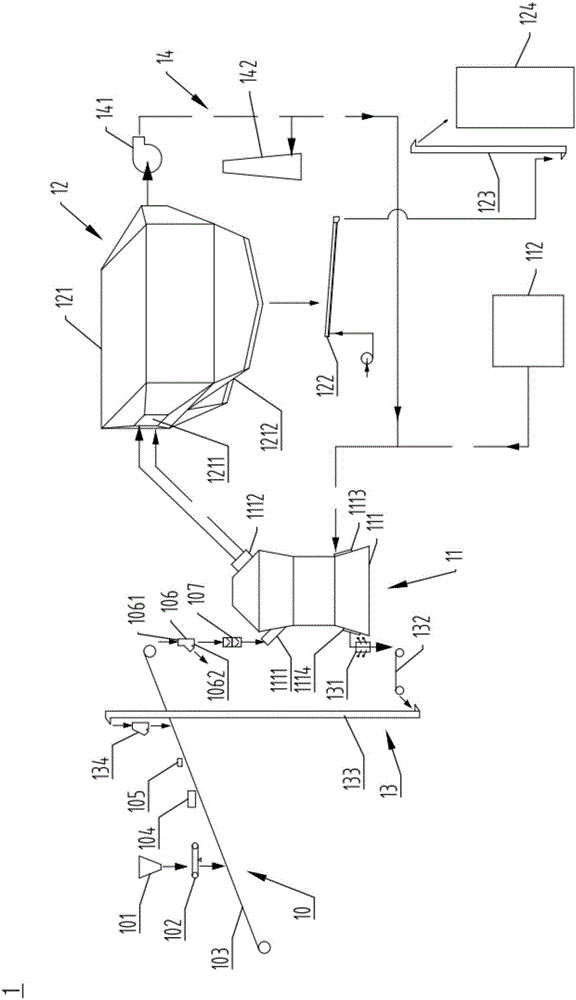

Phosphorous slag pulverizing system

The invention relates to a phosphorous slag pulverizing system. The phosphorous slag pulverizing system comprises a phosphorous slag feeding device, a phosphorous slag pulverizing device and a discharging device; the phosphorous slag feeding device is connected with the phosphorous slag pulverizing device; the discharging device is connected with the phosphorous slag pulverizing device; the phosphorous slag pulverizing device comprises a vertical mill and a hot blast furnace; the vertical mill is connected with the phosphorous slag feeding device; the hot blast furnace is connected with an air inlet of the vertical mill; and fuel of the hot blast furnace is tail gas of a yellow phosphorous production line. According to the phosphorous slag pulverizing system, phosphorous slag is pulverized through the vertical mill; and the land area occupied by the vertical mill is small, and the land utilizing efficiency is improved. Besides, the tail gas generated by the yellow phosphorous production line serves as the fuel of the hot blast furnace so that the hot blast furnace can generate hot air, or waste gas generated by the system is used for drying the phosphorous slag in the vertical mill, not only is the waste gas reused, but also the water content of the phosphorous slag is reduced, the grindability and abradability of the phosphorous slag are improved, the electric consumption of the whole system can be controlled at 42 kWh / ton, the production efficiency is improved, and the yield is increased.

Owner:JIANGSU XINYE HEAVY IND

Fabrication method for hot pressing diamond bit with added aluminium oxide hollow balls

The invention relates to a fabrication method for a hot pressing diamond bit with added aluminium oxide hollow balls. The method comprises the following processes: allowing the aluminium oxide hollow balls and the diamonds to be subjected to pelletization and film applying; uniformly mixing the film applied aluminium oxide hollow balls, the diamonds and bit matrix powder subjected to ball milling and an adhesive; weighing the mixture and filling into a graphite die according to the required amount of each of drill bits in various specifications; pressing a drill bit steel basal body on the graphite die which is then delivered into an mid-frequency electric furnace and pressing machine all-in-one machine for sintering, wherein the hot pressing pressure is 15-16 MPa, the boiler temperature is 950-960 DEG C, the heat-insulating time is 4-5 min, and the discharging temperature is 815-830 DEG C; and after discharging, slowly cooling to the ambient temperature under the heat-insulating condition, and carrying out demoulding so as to fabricate the drill bit provided by the invention. According to the invention, the diamond volume concentration of the diamonds in a fan-shaped cutting operating block of the drill bit is 11-13 percent, and the volume concentration of the aluminium oxide hollow balls is 12-18 percent. The drill bit is used for drilling objects that are as hard as that of hard and compact rocks; and average drilling effectiveness is improved by 95 percent, and the service life is improved by 80 percent as compared with a general diamond bit.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

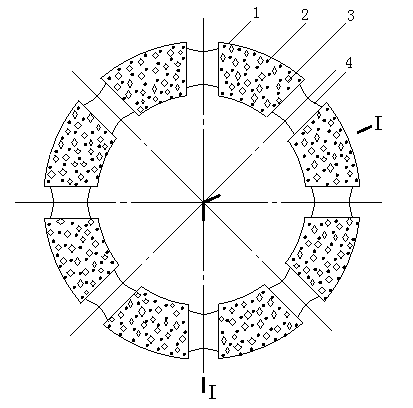

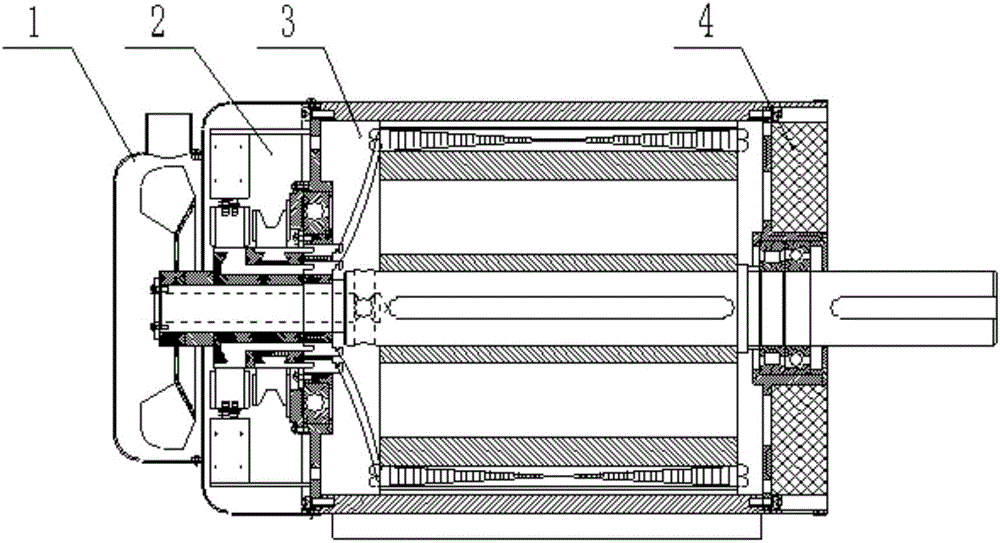

Multi-power motor for electric vehicle

ActiveCN106130232ASave electricityReduce demandElectric machinesCooling/ventillation arrangementElectric vehicleComputer fan

The invention discloses a multi-power motor for an electric vehicle. The multi-power motor for the electric vehicle comprises a cooling fan part, a commutating electric brush part, a stator-rotor part and an air filtering part, wherein the cooling fan part comprises a main shaft, cooling fans and a cooling fan shell; the rectifying electric brush part comprises electromagnets, a commutator, a commutator changeover panel, an electric brush group, top bearings and a commutating electric brush shell; the stator-rotor part comprises a stator-rotor shell, a stator, a coil winding and a rotor; and the air filtering part comprises a tail bearing, an air filter element, an end cover and support upright posts. By the motor, the output power and the mechanical characteristic of the motor can be adjusted according to a working condition change; lifting and falling of electric brushes are controlled through controlling power-on and power-off modes of the electromagnets; the commutator changeover panel is connected to coils with different numbers of turns; the power output and the mechanical characteristic of the motor are changed; and different working modes are achieved to deal with the working condition change.

Owner:HEBEI UNIV OF TECH

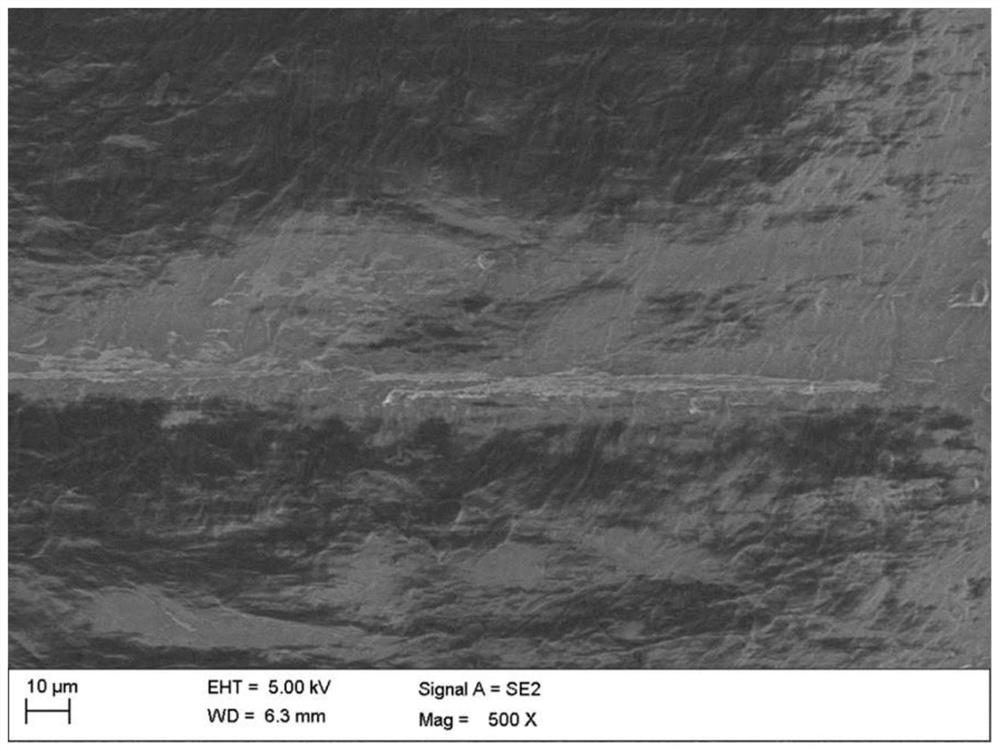

Modified phenolic resin, preparation method thereof, and modified phenolic resin plate

ActiveCN109651758AIncrease the degree of cross-linkingImprove heat resistanceSolventMechanical property

The invention belongs to the technical field of polymer material modification, and provides a modified phenolic resin, a preparation method thereof, and a modified phenolic resin plate. The modified phenolic resin is prepared by reacting 20-30 wt% of a silicon-molybdenum modifier and 70-80 wt% of nano-montmorillonite-phenolic resin, and the sum of the weight percentages of the above two raw materials is 100 wt%; and the silicon-molybdenum modifier adopts a compound prepared by reacting 10-15 wt% of phenyltrimethoxysilane, 5-10 wt% of methyltrimethoxysilane, 0.5-1 wt% of a basic catalyst potassium carbonate, 20-25 wt% of a styrene solvent, 10-15 wt% of water and 35-50 wt% of molybdenum, and the sum of the weight percentages of all above raw materials is 100 wt%. The heat resistance, the corrosion resistance and the mechanical properties of phenolic resin are significantly improved, and the large anti-friction coefficient is kept.

Owner:CHINA SHENHUA ENERGY CO LTD +1

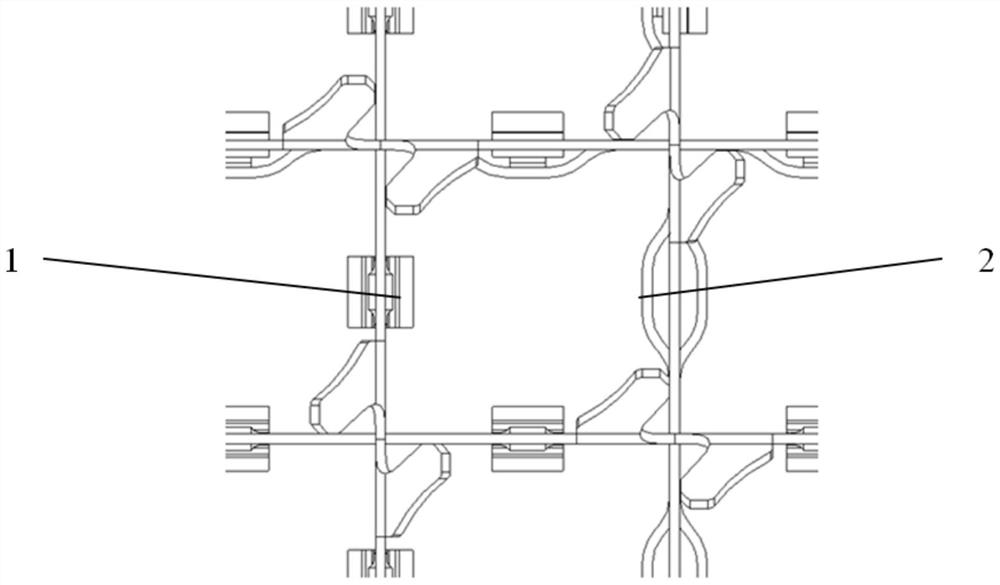

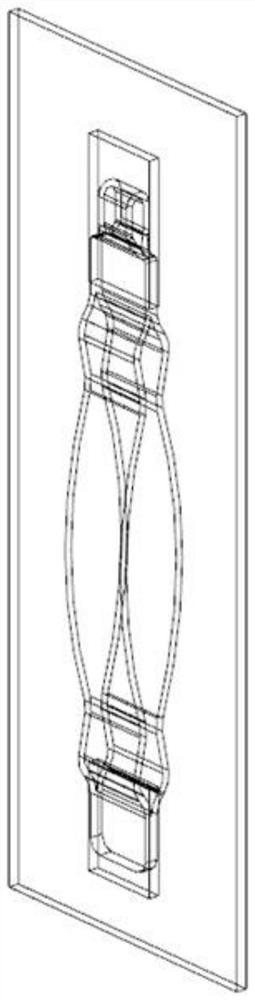

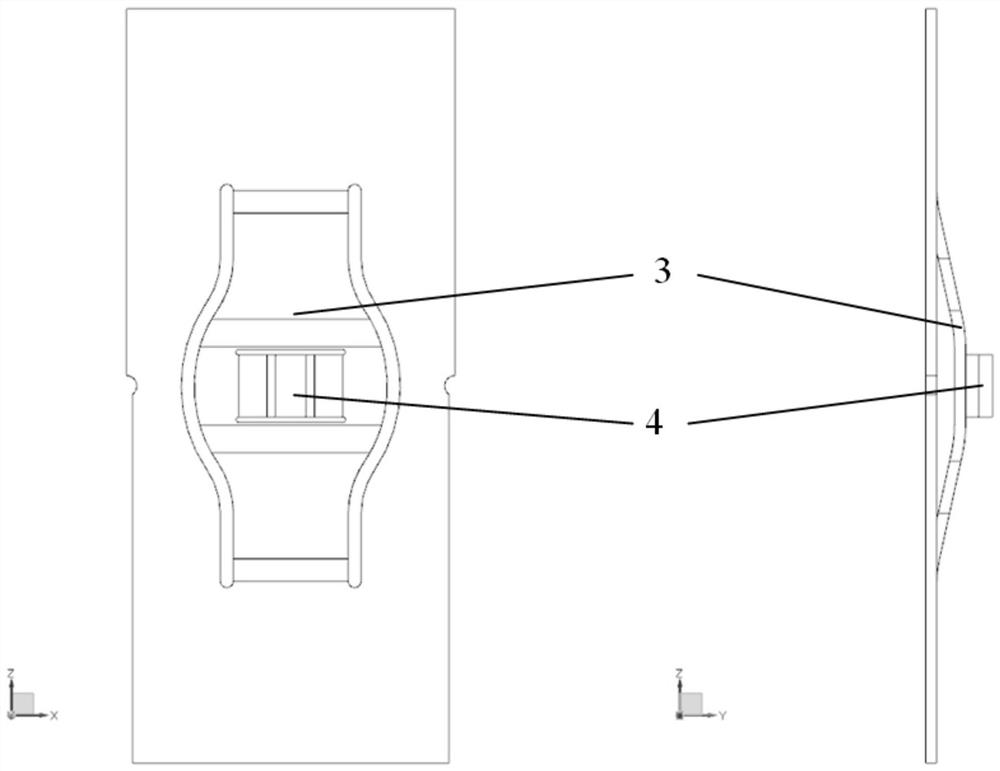

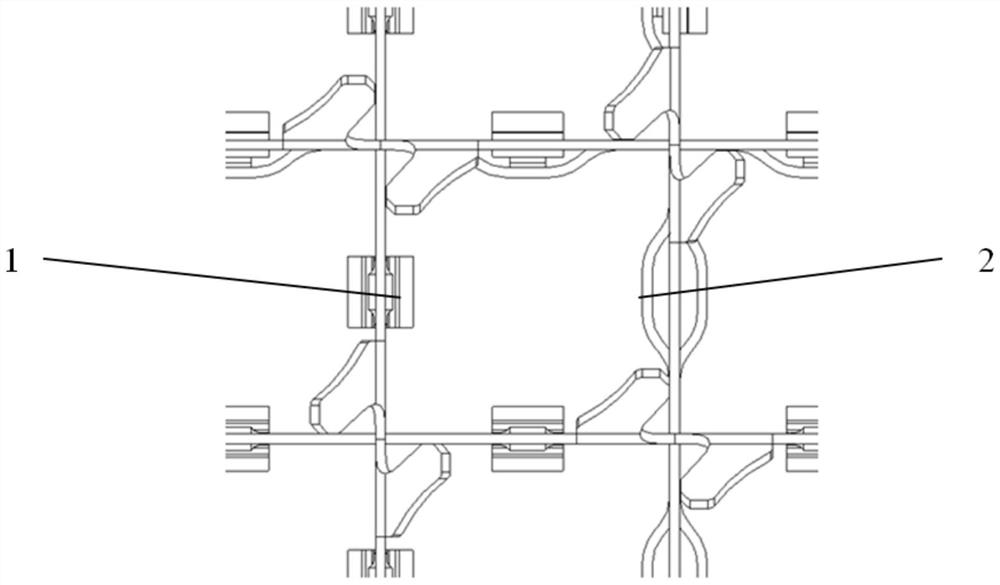

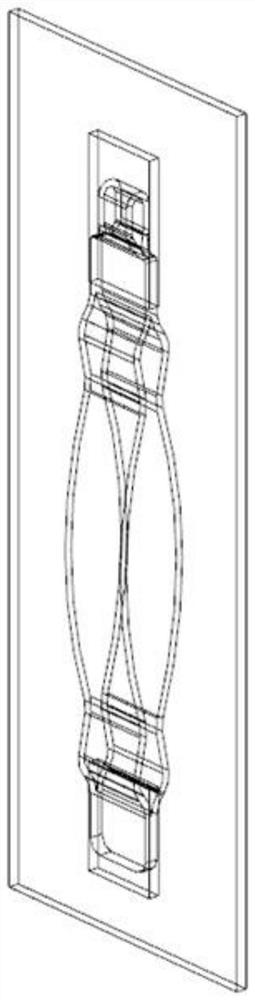

Grillwork spring capable of improving abrasion resistance and reducing resistance and positioning grillwork

ActiveCN113362973AImprove flowReduce resistanceNuclear energy generationFuel element assembliesEngineeringMechanical engineering

Owner:NUCLEAR POWER INSTITUTE OF CHINA

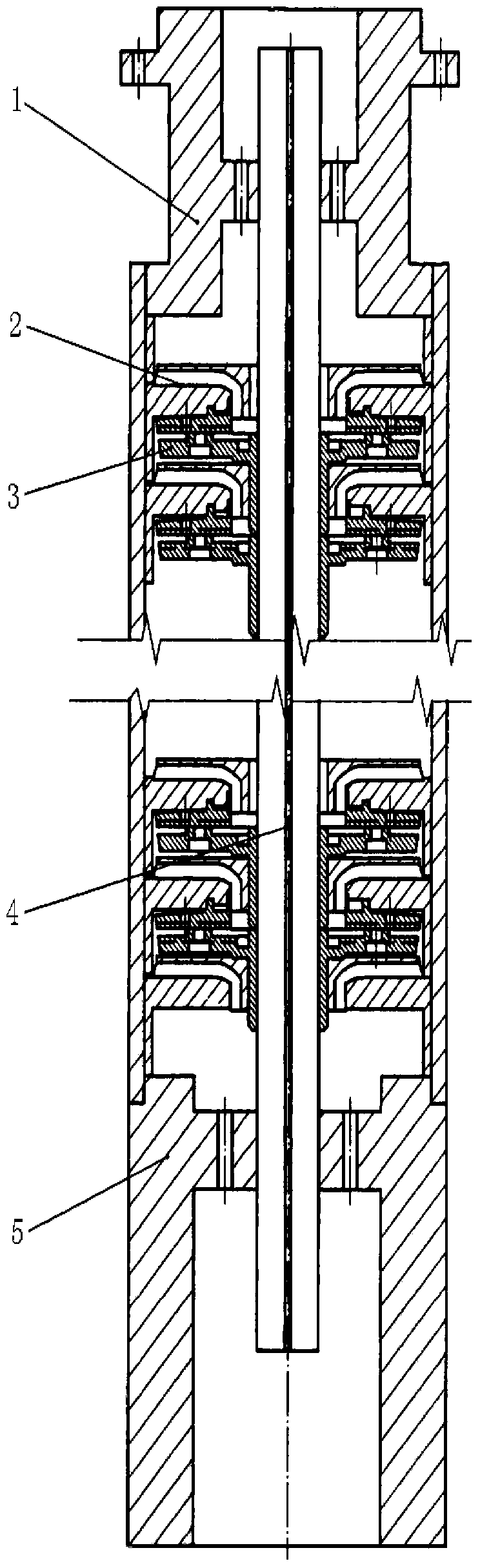

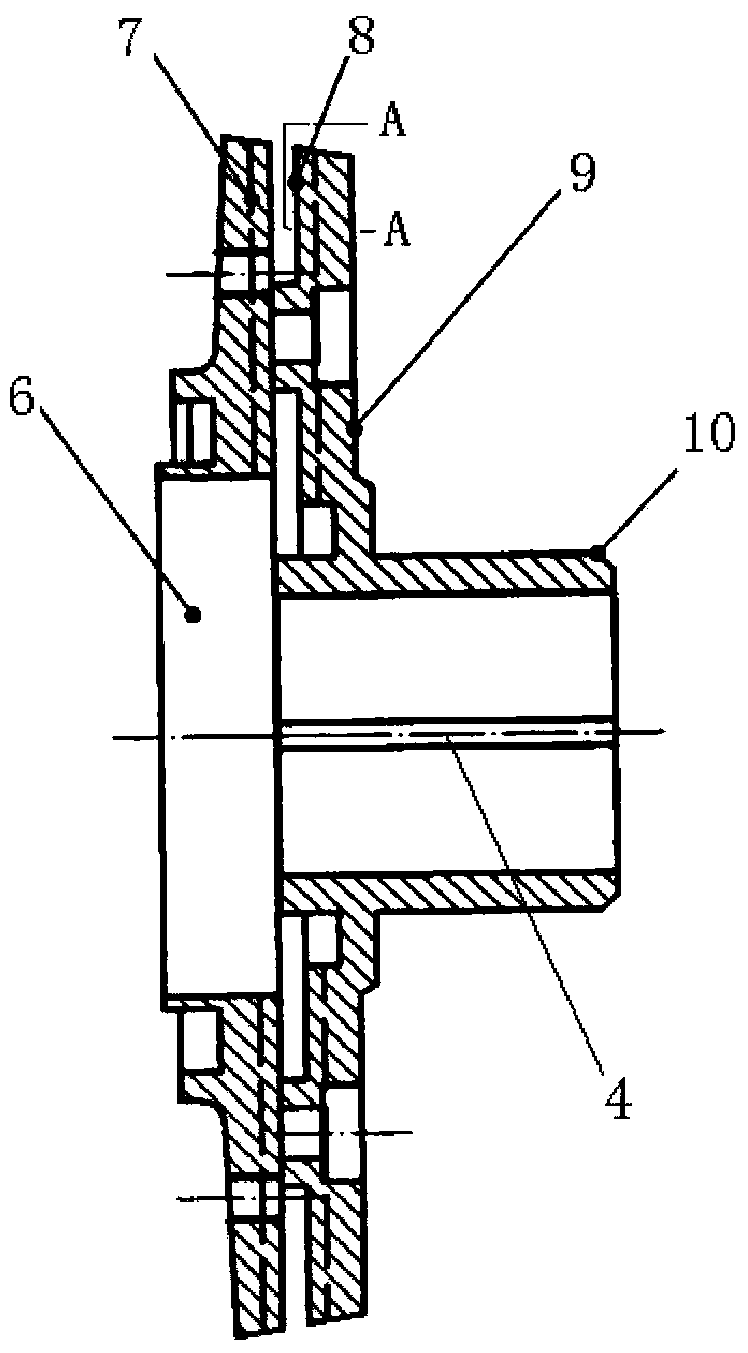

Multifunctional submersible mixed transportation vortex pump

InactiveCN104329259ASo as not to damageNo performance degradationSpecific fluid pumpsPump componentsImpellerCavitation

The invention discloses a multifunctional submersible mixed transportation vortex pump. The vortex pump comprises a suction inlet, a guide impeller, a vortex impeller, a pump shaft and a discharge head, wherein the suction inlet is connected with the guide impeller, the vortex impeller and the discharge head in sequence into a whole; the pump shaft penetrates through the centers of the suction inlet, the guide impeller, the vortex impeller and the discharge head. The vortex pump has the characteristics of high corrosion resistance, freeness from collision components, low required power, high treatment viscosity, high efficiency, prevention of emulsification effect on well fluid, multiple functions, high suitability, realization of mixed transportation of gas and liquid, fundamental elimination of blockage, cavitation, excessive wear, running reliability, high efficiency, low maintenance, long service life and the like, and is widely applied to petroleum suction and conveying processes; the treatment viscosity of viscous media is up to 300,000Pa.c, the required power is low and is not up to a half that of a pump of the same specification, blockage is prevented, the conveying percent of solid particles is up to 75 percent, high and low-viscosity well fluid of which the gas content is up to 68 percent can be conveyed, and all the phenomena influencing the pump performance such as blockage, cavitation, excessive wear, damage and the like are avoided fundamentally.

Owner:DONGYING CITY XIN BAO MACHINERY MFG

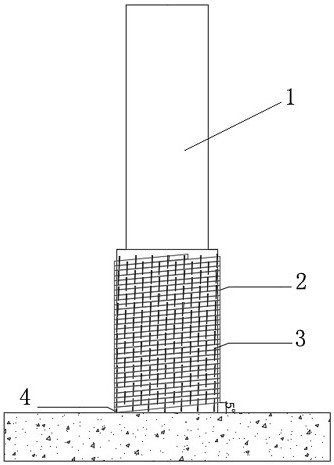

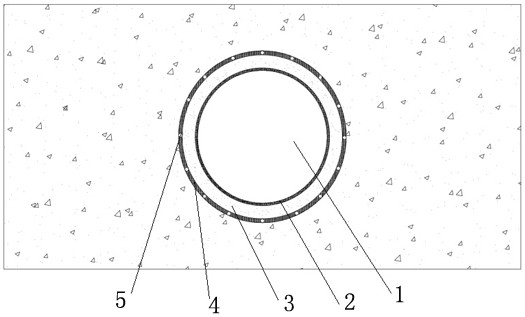

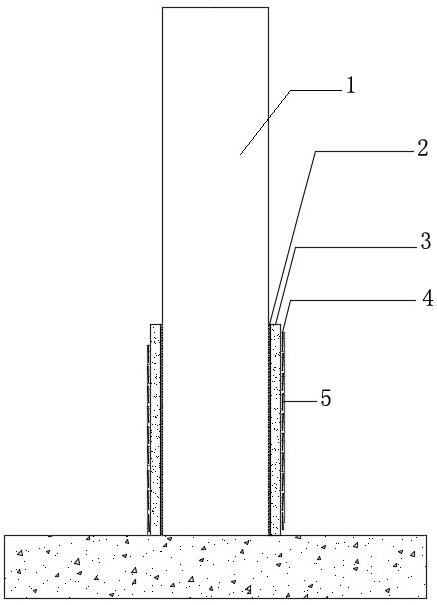

A repair anti-scouring structure and construction method based on tire strip pier

ActiveCN113089506BOverall coordination and beautyLittle influence on flow sectionClimate change adaptationBridge structural detailsWaste tiresPier

The invention proposes a repair anti-scouring structure and construction method based on tire strip pier, which is used to solve the problem of how to improve the ability to resist the impact and abrasion of stones in floods during the reinforcement process of damaged pier in the ditch, and at the same time realize the rapid recovery of pier after reinforcement during the flood period. Detection technical problems. The anti-scouring structure includes an anti-scouring piece sleeved on the lower part of the pile body. The anti-scouring piece is in order from the inside to the outside: a carbon fiber cloth detection layer, a cement mortar protection layer and a tire strip braided layer; the carbon fiber cloth detection layer is set on the At the lower part of the pile body, a cement mortar protective layer is arranged outside the carbon fiber cloth detection layer, and a tire strip braided layer is arranged outside the cement mortar protective layer. The invention uses the braided layer of waste tire strips to improve the anti-scouring performance of the pier, and the carbon fiber cloth enhances the bending rigidity of the pier while using the electrical conductivity of the carbon fiber cloth to detect the damage of the reinforced pier. The whole structure is convenient and practical, with low cost and high durability.

Owner:HENAN UNIVERSITY

A kind of modified phenolic resin and preparation method thereof, modified phenolic resin plate

ActiveCN109651758BIncrease the degree of cross-linkingImprove heat resistancePolymer scienceMontmorillonite

The invention belongs to the technical field of modification of polymer materials, and provides a modified phenolic resin and a preparation method thereof, and a modified phenolic resin plate. The modified phenolic resin is prepared by reacting raw materials including the following components: The total weight is 100wt%, 20-30wt% silicon-molybdenum modifier, 70-80wt% nanometer montmorillonite-phenolic resin; the silicon-molybdenum modifier is prepared by using various reaction raw materials including the following weight percentages: The total weight of each reaction raw material is 100wt%, 10-15wt% phenyltrimethoxysilane, 5-10wt% methyltrimethoxysilane, 0.5-1wt% alkaline catalyst potassium carbonate, 20-25wt% styrene solvent , 10-15wt% water, 35-50wt% molybdenum compound. The invention can obviously improve the heat resistance, corrosion resistance and mechanical properties of the phenolic resin, while maintaining a large anti-friction coefficient.

Owner:CHINA SHENHUA ENERGY CO LTD +1

Graphene polymer energy-saving and environmental protection composite material coating and its preparation process and application

ActiveCN105623469BImprove thermal shock resistanceExcellent resistance to media penetrationFireproof paintsAnti-corrosive paintsCompound organicSilicon dioxide

Owner:田路兵

A kind of preparation method and device of iron oxide pigment

ActiveCN113122020BImprove abrasivenessUniform particle sizeTransportation and packagingMixer accessoriesFluidized bedPhysical chemistry

The invention discloses a method for preparing an iron oxide pigment, which relates to the technical field of iron oxide pigment preparation, and specifically includes crushing and beating the pigment filter cake, grinding the slurry, and performing color mixing treatment on the ground color paste , and finally granulated and dried through a spray drying tower and a fluidized bed system. In the preparation method of the iron oxide pigment, by heating the slurry entering the inside of the grinding frame, the heated slurry particles are expanded, the grinding performance of the slurry particles is significantly improved, and the particles in the slurry are in the grinding block and the filter. Fast grinding between the nets, so that the particle size of the iron oxide pigment can be kept uniform, and at the same time, the preparation efficiency of the iron oxide pigment can be improved. Steam is used to heat the slurry in the color mixing tank to make the slurry The particles in the mixture remain active, and with the high-speed stirring effect of the mixing rack, the mixing effect and mixing speed between the color pastes are effectively improved.

Owner:TONGLING RELY TECH

A grid spring and positioning grid with improved anti-abrasion performance and reduced resistance

ActiveCN113362973BImprove flowReduce resistanceNuclear energy generationFuel element assembliesEngineeringMechanical engineering

Owner:NUCLEAR POWER INSTITUTE OF CHINA

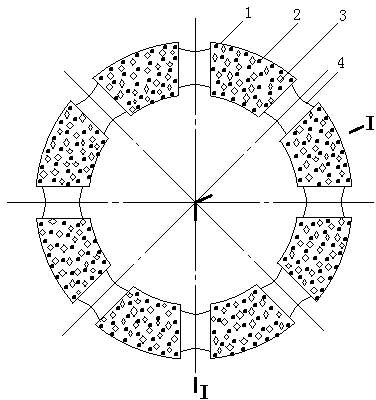

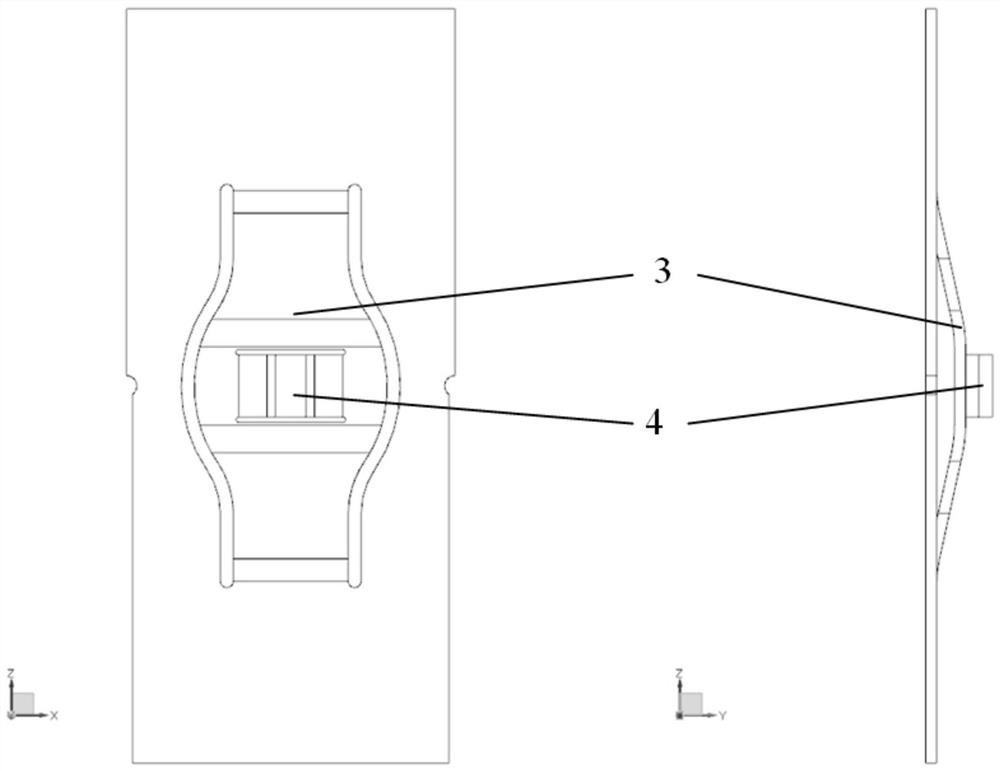

Metal magnetic lining plate for enhancing magnetic field distribution

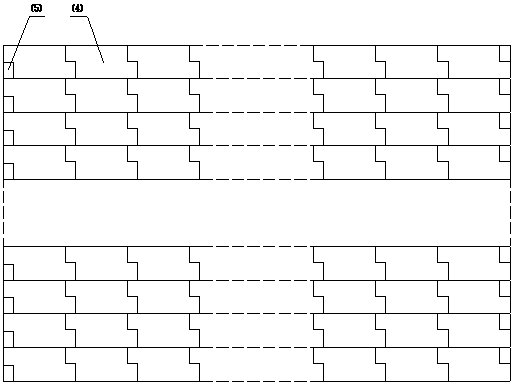

InactiveCN108057485AImprove structural strengthImproved ability to withstand load shock and abrasionMagnetsSheets/panelsMetallic materialsAdhesive

The invention relates to a metal magnetic lining plate for enhancing magnetic field distribution, wherein the metal magnetic lining plate is used for protecting an inner surface of a mill barrel bodyand a device ferromagnetism metal surface making contact with a material during material transporting and reducing abrasion of the surfaces; the metal magnetic lining plate consists of an outer shell(1), magnetic block groups (2) and an adhesive. The outer shell (1) is made of a metal material which is not magnetically conductive, and is shaped as a box consisting of a plurality of cubic lattices, and two adjacent rows of lattices are in staggered arrangement. The magnetic block groups (2) are loaded in the lattices (3), the polarity directions of the magnetic block groups (2) loaded in the lattices (3) make the polarities of the magnetic block groups (2) in the same row the same, and the polarities of the magnetic block groups (2) in two adjacent rows are opposite. The staggered arrangement of the adjacent two rows of lattices leads to staggered arrangement of two adjacent rows of magnetic block groups (2). The staggered arrangement of the two adjacent rows of lattices of the outer shell can enhance the structural strength compared with aligned arrangement, and thus the ability to withstand the impact of the mill load is increased. The staggered arrangement of the adjacent two rows of magnetic block groups (2) can makes up short interruption existing in a magnetic field during aligned arrangement, the continuity and integrity of the magnetic field are increased, the magneticfield distribution is enhanced, a protective layer formed by broken steel balls and a ferromagnetic material and adsorbed on a work surface of the magnetic lining plate is more firm, and the life of the lining plate is prolonged.

Owner:BEIJING HIGH MILL TECH CO LTD

Welding method of 12cr5mo martensitic stainless steel

ActiveCN106312242BSmall coefficient of thermal expansionImprove performanceArc welding apparatusWelding/cutting media/materialsSlagMartensitic stainless steel

The invention relates to a welding method for 12Cr5Mo martensite stainless steel. The welding method comprises the following steps: step I, preparing a 12Cr5Mo martensite stainless steel groove, carrying out butt-joint assembly on the groove, and pre-heating a welded part of the groove at a pre-heating temperature being 100-150 DEG C; and step II, separately carrying out a primary welding process, a secondary welding process and a tertiary welding process on the welded part of the groove by use of a welding rod, wherein the welding rod is composed of a welding core and a coating; and the welding core consists of the following raw materials: C, Ni, Cr, Mn, Si, Ti, Nb, V, Ta, Zr, La, Ce, Pr, W, N and Fe. The coating consist of the following components: rutile, titanium dioxide, potassium feldspar, mica, calcium carbonate, nitrogen containing ferrochromium, electrolytic manganese, metal nickel, ferrocolumbium, magnesium oxide, yttrium oxide, sodium fluosilicate, hydroxypropyl methyl cellulose, phenolic resin and melamine. According to the welding method, a welding process is simple, welding seam molding is beautiful, slag is easily separated and deposition efficiency is high; and the obtained welding seam metal has excellent mechanical performance and mechanical property.

Owner:THE SIXTH CONSTR CO LTD OF CHINA NAT CHEM ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com