Novel high-medium-low-pressure wear-resisting double-gate-disc ash gate valve

A double gate, low pressure technology, applied in the direction of sliding valve, valve device, engine components, etc., can solve the problems of short service life, high use cost, difficult maintenance, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

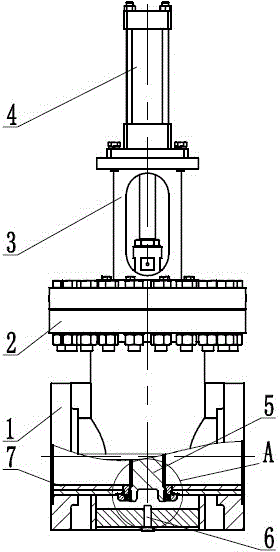

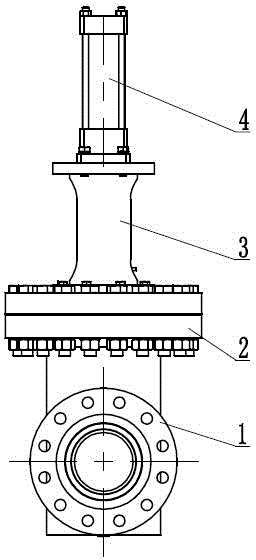

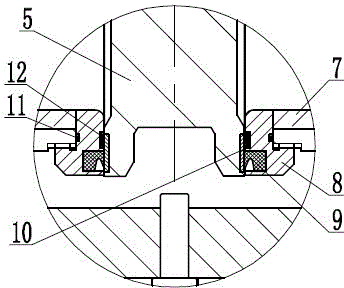

[0028] Such as Figure 1 ~ Figure 3 As shown, the new type high, medium, and low pressure wear-resistant double gate ash gate valve includes a valve body 1, a valve seat 8, a valve cover 2, a gate 5 and a drive mechanism thereof. The valve seat 8 is in the shape of a flange. There are two in number, which are respectively connected to the inner ends of the flow passage on both sides of the valve body 1 with threads (or bolts), and a 0-shaped sealing ring 11 is provided between the contact surface of the valve seat 8 and the valve body 1. The two sides of the gate 5 are respectively provided with annular grooves corresponding to the sealing surface of the valve seat 8, and the gate sealing cemented carbide 10 is overlaid in the annular groove. The sealing surface of the valve seat 8 is provided with inner, The outer ring groove and the inner ring groove are welded to the valve body to seal cemented carbide 12 or embedded ceramic ring. When the valve internal pressure is above 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com