High-gloss high-hardness water-based epoxy floor coating and preparation method thereof

A technology of epoxy floor and water-based epoxy, applied in the field of coatings, can solve the problems of slow film-forming speed of water-based floor paint, poor acid and alkali resistance, poor solvent resistance, and poor hardness of the coating film, and achieve gel time. Adjustable, no dust, water resistance, fast curing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] A high-gloss and high-hardness water-based epoxy floor coating, including A component and B component, A component is composed of liquid epoxy resin, multifunctional epoxy resin, hydrophilic modified multifunctional epoxy resin and the second A water-based emulsion prepared from deionized water; component B is composed of water-based epoxy curing agent, second deionized water, pigments and fillers, dispersants, defoamers, leveling agents, anti-scratch additives and colorants composition;

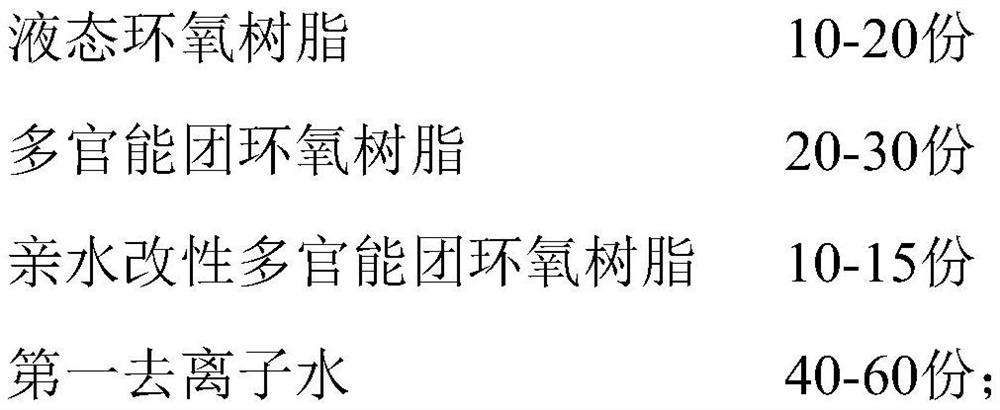

[0042] The A component includes the following raw materials in parts by weight:

[0043]

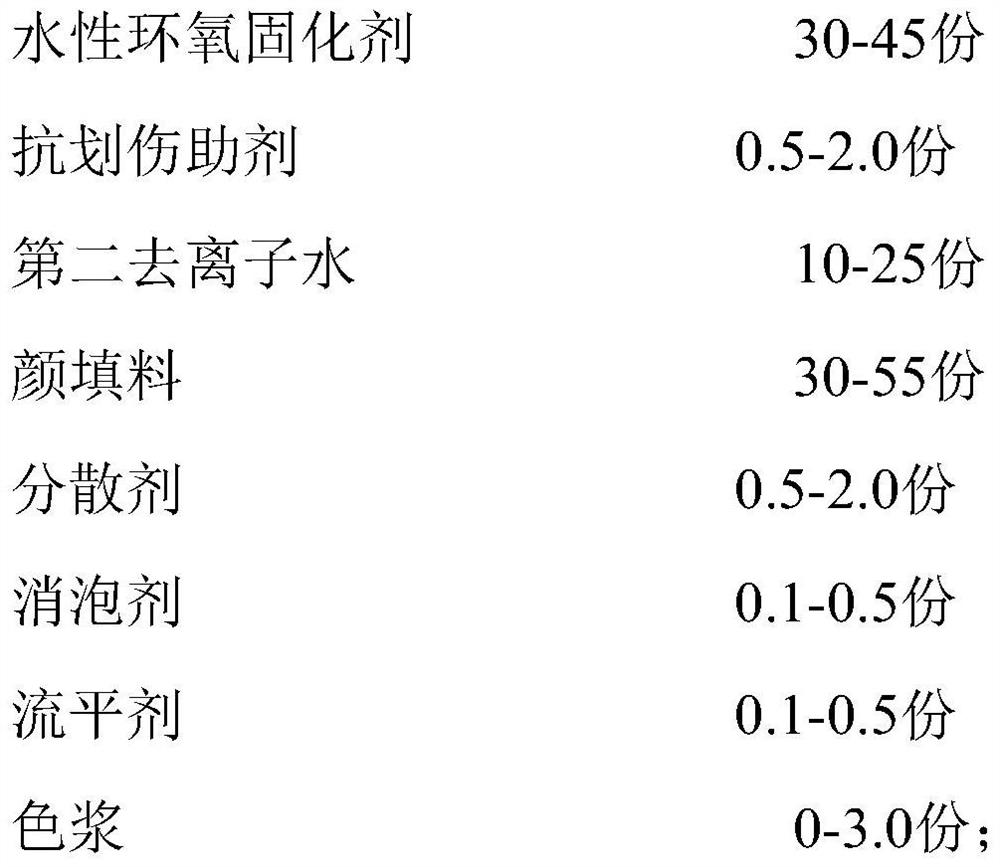

[0044] The B component includes the following raw materials in parts by weight:

[0045]

[0046] The mixing ratio of the A component and the B component is according to the amount of the epoxy group contained in the A component: the amount of the amino active hydrogen contained in the B component is 0.8:3; preferably, the The liquid epoxy resin is epoxy resin E-51 / 128 produced by Guangz...

Embodiment 2

[0069] A high-gloss and high-hardness water-based epoxy floor coating, including A component and B component, A component is composed of liquid epoxy resin, multifunctional epoxy resin, hydrophilic modified multifunctional epoxy resin and the second A water-based emulsion prepared from deionized water; component B is composed of water-based epoxy curing agent, second deionized water, pigments and fillers, dispersants, defoamers, leveling agents, anti-scratch additives and colorants composition;

[0070] The A component includes the following raw materials in parts by weight:

[0071]

[0072] The B component includes the following raw materials in parts by weight:

[0073]

[0074] The mixing ratio of the A component and the B component is according to the amount of the epoxy group contained in the A component: the amount of the amino active hydrogen contained in the B component is 0.9:3.3; preferably, the The liquid epoxy resin is epoxy resin E-51 / 128 produced by Guan...

Embodiment 3

[0096] A high-gloss and high-hardness water-based epoxy floor coating, including A component and B component, A component is composed of liquid epoxy resin, multifunctional epoxy resin, hydrophilic modified multifunctional epoxy resin and the second A water-based emulsion prepared from deionized water; component B is composed of water-based epoxy curing agent, second deionized water, pigments and fillers, dispersants, defoamers, leveling agents, anti-scratch additives and colorants composition;

[0097] The A component includes the following raw materials in parts by weight:

[0098]

[0099] The B component includes the following raw materials in parts by weight:

[0100]

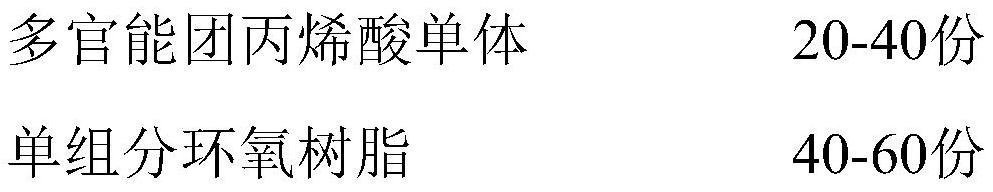

[0101]

[0102] The mixing ratio of the A component and the B component is according to the amount of the epoxy group contained in the A component: the amount of the amino active hydrogen contained in the B component is 1.0:3.5; preferably, the liquid The epoxy resin is epoxy resin E-51 / 128 prod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wear resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com