High-efficiency positive-pressure gas turbine

A gas turbine, high-efficiency technology, applied in the direction of gas turbine devices, combustion air/combustion-air treatment, mechanical equipment, etc., can solve the aerodynamic noise and mechanical noise generated by the main body of the gas turbine, affect the normal work of the staff, and the main body of the gas turbine is easily damaged, etc. problems, to achieve the effect of heat insulation, reduce assembly workload, and improve work comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

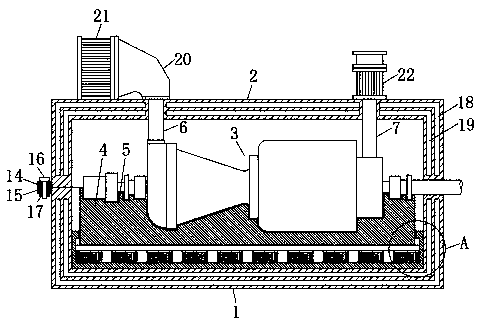

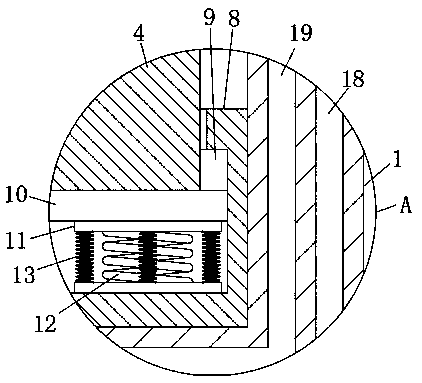

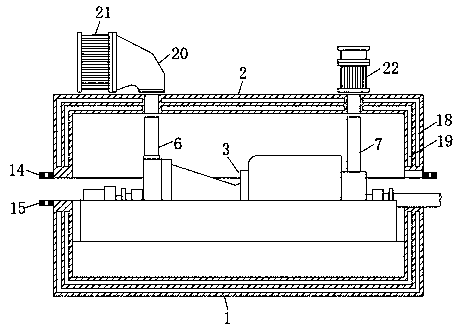

[0027] Reference Figure 1-4 , A high-efficiency positive pressure gas turbine, comprising a gas turbine main body 3 arranged in a lower box body 1 and an upper box body 2, the lower end of the gas turbine body 3 is provided with a mounting seat 4, and the upper end side wall of the mounting seat 4 is provided with The installation groove 5 matched with the lower end side wall of the gas turbine main body 3, during use and installation, first place the gas turbine main body 3 in the lower box body 1, and the gas turbine main body 3 can be placed in the installation groove 5 on the installation seat 4 for installation The groove 5 is matched with the lower end side wall of the gas turbine main body 3. The gas turbine main body 3 has a certain dead weight. The lower end side wall of the gas turbine main body 3 can abut the inner wall of the installation groove 5, and the gas turbine main body 3 can be firmly placed on the installation groove 5. Therefore, the assembly workload of...

Embodiment 2

[0038] Reference Figure 5 The difference between this embodiment and the first embodiment is that an air filter 23 is connected to the end of the intake muffler 21 away from the intake housing 20, and the air filter 23 communicates with the intake muffler 21. The working principle of the cleaner 23 and the connection method with the intake muffler 21 are in the prior art, and will not be described here. The air cleaner 23 can provide clean air for the gas turbine main body 3 to prevent the gas turbine main body 3 from working Inhaling air with impurity particles increases the probability of abrasion and damage, thereby improving work efficiency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com