Modified phenolic resin, preparation method thereof, and modified phenolic resin plate

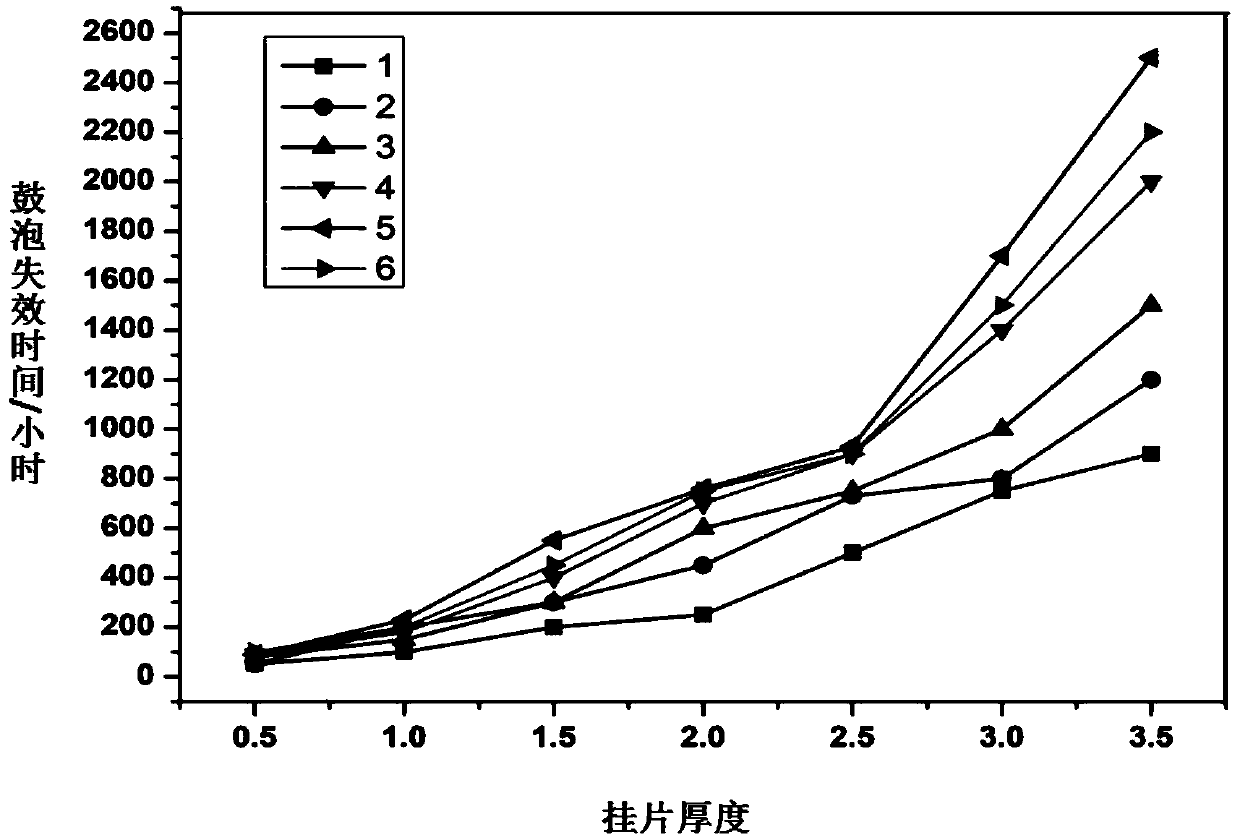

A phenolic resin and modification technology, applied in the field of polymer material modification, can solve the problem that the performance of phenolic resin sheet cannot meet the requirements, and achieve the effects of enhancing comprehensive physical properties, improving impact resistance, and increasing decomposition temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0068] In some examples of the present invention, the preparation method of modified phenolic resin as described above, comprises the steps:

[0069] 1) Contact phenyltrimethoxysilane, methyltrimethoxysilane, basic catalyst potassium carbonate, styrene solvent and water to react in proportion, then add molybdenum compound to the reaction system and stir and mix, preferably stirring time 1 ~2h, obtain silicon molybdenum modifier; In a preferred embodiment, step 1) in phenyltrimethoxysilane, methyltrimethoxysilane, basic catalyst potassium carbonate and styrene solvent and water contact and heat The reaction is carried out under certain conditions, the reaction temperature is 75-90° C., and the heating and reflux time is 12-24 hours.

[0070] 2) Stir and mix the obtained silicon-molybdenum modifier and the nano-montmorillonite-phenolic resin in proportion, preferably stirring and mixing for 0.5 to 1 hour, and then solidify at a temperature of 140 to 160° C., preferably curing fo...

Embodiment 1

[0086] (1) Preparation of silicon-molybdenum modifier: 10 mass parts of phenyltrimethoxysilane, 10 mass parts of methyltrimethoxysilane, 1 mass part of alkaline catalyst potassium carbonate and 20 mass parts of styrene solvent at normal temperature Stir and mix evenly, and slowly add 10 parts by mass of water. After the addition of water is completed, heat up to 80°C and heat to reflux for 20 hours; Stir for 2h to obtain silicon molybdenum modifier.

[0087] (2) Preparation of nano-montmorillonite-phenolic resin solution: add 40 parts by mass of formaldehyde and 20 parts by mass of phenol into a three-necked bottle, add 40 parts by mass of nano-montmorillonite and stir and mix for 1 hour; adjust the pH value of the reaction system by ammonia water Between 7 and 8, heat up to 80°C for reaction. After 1.5 hours of reaction, dehydrate under reduced pressure at 75°C and a vacuum of 8Kpa; after the dehydration amount is stable, prepare a nano-montmorillonite-phenolic resin solution...

Embodiment 2

[0091] (1) Preparation of silicon molybdenum modifier: 15 mass parts of phenyltrimethoxysilane, 5 mass parts of methyltrimethoxysilane, 1 mass part of alkaline catalyst potassium carbonate and 25 mass parts of styrene solvent at normal temperature Stir and mix evenly, and slowly add 15 parts by mass of water. After adding water, raise the temperature to 90°C and heat to reflux for 15 hours; After mixing for 1.5 hours, the silicon molybdenum modifier is obtained.

[0092] (2) Preparation of nano-montmorillonite-phenolic resin solution: Add 50 parts by mass of formaldehyde and 25 parts by mass of phenol into a three-necked bottle, add 25 parts by mass of nano-montmorillonite and stir and mix for 0.5h, adjust the pH value of the reaction system with ammonia water Between 7 and 8, heat up to 90°C for reaction; after 1.5 hours of reaction, dehydrate under reduced pressure at 80°C and a vacuum of 8Kpa, and prepare a nano-montmorillonite-phenolic resin solution after the dehydration ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com