Abrasion-resistant flow guide device

A diversion device and anti-abrasion technology, applied in the direction of damage protection, lighting and heating equipment, heat exchange equipment, etc., can solve the problems of plate abrasion at the entrance of the heat exchanger plate, blockage of foreign objects in the flow channel, etc., to achieve normal protection. Work, prevent flow channel blockage, good diversion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

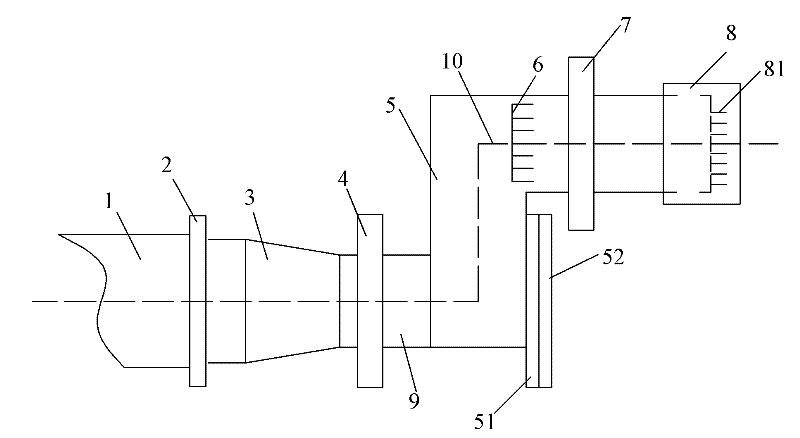

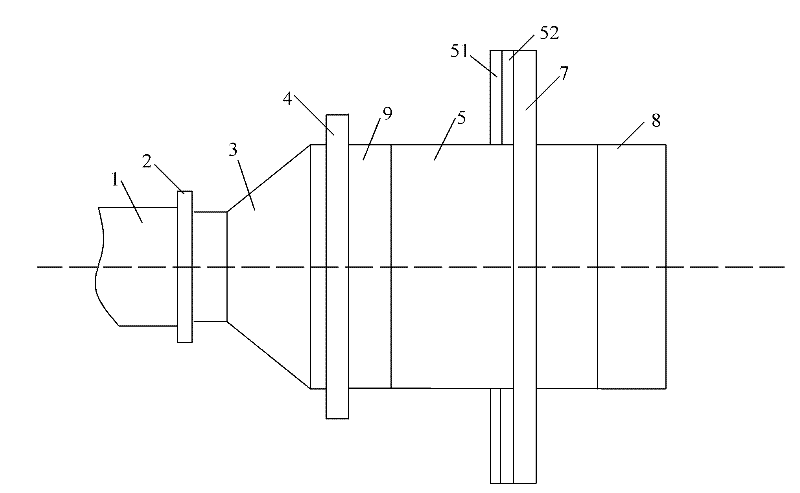

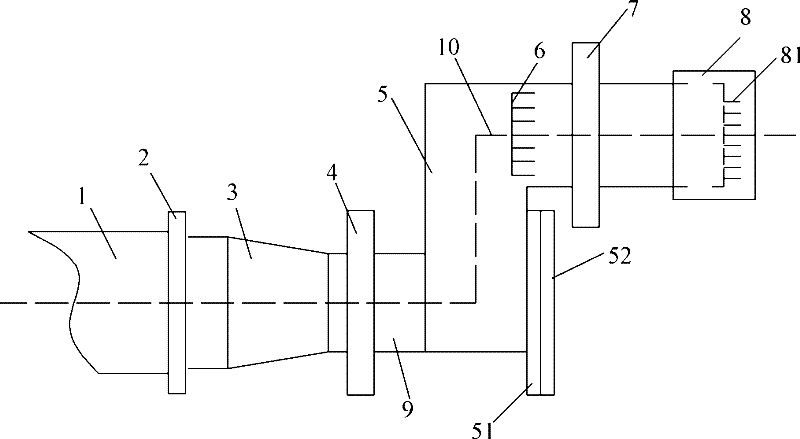

[0025] In order to solve the problem of local abrasion of plates at the entrance of a wide-channel welded plate heat exchanger for solid-liquid two-phase flow after foreign matter and debris in the working medium block the flow channel between the plates, the present invention provides an anti-abrasion flow guiding device, which sequentially includes The inlet flange 2 connected with the system pipeline 1, the "sky round place" buffer distribution channel 3, the second rectangular flange 4, the "Z" type buffer distribution channel 5, the guide vane 6, and the plate with the heat exchanger 8 The first rectangular flange 7 to which the bundle 81 inlet is connected. The cross section of the "Z"-shaped buffer distribution channel 5 is rectangular. The above-mentioned components are connected by known welding. Wherein, the plate bundle is a professional term known to those of ordinary skill in the art, and will not be repeated here.

[0026] In addition, in the present invention,...

Embodiment 2

[0033] The difference between this embodiment 2 and the previous embodiment is that the anti-abrasion flow guiding device provided by the present invention is also provided with a filter device 9 at the entrance of the "Z"-shaped buffer distribution channel 5, and other parts are the same as the previous embodiment. . This embodiment 2 is mainly to solve the problem that foreign matter in the working medium blocks the flow channel.

[0034] The filter device 9 is composed of solid slats. The plate spacing of the solid slats is smaller than the plate spacing of the heat exchanger 8, which can effectively filter out large-sized foreign objects and sundries in the working fluid flow and prevent large particles from blocking the flow channel between the plates. , so as to prevent the abrasion of the plates at the inlet of the heat exchanger from being accelerated due to foreign matter blocking the flow channel between the plates.

[0035] In addition, in order to facilitate the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com