A repair anti-scouring structure and construction method based on tire strip pier

An anti-scour and tire technology, applied in bridge maintenance, bridges, bridge construction, etc., can solve the problems of increased pier size, rust-prone environment, and increased pier flow rate, so as to improve stiffness and bearing capacity, and improve corrosion resistance. , the effect of small influence of overcurrent section

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

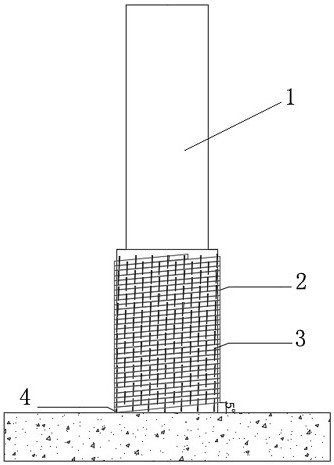

[0029] Example 1, such as figure 1 As shown, an anti-scouring structure based on tire pier repair, including anti-scouring parts sleeved on the lower part of the pile body 1, the anti-scouring parts are as follows from inside to outside: carbon fiber cloth detection layer 2, cement mortar protection layer 3 and tire strip weaving layer 4; carbon fiber cloth detection layer 2 is set on the bottom of pile body 1, and carbon fiber cloth detection layer 2 is provided with cement mortar protection layer 3, the thickness of cement mortar protection layer 3 is 5cm, and cement mortar protection layer 3 is equipped with Tire strip braided layer 4 is arranged.

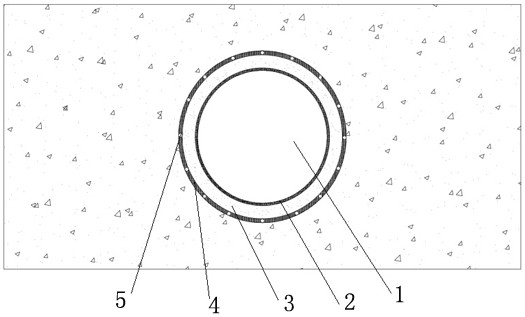

[0030] Such as figure 2 As shown, the carbon fiber cloth detection layer 2 includes the first layer of carbon fiber cloth and the second layer of carbon fiber cloth. After connecting the detection wire, use epoxy resin primer to surround and paste along the first layer of carbon fiber cloth. The high-strength feature of carb...

Embodiment 2

[0032] Embodiment 2, a construction method for repairing the anti-scouring structure based on tire strip pier, the specific steps are as follows:

[0033] Step 1: Clean the damaged part of the pile body, remove mud and rust, and use cement mortar to repair and level the pile body after cleaning to restore the complete shape of the pile body;

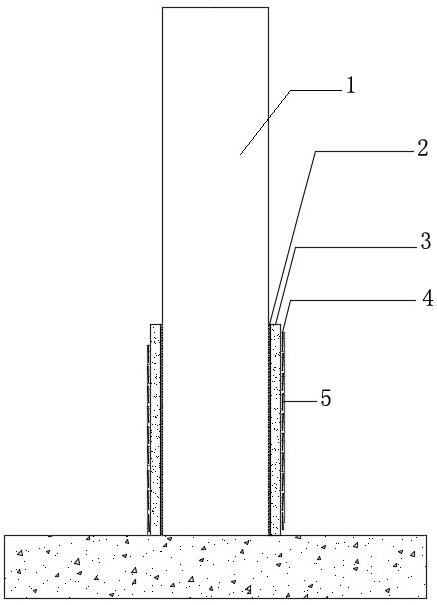

[0034] Step 2: Apply epoxy resin primer around the damaged part of the pile body, surround and paste the first layer of carbon fiber cloth on the damaged part of the pile body, remove the air bubbles of the first layer of carbon fiber cloth with a scraper, and apply the first layer of carbon fiber cloth Two detection wires are bonded to the upper part of the pile to detect the integrity of the pile body after reinforcement;

[0035] Step 3: Apply epoxy primer on the first layer of carbon fiber cloth, surround and paste the second layer of carbon fiber cloth on the first layer of carbon fiber cloth, and stick 3 detection wires on the lowe...

specific example

[0039] Two circular piers of a bridge in Mozigou on the upper reaches of the Minjiang River were damaged under the action of flash floods. Part of the concrete protective layer of the bridge piers fell off, and the steel bars leaked and corroded. The specific construction process is as follows: firstly, clean and remove mud from the gap in the concrete protective layer of the pier, derust the corroded steel bars, repair and level the pier with cement mortar, and restore the shape of the pier; Apply a week of epoxy resin primer in the range, then paste the longitudinal carbon fiber cloth, remove the air bubbles in the longitudinal carbon fiber cloth with a scraper, and bond 2 wires on the upper half of the longitudinal carbon fiber cloth, and continue to apply rings on the outer layer of the longitudinal carbon fiber Oxygen resin primer, and then paste a week of transverse carbon fiber cloth, and bond 3 wires to the lower half of the transverse carbon fiber cloth in the concrete...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com