Multifunctional submersible mixed transportation vortex pump

A multi-functional, swirl pump technology, applied in radial flow pumps, special fluid pumps, pumps, etc., can solve the problems of high temperature resistance, pipeline damage, uneconomical, etc., and achieve strong abrasion resistance and high processing viscosity , the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

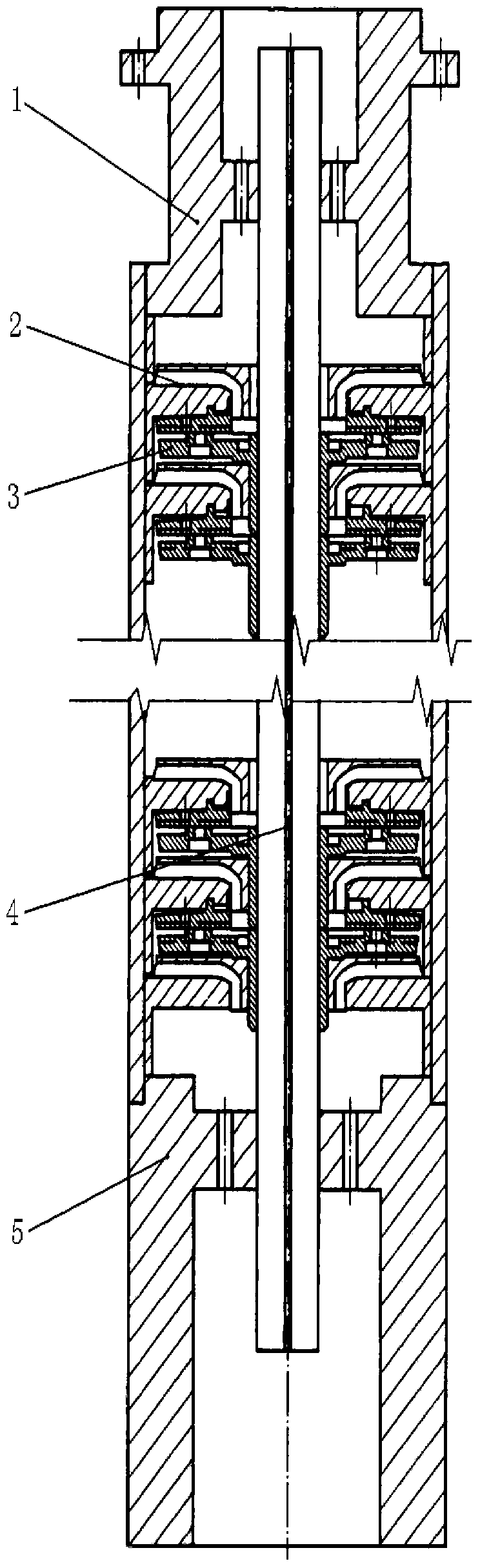

[0019] refer to Figure 1-Figure 3 , a multi-functional submersible mixed transport swirl pump, including a suction port 1, guide impeller 2, swirl impeller 3, pump shaft 4 and discharge head 5. The suction port 1 is connected and installed in sequence with the vane wheel 2, the swirl impeller 3 and the discharge head 5, and the pump shaft 4 runs through the center of the suction port 1, the vane wheel 2, the swirl wheel 3 and the discharge head 5.

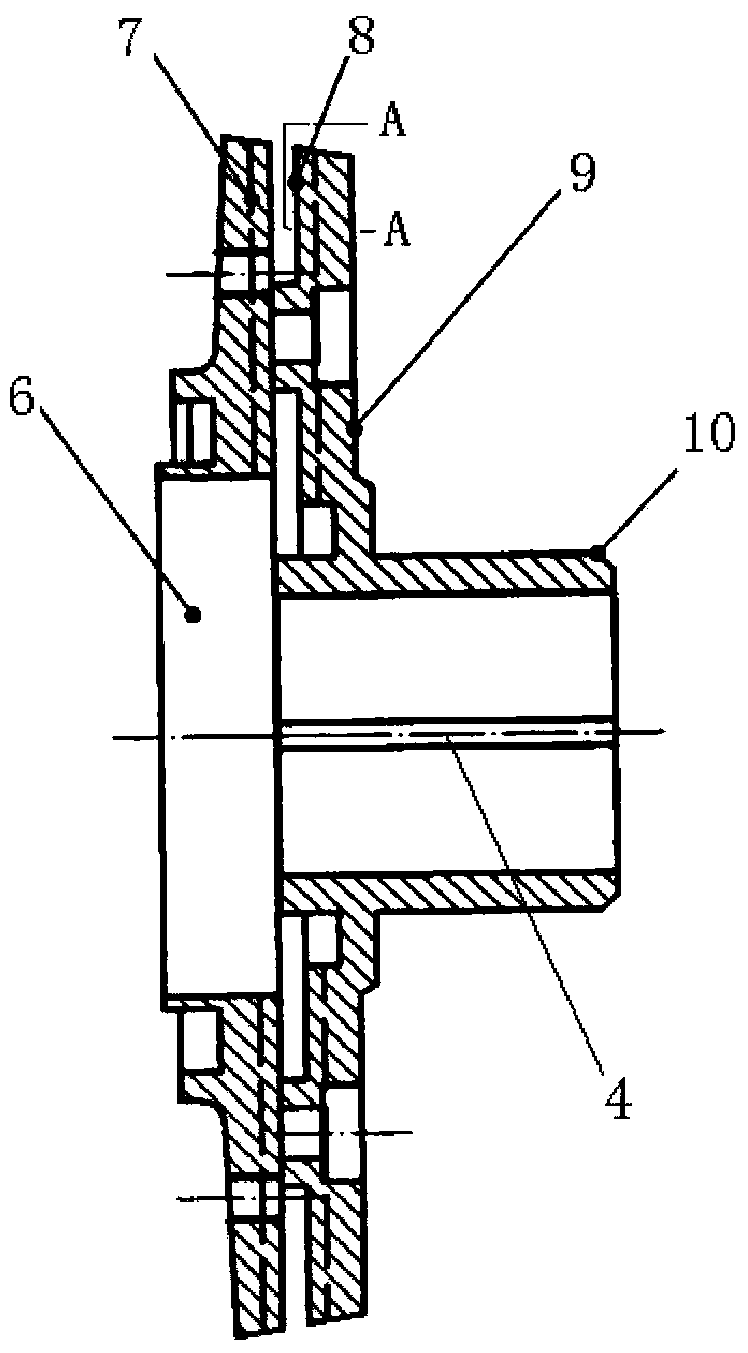

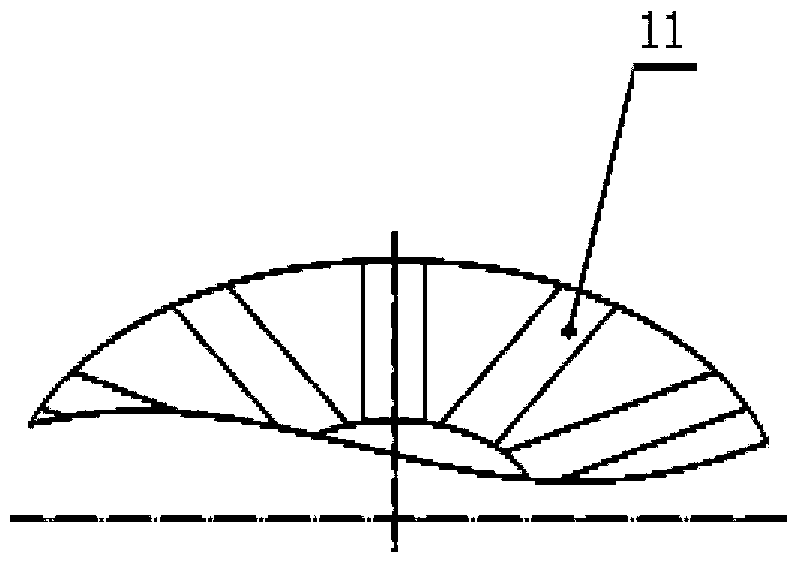

[0020] The swirl impeller 3 comprises an upper cover plate 9 and a lower cover plate 7 installed together, the upper cover plate 9 is equipped with an upper cover plate petiole 10, the lower cover plate 7 is provided with an impeller suction port 6, the upper cover plate 9 and The lower cover plate 7 is respectively provided with 3-16 raised corrugated strips 11, which are shown as 12 in the figure. Between the upper cover plate 9 and the lower cover plate 7 is provided a fluted runner discharge port 8 . There is a gap between t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com