Welding method of 12cr5mo martensitic stainless steel

A martensitic stainless steel, welding method technology, applied in welding medium, welding equipment, welding equipment and other directions, can solve the problems of short service life, the mechanical properties of weld metal can not meet the requirements of petrochemical pipelines, etc., to achieve less spatter, excellent quality Mechanical properties and mechanical properties, good effect of weld formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

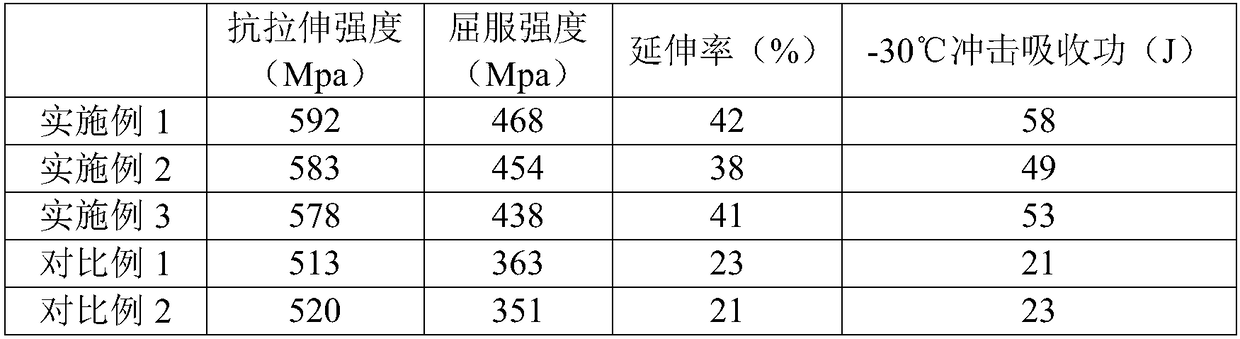

Examples

Embodiment 1

[0069] A welding method for 12Cr5Mo martensitic stainless steel, comprising the following steps:

[0070] Step 1. Prepare the 12Cr5Mo martensitic stainless steel groove, prepare the groove as a Y-shaped groove, the groove angle is 60°, the gap is 2mm, and the blunt edge is 1mm; then the groove is butted and assembled; and the groove is welded Pre-treatment of the groove: First, use 200-mesh sandpaper to polish the welded part of the groove for 40 seconds, then use 800-mesh sandpaper to polish the welded part for 20 seconds, and then put it in a degreasing agent to remove oil. The temperature of the degreasing agent is 30 ℃ , the degreasing time is 60s, and finally washed with water; the degreasing agent is composed of the following raw materials in parts by weight: 10 parts of sodium phosphate, 10 parts of sodium carbonate, 10 parts of OP-10, 20 parts of sodium silicate; Heating method for preheating, preheating is carried out evenly within the range of 100mm on both sides bas...

Embodiment 2

[0113] A welding method for 12Cr5Mo martensitic stainless steel, comprising the following steps:

[0114]Step 1. Prepare the 12Cr5Mo martensitic stainless steel groove, prepare the groove as a Y-shaped groove, the groove angle is 90°, the gap is 3mm, and the blunt edge is 1.5mm; then the groove is butted and assembled; then the groove is welded Pre-treatment of the groove on the part: first use 400-mesh sandpaper to polish the welded part of the groove for 60 seconds, then use 1000-mesh sandpaper to polish the welded part for 30 seconds, and then put it in a degreaser to remove oil. The temperature of the degreaser is 40 ℃, the degreasing time is 100s, and finally washed with water; the degreasing agent is composed of the following raw materials in parts by weight: 16 parts of sodium phosphate, 12 parts of sodium carbonate, 102 parts of OP-102, and 30 parts of sodium silicate; The flame heating method is used for preheating, and the preheating is carried out evenly within the ...

Embodiment 3

[0156] A welding method for 12Cr5Mo martensitic stainless steel, comprising the following steps:

[0157] Step 1. Prepare the groove of 12Cr5Mo martensitic stainless steel, prepare the groove as a Y-shaped groove, the groove angle is 70°, the gap is 2.5mm, and the blunt edge is 1.2mm; then the groove is butted and assembled; Pre-treatment of the groove on the welded part: first use 300-mesh sandpaper to polish the welded part of the groove for 50 seconds, then use 900-mesh sandpaper to polish the welded part for 25 seconds, and then put it in a degreaser to remove oil. The temperature of the degreaser is 35°C, the degreasing time is 80s, and finally washed with water; the degreasing agent is composed of the following raw materials in parts by weight: 13 parts of sodium phosphate, 11 parts of sodium carbonate, 1.5 parts of OP-10, and 25 parts of sodium silicate; Preheating is carried out by flame heating method, and the preheating is carried out evenly within the range of 150mm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com