Copper-based composite material with high strength, corrosion resistance and abrasion resistance

A copper-based composite material, copper-zinc technology, applied in the field of brass graphene composite material and its preparation, can solve the problem of reducing the current-carrying performance and safety of switches, harming human hematopoiesis and nervous system, reducing mechanical properties and electrical conductivity, etc. problems, to achieve the effect of overcoming cutting performance, improving strength and improving cutting performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

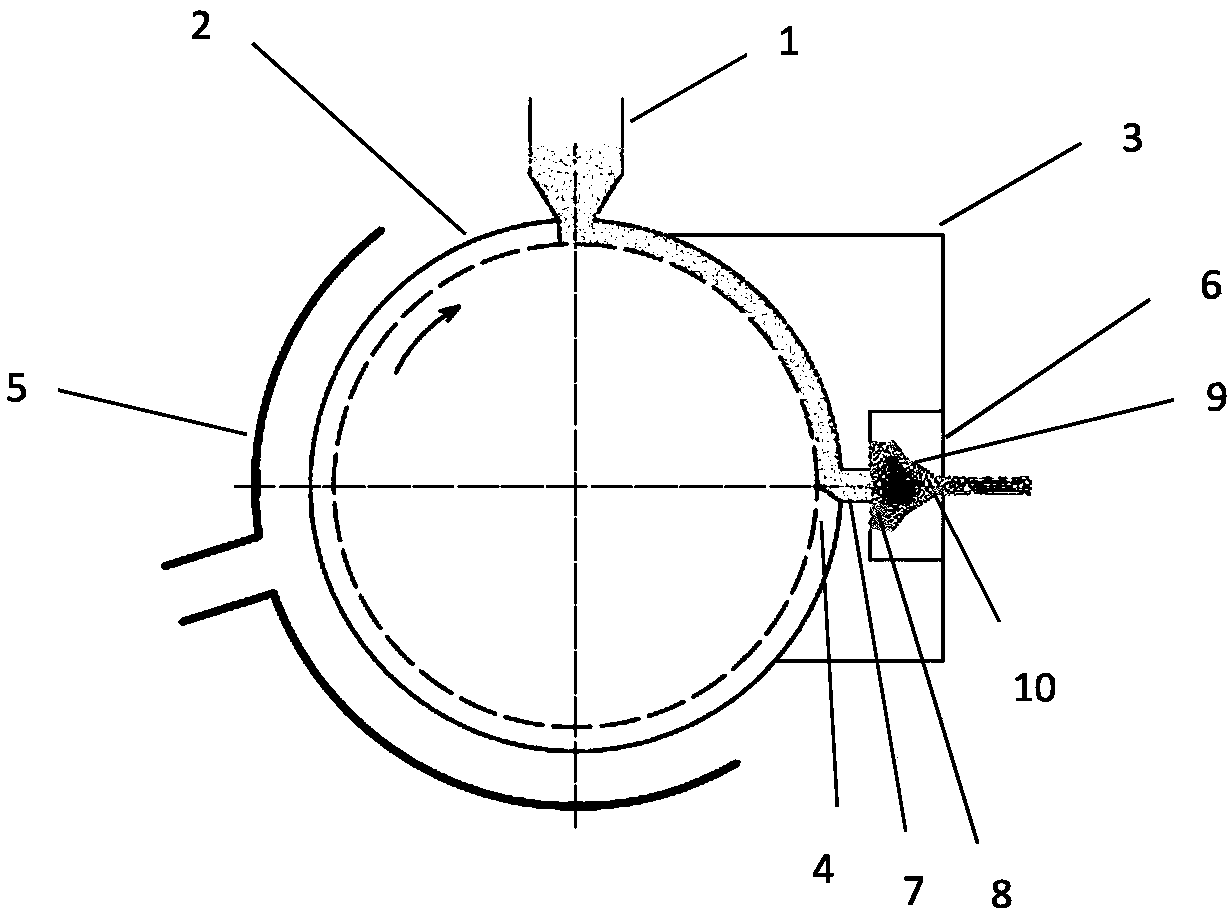

Method used

Image

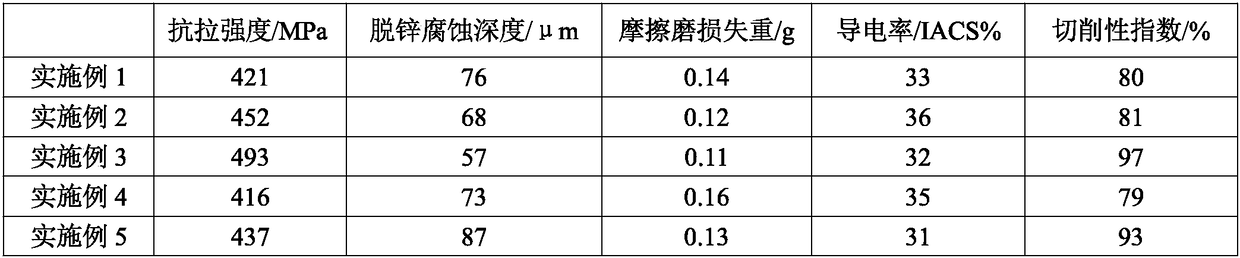

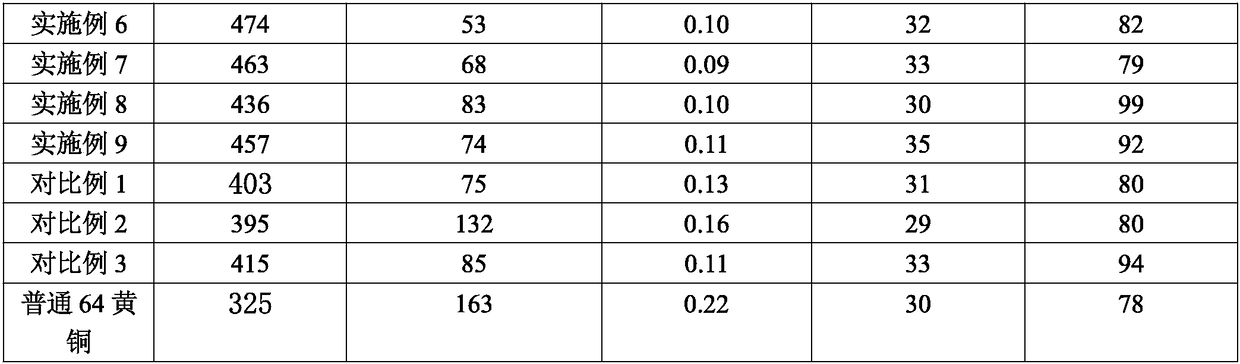

Examples

Embodiment 1

[0038] A wear-resistant brass graphene plate for switch connectors is prepared, the product composition is Cu: 60w%, Zn: 39.97wt%, graphene 0.01wt%, carbon nanotube: 0.01wt%, titanium: 0.01wt%. The raw materials include copper-zinc alloy powder and graphene powder of corresponding composition, carbon nanotube powder and copper-titanium alloy powder. The diameter of copper-zinc alloy powder is 50-200 microns, the diameter of copper-titanium alloy powder is 50-200 microns, the diameter of graphene sheets is 1-50 microns, the diameter of carbon nanotubes is 0.8-2nm, and the length is 5-500 microns. Proportional copper-zinc alloy powder, copper-titanium alloy powder, carbon nanotube powder and graphene powder are mixed with a V-type mixer for 1 hour. After the mixture is even, put the mixed powder into a vacuum-sealed bag for later use. Turn on the electromagnetic induction heater, preheat the rotary wheel to 200°C, use a quantitative pump, put the copper alloy graphene powder int...

Embodiment 2

[0040] A corrosion-resistant brass graphene pipe is prepared, the product composition is Cu: 65w%, Zn: 34wt%, titanium: 0.5%, graphene: 0.5wt%. Raw materials include copper-zinc alloy powder, copper-titanium alloy powder and graphene powder with corresponding components. The diameter of copper-zinc alloy powder is 30-150 microns, the diameter of copper-titanium alloy powder is 50-200 microns, and the diameter of graphene sheet is 1 ~50 microns, weigh the corresponding proportion of copper-zinc alloy powder, copper-titanium alloy powder and graphene powder, and mix them with a V-shaped mixer for 1.5 hours. After the mixture is uniform, put the mixed powder into a vacuum-sealed bag for later use. The rotary wheel does not need to be preheated, the rotary wheel speed is 8rpm, and the brass graphene tube with an inner diameter of 6mm and an outer diameter of 10mm is continuously extruded.

Embodiment 3

[0042] A corrosion-resistant free-cutting brass graphene rod is prepared, the product composition is Cu: 55wt%, Zn: 34.5wt%, titanium: 0.1wt%, graphene: 10wt%, graphite: 0.4wt%. Raw materials include copper-zinc alloy powder, copper-titanium alloy powder, graphene powder and graphite powder with corresponding components. 1 to 30 microns, the diameter of graphite powder is 100 to 500 microns, weigh the corresponding proportion of copper-zinc alloy powder, copper-titanium alloy powder, graphene powder and graphite powder, and use a V-shaped mixer to mix for 2 hours until the mixture is uniform Finally, put the mixed powder into a vacuum-sealed bag for later use. The rotary wheel is preheated to 260° C., and the rotary wheel speed is 12 rpm, and a corrosion-resistant free-cutting brass graphene rod with a diameter of 8 mm is continuously extruded.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com