Anode catalyst slurry, anode catalyst layer, membrane electrode and fuel cell

An anode catalyst layer and catalyst slurry technology, applied in fuel cells, battery electrodes, circuits, etc., can solve problems such as membrane electrode damage, and achieve the effects of avoiding damage, avoiding oxidative corrosion reaction, and low preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

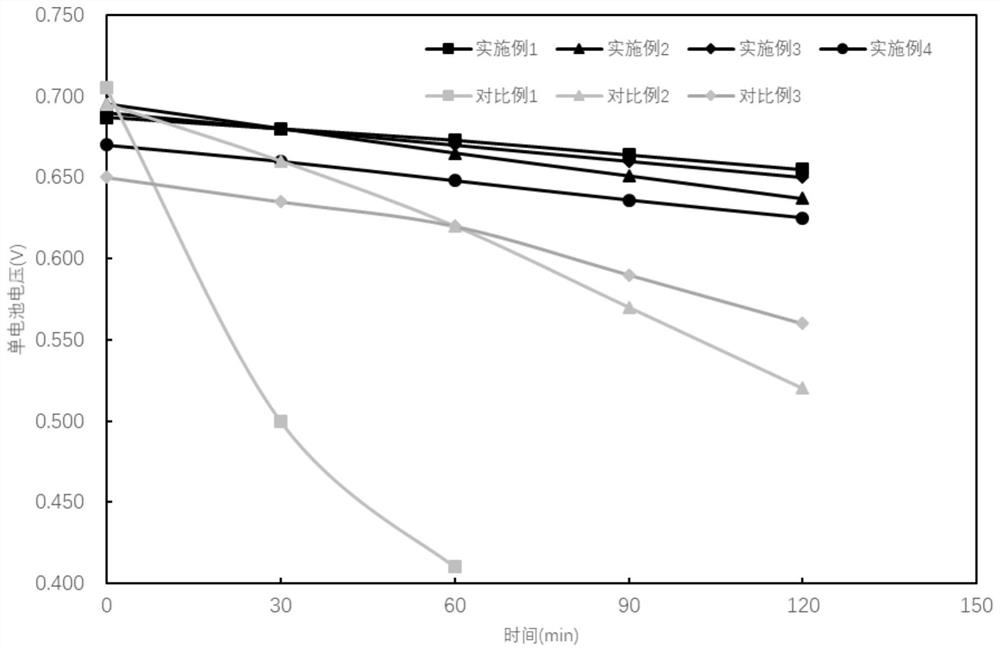

Examples

preparation example Construction

[0045] Here, the preparation method of the above-mentioned anode catalyst slurry includes the following steps: after adding an ionic polymer to the solvent to disperse evenly, adding a carbon-supported noble metal catalyst and an electrolytic water catalyst, and performing ultrasonic (ultrasonic), ball milling, and mechanical shearing (homogeneous) After any one of the dispersing treatments in the mass machine), a homogeneously dispersed catalyst slurry is obtained. The slurry is sprayed or coated on the proton exchange membrane, and dried to obtain the membrane electrode catalyst layer.

[0046] On the other hand, an embodiment of the present invention also provides an anode catalyst layer, wherein the anode catalyst layer contains a carbon-supported noble metal catalyst, an ion polymer, and an electrolytic water catalyst; wherein, the carbon-supported noble metal catalyst includes a carbon support and is supported on The noble metal on the carbon support; the mass of the ele...

Embodiment 1

[0054] Anode catalyst slurry preparation: the Pt / C catalyst with a mass percentage of Pt of 70%, RuO 2 Nano powder, perfluorosulfonic acid ionic polymer solution (5wt% Nafion, Chemours company), and solvent isopropanol were mixed and dispersed by ultrasonic wave to form anode catalyst slurry. Wherein, in the anode catalyst slurry: RuO 2 The nano powder is 80% of the mass of Pt in the Pt / C catalyst, the I / C ratio is 1:1 (the mass ratio of ionomer to carbon support is the I / C ratio), and the solid content is 2wt%.

[0055] Preparation of cathode catalyst slurry: mix Pt / C catalyst with a mass percentage of Pt of 70%, perfluorosulfonic acid ionomer solution (5wt% Nafion, Chemours company), solvent isopropanol, and disperse into cathode catalyst by ultrasonic slurry. Wherein, in the cathode catalyst slurry: the I / C ratio is 1:1, and the solid content is 2wt%.

[0056] Membrane electrode preparation: according to the loading of Pt in the anode catalyst layer is 0.1mg / cm 2 , The ...

Embodiment 2

[0059] The difference between Example 2 and Example 1 is that the preparation steps of the anode catalyst slurry are different, and the rest of the steps are the same. The preparation steps of the anode catalyst slurry in embodiment 2 are as follows:

[0060] Anode catalyst slurry preparation: the Pt / C catalyst with a mass percentage of Pt of 70%, IrO 2 Nano powder, perfluorosulfonic acid ionic polymer solution (5wt% Nafion, Chemours company), and solvent isopropanol were mixed and dispersed by ball milling to form anode catalyst slurry. Wherein, in the anode catalyst slurry: IrO 2 The nano powder is 20% of the mass of Pt in the Pt / C catalyst, the I / C ratio is 1:1, and the solid content is 2wt%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com