Novel anticorrosive coating for grid fitting

A technology for anti-corrosion coatings and power grids, applied in anti-corrosion coatings and other directions, to achieve good economic benefits, excellent performance, and the effect of solving pollution problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

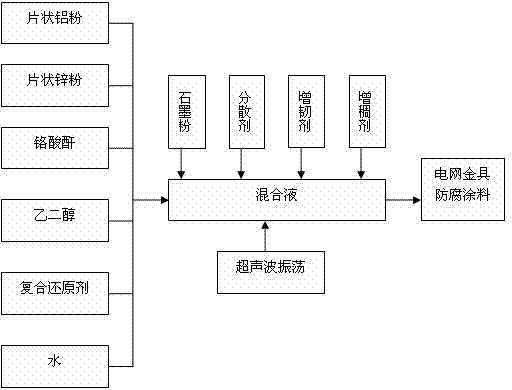

[0020] The specific embodiment of the present invention is as figure 1 As shown, the following is a detailed description of the new anti-corrosion paint coating process for power grid fittings of the present invention.

[0021] The technological process of coating the anti-corrosion paint of the new type power grid fittings in the embodiment of the present invention is as follows:

[0022] Configuration of the coating solution - degreasing and degreasing of the coating base material - mechanical shot blasting to remove scale - coating - preheating and baking - sintering and solidification - cooling - coating - preheating and baking - sintering and solidification - cooling - inspection.

[0023] 1. Preparation of coating solution

[0024] The preparation of the coating solution is different from the general multi-component coatings, which can be mixed and dispersed in proportion. The coating mixing and preparation process is a redox reaction process, so in the coating mixi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com