Surface clad layer treatment method of copper tungsten electrical contact material for arc extinguish chamber

An electrical contact material and processing method technology, applied in metal material coating process, coating, sputtering and other directions, can solve the problem of deterioration of material stability and service life, deterioration of material surface roughness, unfavorable industrial production, etc. The problem is to improve the selective concentrated ablation of the arc, improve the strong hardness and arc resistance, and improve the abnormal breakdown discharge phenomenon.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A method for treating the surface of a copper-tungsten electric contact material for an arc extinguishing chamber, comprising the following steps:

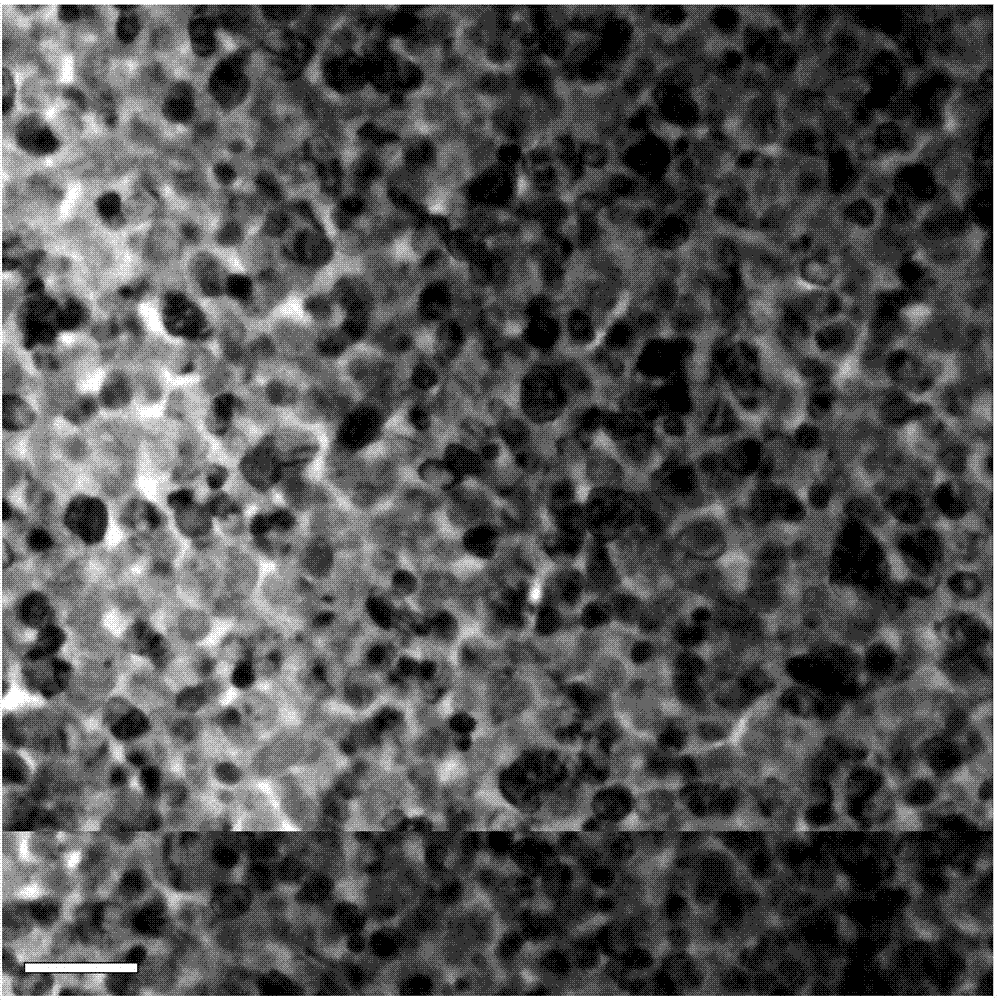

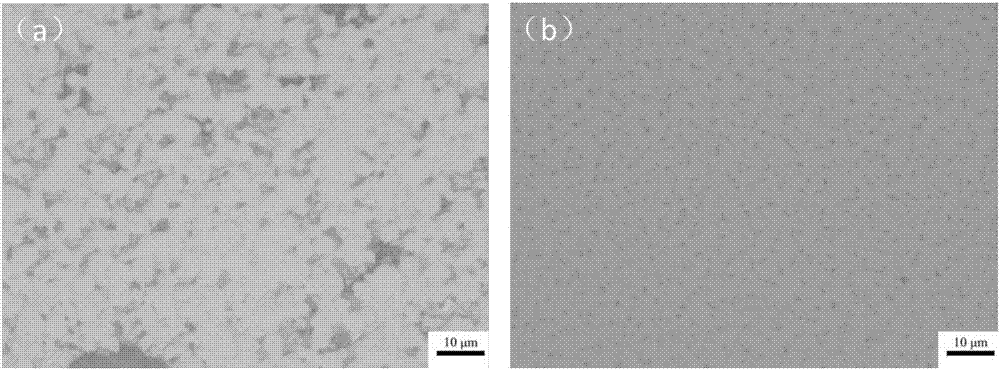

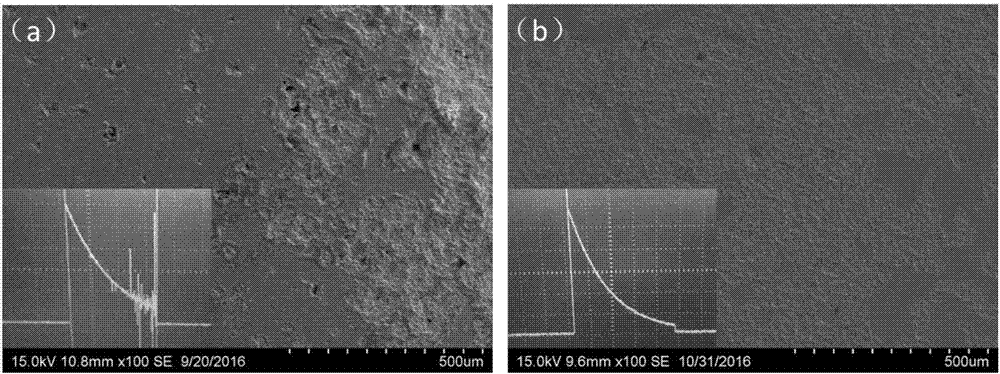

[0033]The CuW60 electrical contact material with a density of 92% prepared by the infiltration method was selected as the base material. After the CuW60 contact material was mechanically polished to a surface roughness of about 0.5 μm, it was placed in an alcohol solution for ultrasonication for 10 minutes, and then Put it in acetone solution and ultrasonically clean it for 10 minutes, and finally rinse it with deionized water and dry it with a hair dryer; then place the CuW60 substrate on a special fixture and fix it on the sample stage in the magnetron sputtering vacuum chamber , put into copper target, tungsten target and chromium target, let the base surface of the contact material be paralleled downward, and place it at 45° with the plane of copper target, tungsten target and chromium target; vacuumize the vacuum cavity...

Embodiment 2

[0035] A method for treating the surface of a copper-tungsten electric contact material for an arc extinguishing chamber, comprising the following steps:

[0036] The CuW80 electrical contact material with a density of 90% prepared by PAS sintering was selected as the base material. After the CuW80 contact material was mechanically polished to a surface roughness of about 0.5 μm, it was placed in an alcohol solution for ultrasonication for 5 minutes, and then Put it in acetone solution and ultrasonically clean it for 5 minutes, and finally rinse it with deionized water and dry it with a hair dryer; then place the CuW80 substrate on a special fixture and fix it on the sample stage in the magnetron sputtering vacuum chamber , put copper target, tungsten target and titanium target, make the base surface of the contact material parallel downward, and place it at 45° to the plane of copper target, tungsten target and titanium target; vacuumize the vacuum chamber to make the chamber ...

Embodiment 3

[0038] A method for treating the surface of a copper-tungsten electric contact material for an arc extinguishing chamber, comprising the following steps:

[0039] The CuW90 electrical contact material with a density of 93% prepared by the infiltration method was selected as the base material. After the CuW90 contact material was mechanically polished to a surface roughness of about 0.5 μm, it was placed in an alcohol solution for ultrasonication for 10 minutes, and then Put it in acetone solution and ultrasonically clean it for 10 minutes, and finally rinse it with deionized water and dry it with a hair dryer; then place the CuW90 substrate on a special fixture and fix it on the sample stage in the magnetron sputtering vacuum chamber , put copper target, tungsten target and nickel target, make the base surface of the contact material parallel downward, and place it at 45° with the plane of copper target, tungsten target and nickel target; vacuumize the vacuum chamber to make th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com