Preparing method for Ti3SiC2/Cu composite conductive powder

A technology of composite conductive powder and powder, which is applied in metal processing equipment, liquid chemical plating, transportation and packaging, etc. It can solve the problems of inability to carry out mass production, complex process, high cost, etc., and achieve good chemical stability and process The process is simple and the effect of energy production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0061] The Ti prepared by the preparation method of the present invention 3 SiC 2 / Cu composite conductive powder is mixed with resin, rubber and other insulating substrates in a certain proportion, by adjusting the Ti 3 SiC 2 / Cu composite conductive powder content, can prepare conductive film material with good conductivity; in addition, Ti 3 SiC 2 / Cu composite conductive powder can also be used as conductive filler of electronic paste.

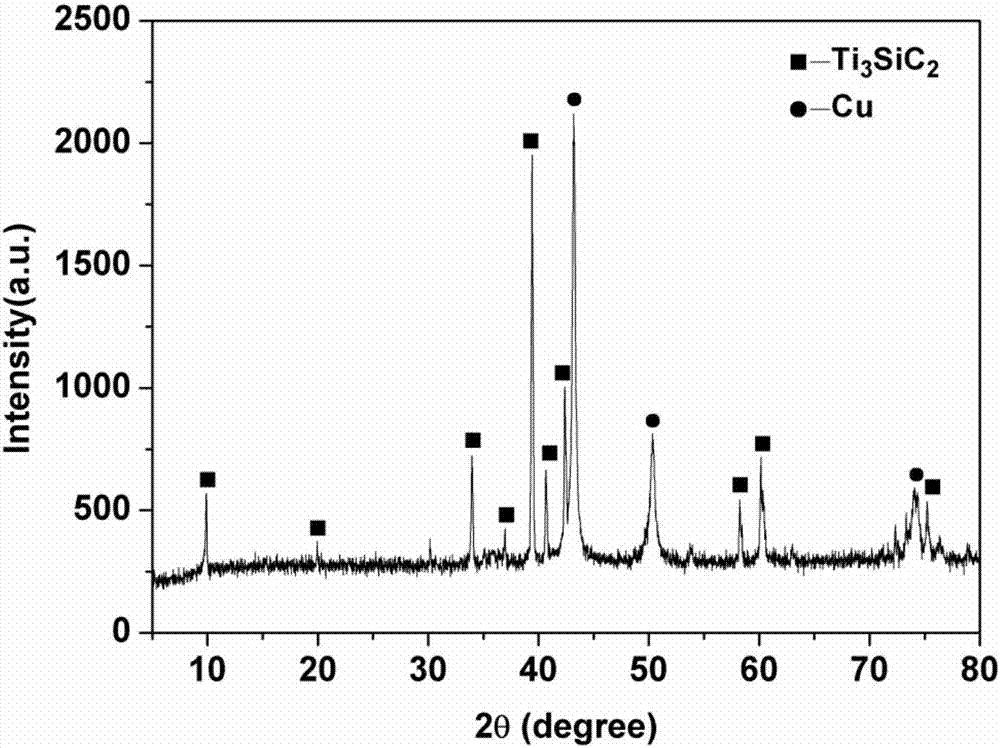

[0062] figure 1 is Ti 3 SiC 2 / Cu composite conductive powder XRD pattern, from figure 1 It can be seen that: except Ti 3 SiC 2 In addition to the diffraction peak of Cu, the diffraction peak of Cu can be clearly observed, indicating that the Ti 3 SiC 2 / Cu composite conductive powder;

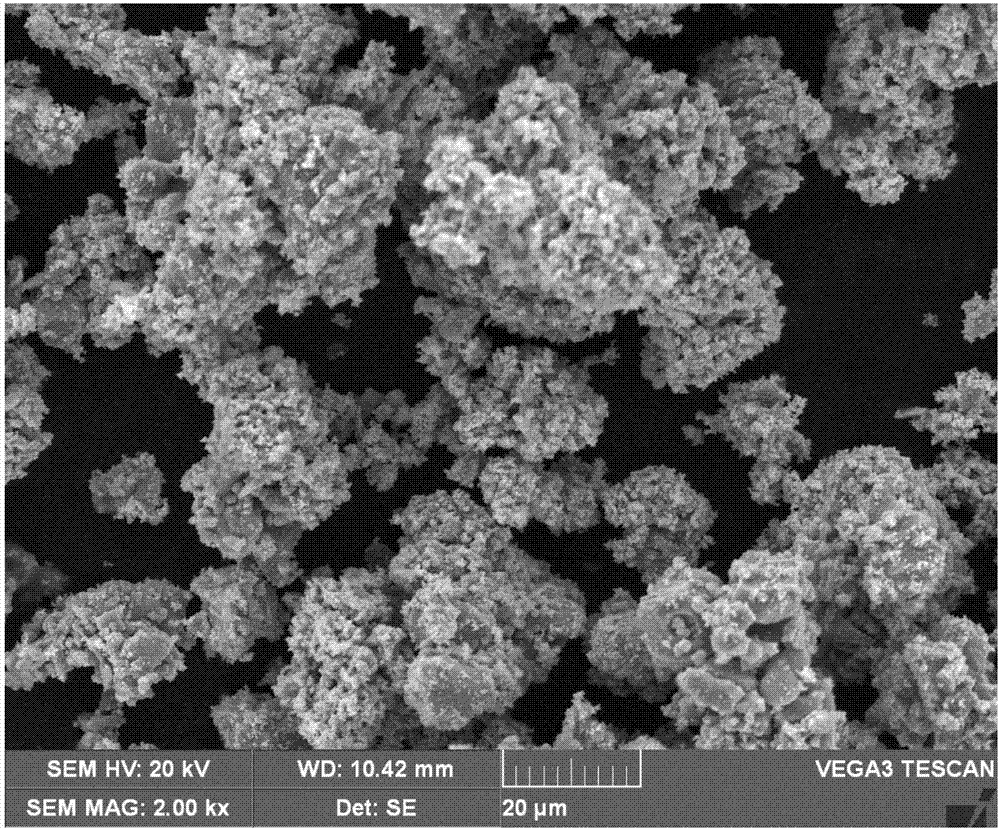

[0063] figure 2 is Ti 3 SiC 2 / Cu composite conductive powder SEM image, from figure 2 It can be seen that the nano-Cu particles are attached to the Ti 3 SiC 2 Powder surface, but not completely covered with Ti 3 SiC 2 Powder.

Embodiment 1

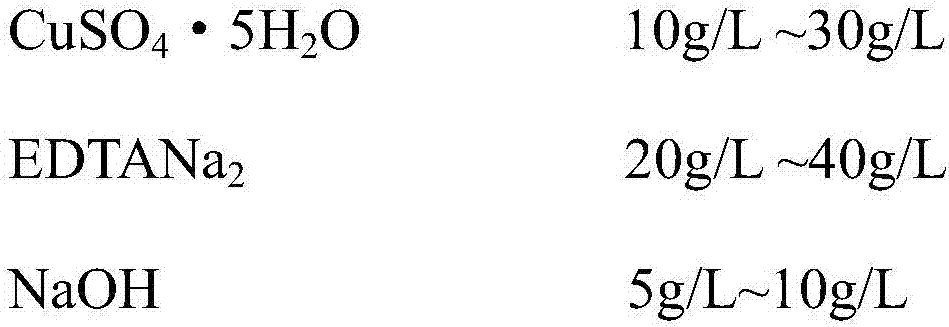

[0065] Take Ti with an average particle size of 2 μm to 20 μm and a purity greater than 93%. 3 SiC 2 powder; the Ti 3 SiC 2 Pour the powder into the ethanol aqueous solution (the ethanol aqueous solution is obtained by mixing ethanol and water at a volume ratio of 1:1), and make the Ti 3 SiC 2 The powder is completely immersed in the ethanol aqueous solution, and the Ti 3 SiC 2 The powder was washed with alcohol, and the alcohol washing time was 10 minutes; the Ti obtained after alcohol washing 3 SiC 2 Pour the powder into hydrofluoric acid aqueous solution (hydrofluoric acid aqueous solution is obtained by mixing hydrofluoric acid and water at a volume ratio of 1:1), and make Ti 3 SiC 2 The powder is completely submerged in hydrofluoric acid aqueous solution, and the Ti 3 SiC 2 The powder is subjected to coarsening treatment, and the coarsening treatment time is 30 minutes; hydrochloric acid (the concentration of hydrochloric acid is 100ml / L) and SnCl are mixed in a...

Embodiment 2

[0072] Take Ti with an average particle size of 2 μm to 20 μm and a purity greater than 93%. 3 SiC 2 powder; the Ti 3 SiC 2 Pour the powder into the ethanol aqueous solution (the ethanol aqueous solution is obtained by mixing ethanol and water at a volume ratio of 1:1.5), and make the Ti 3 SiC 2 The powder is completely immersed in the ethanol aqueous solution, and the Ti 3 SiC 2 The powder was washed with alcohol, and the alcohol washing time was 15 minutes; the Ti obtained after alcohol washing 3 SiC 2 Pour the powder into hydrofluoric acid aqueous solution (hydrofluoric acid aqueous solution is obtained by mixing hydrofluoric acid and water at a volume ratio of 1:2), and make Ti 3 SiC 2 The powder is completely submerged in hydrofluoric acid aqueous solution, and the Ti 3 SiC 2 The powder is subjected to coarsening treatment, and the coarsening treatment time is 40min; the volume ratio is 1:3 with SnCl 2 Aqueous solution (SnCl 2 The concentration of the aqueous ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com