Protective agent composition and corrosion resistant bonding wire and preparation method thereof

A protective agent and composition technology, which is applied in the field of bonding wire, can solve the problems of reducing the reflectivity of metallic silver, the decrease of reflectivity, and the decrease of reaction rate, and achieve the effects of good non-toxicity, environmental protection, easy operation, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

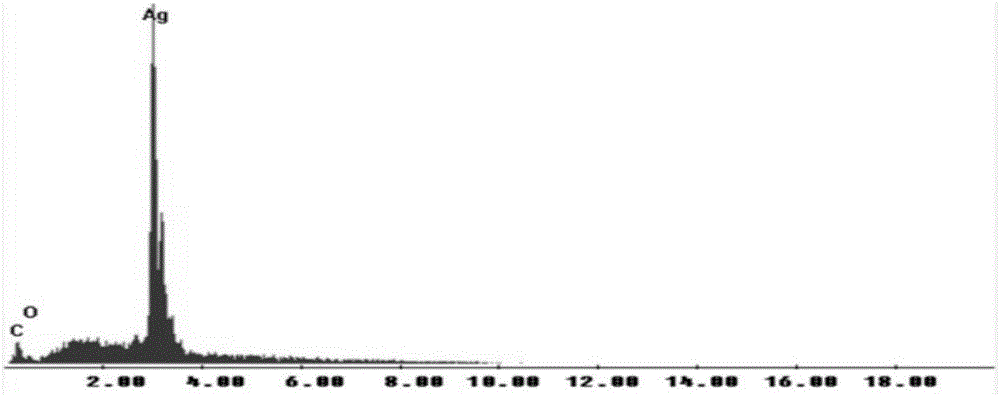

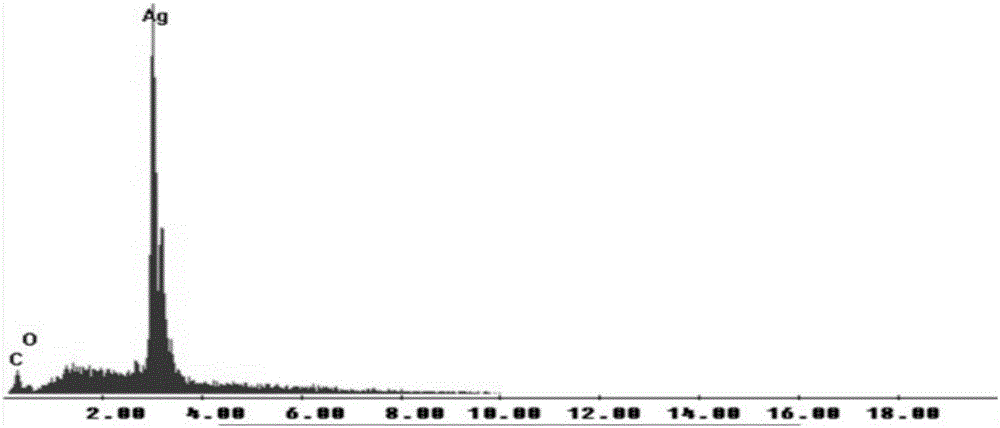

Image

Examples

preparation example Construction

[0035] The present invention has no special limitation on the preparation method of the protective agent composition, as long as the components in the protective agent composition are mixed.

[0036] The invention provides a corrosion-resistant bonding wire, comprising:

[0037] bonding wire;

[0038] A protective film attached to the surface of the bonding wire, the protective film is formed by the protective agent composition described in the above technical solution.

[0039] The present invention has no special limitation on the type of bonding wire, and silver bonding wire, copper bonding wire, aluminum bonding wire, silver-plated gold-plated bonding wire or copper-palladium-plated bonding wire well known to those skilled in the art are used. Can.

[0040] The protective film formed by the protective agent composition provided by the invention is non-toxic and complies with the ROHS standard. After being used for the protection of bonding wires, the corrosion resistanc...

Embodiment 1

[0048] Mix 10 g of picolinate chromium salt, 20 g of sodium chloride conductive salt and 20 g of formic acid solvent to obtain a protective agent composition.

[0049] A silver wire (purity: 99.99%) with a diameter of 360 μm was roughly drawn on a wire drawing machine to obtain a silver bonding wire with a diameter of 80 μm.

[0050] The bonded wire after the rough wire drawing was used as the cathode and immersed in the above protective agent composition at 30°C, the voltage was adjusted to 10V, the passivation time was 2s, and the current density reached 7.5-10A / dm 2 Pass about 3~4C / dm 2 electricity, to obtain corrosion-resistant bonding wires, and then finely drawn to a diameter of 20 μm.

Embodiment 2

[0052] 10g of CrCl 3 Salt, 20g of sodium sulfate and 20g of citric acid solvent were mixed to obtain a protective agent composition.

[0053] A copper wire (purity: 99.99%) with a diameter of 360 μm was drawn on a wire drawing machine to obtain a thick copper bonding wire with a diameter of 80 μm.

[0054] Immerse the above-mentioned bonded wire after coarse wire drawing as a cathode in the above-mentioned protective agent composition at 15°C, adjust the voltage at 30V, and passivation time for 35s. 2 Pass about 4~6C / dm 2 Electricity, to obtain corrosion-resistant bonding wire, and then fine wire drawing to 20μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com