Chip high voltage ceramic dielectric capacitor

A technology of high-voltage ceramics and capacitors, applied in the field of capacitors, can solve the problems of complex process equipment and technology, high industrialization cost, and high sales price, and achieve the effect of large bonding area, large welding area, and firm fixation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present application will be further described in detail below in conjunction with the accompanying drawings and specific preferred embodiments.

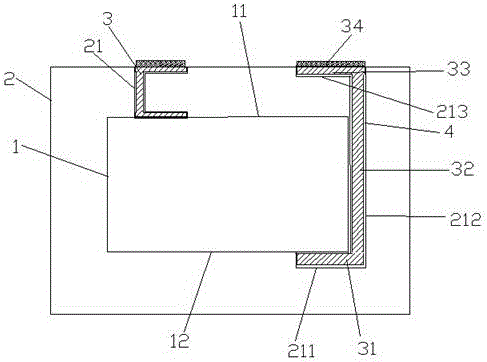

[0021] like figure 1 As shown, a chip-type high-voltage ceramic capacitor, which has a ceramic silver plate 1, a first electrode 11, a second electrode 12, a plastic case 2, a lead groove 21, an electrode horizontal groove 211, a vertical groove 212, and an open horizontal groove 213, metal lead-out wire 3, horizontal welding portion 31, vertical bending portion 32, horizontal bonding portion 33, removable component 34 and liquid insulating sealant 4 and other main technical features.

[0022] A chip-type high-voltage ceramic dielectric capacitor includes a silver ceramic chip, a plastic case, a metal lead-out wire and an insulating sealant.

[0023] The arrangement of the above-mentioned silver ceramic sheets can make the high-voltage chip capacitors into a monolithic shape, the structure is simple, the production proces...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com