Printed circuit board blind hole manufacturing method and structure

A technology for printed circuit boards and manufacturing methods, which is applied in the directions of printed circuit components, electrical connection printed components, and electrical connection formation of printed components, etc., which can solve the problems of high investment requirements, chemical corrosion modification residues, and poor surface smoothness of copper layers, etc. problem, achieve the effect of reducing signal transmission loss, improving surface smoothness, and avoiding drug residue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] An embodiment of the present invention provides a method for manufacturing a blind hole on a printed circuit board, including the following steps:

[0025] Blind holes are opened on the printed circuit boards made with the inner circuit;

[0026] Make organic film on the surface of printed circuit board;

[0027] A connection hole is opened on the organic film at the bottom of the blind hole to expose the inner copper circuit;

[0028] Electroless copper plating is performed on the printed circuit board to form an electroless copper plating layer;

[0029] Electroplating on the electroless copper layer to form hole-filled metal electrodes and outer-layer circuits;

[0030] Etch the unplated electroless copper layer, and press the insulating material on the outer circuit.

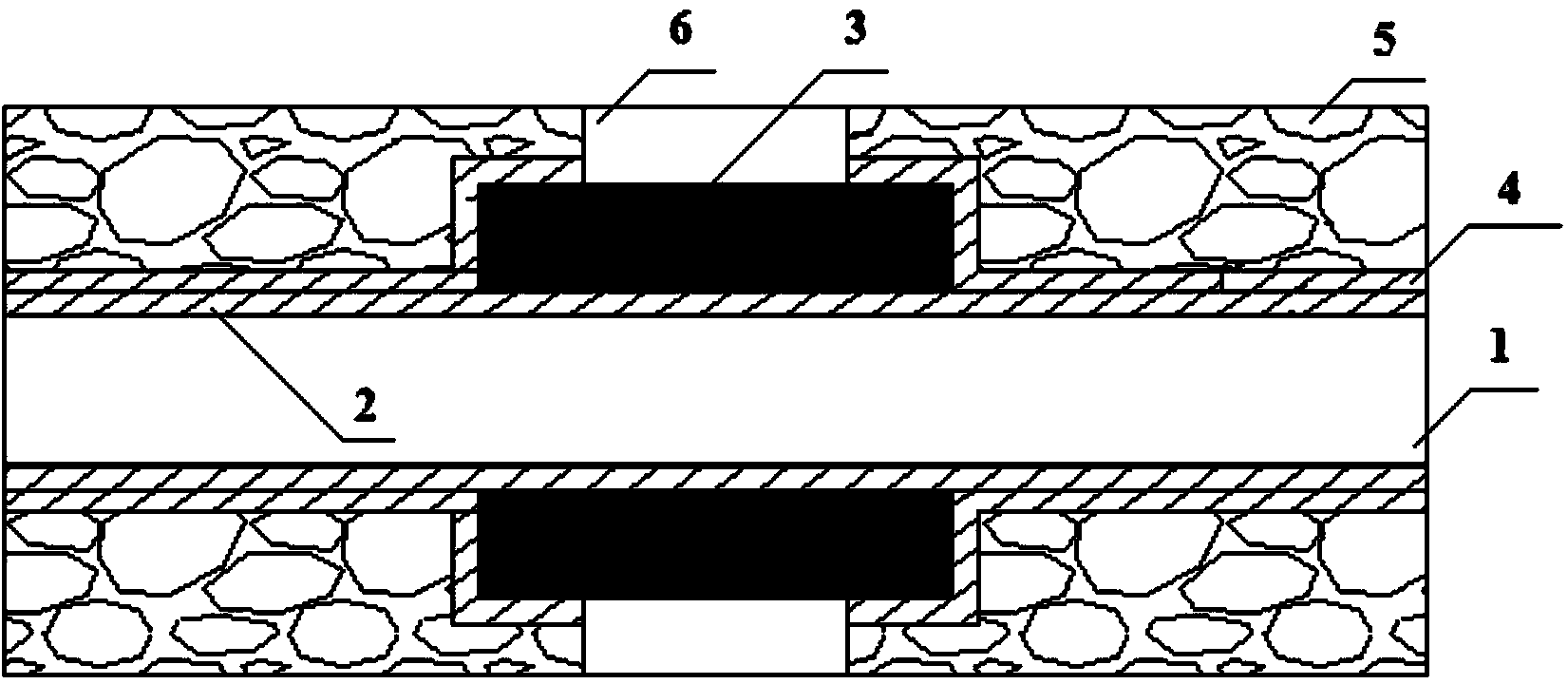

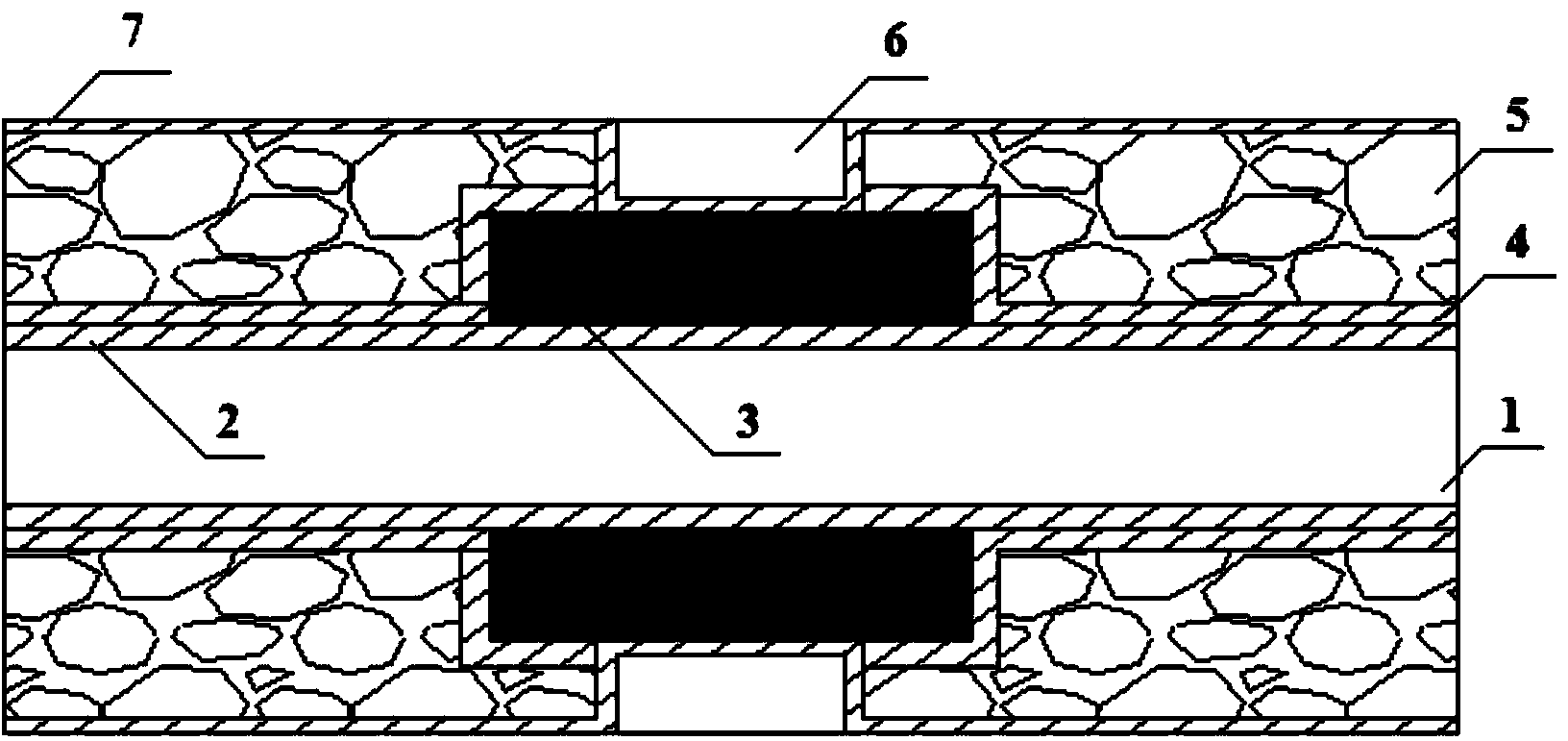

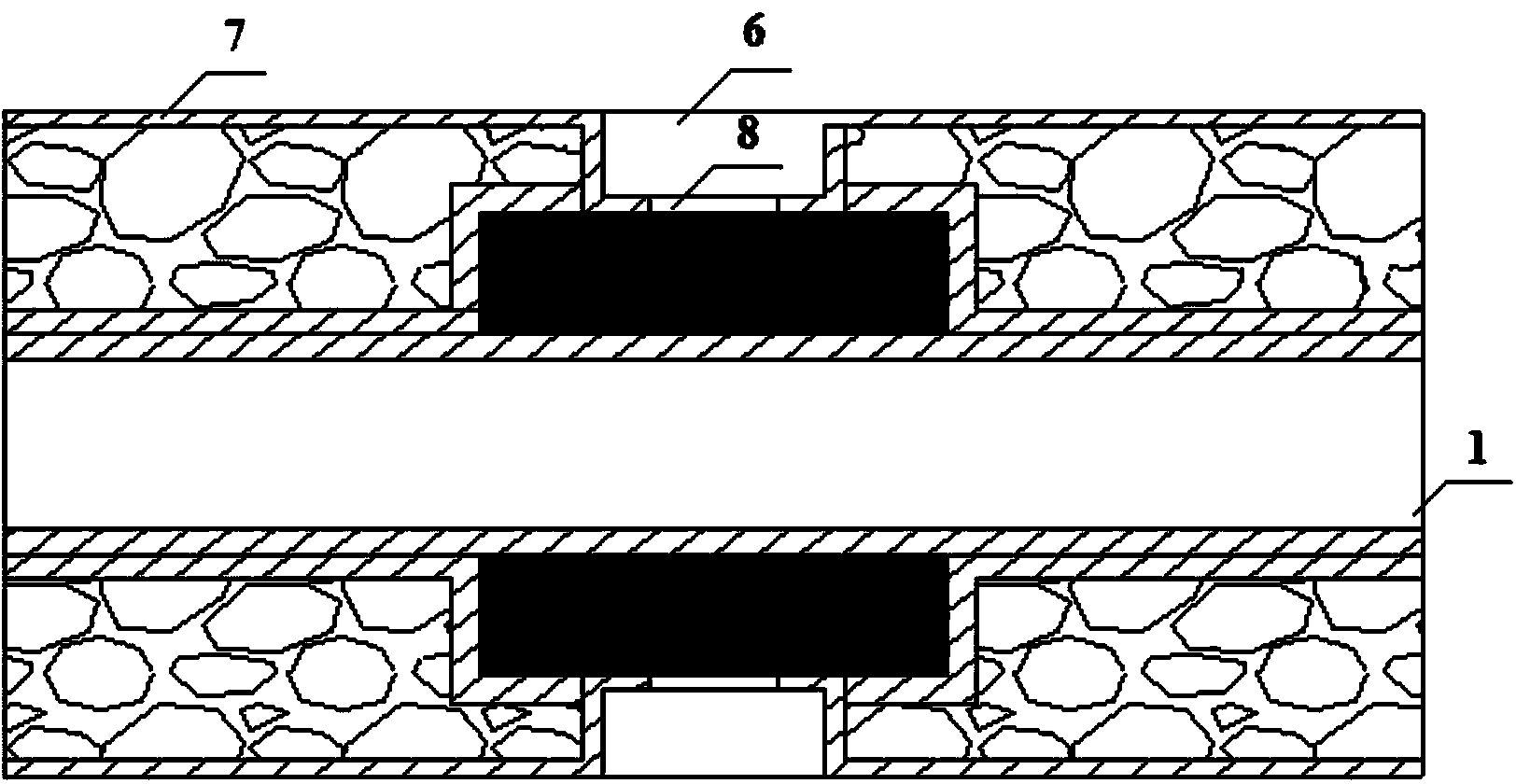

[0031] See figure 1 , The blind hole 6 serves as a channel medium for connecting the multilayer circuit, and penetrates the inner insulating material 5. One end of the blind hole is a partially exposed inner lay...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com