Contact structure for non-vacuum medium, and switch

A non-vacuum, contact technology, applied in the direction of contact surface shape/structure, electrical switch, contacts, etc., can solve the situation that the contact center cannot be observed, the flow capacity between the contacts is weakened, and the number of contact points is reduced. and other problems, to achieve the effect of small contact resistance, smooth and smooth adjustment, and accurate docking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings, which are explanations rather than limitations of the present invention. It should be understood that the present invention is capable of various changes in different embodiments without departing from the scope of the present invention.

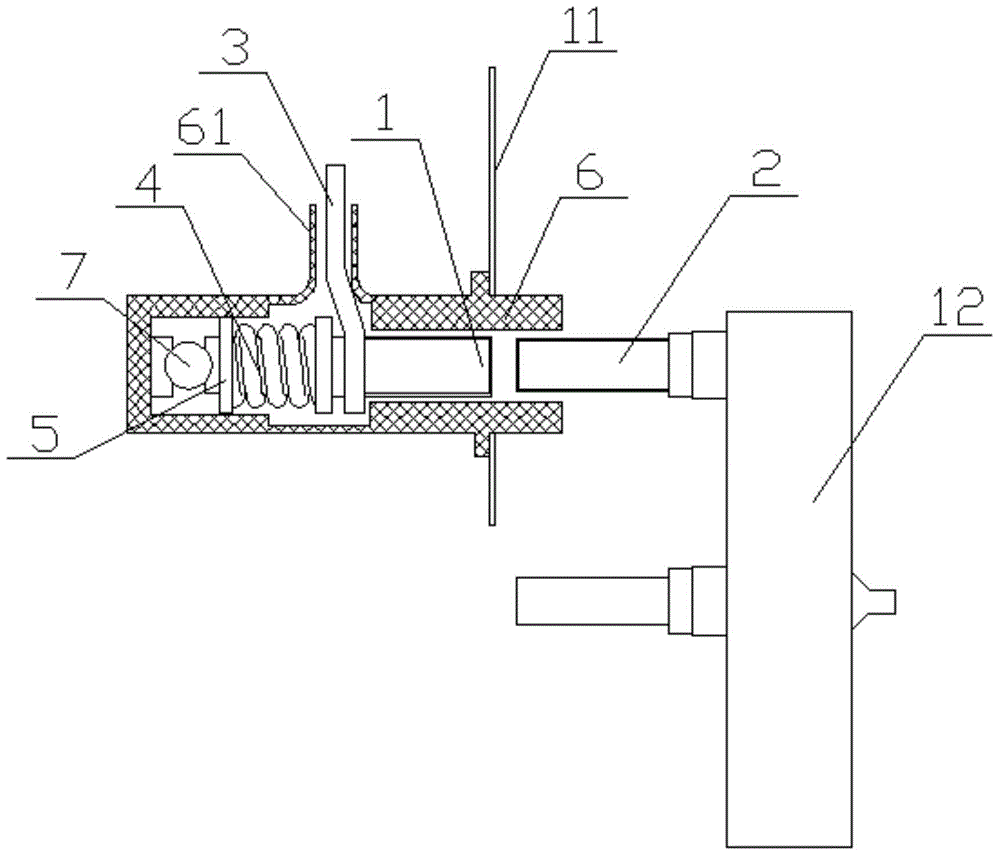

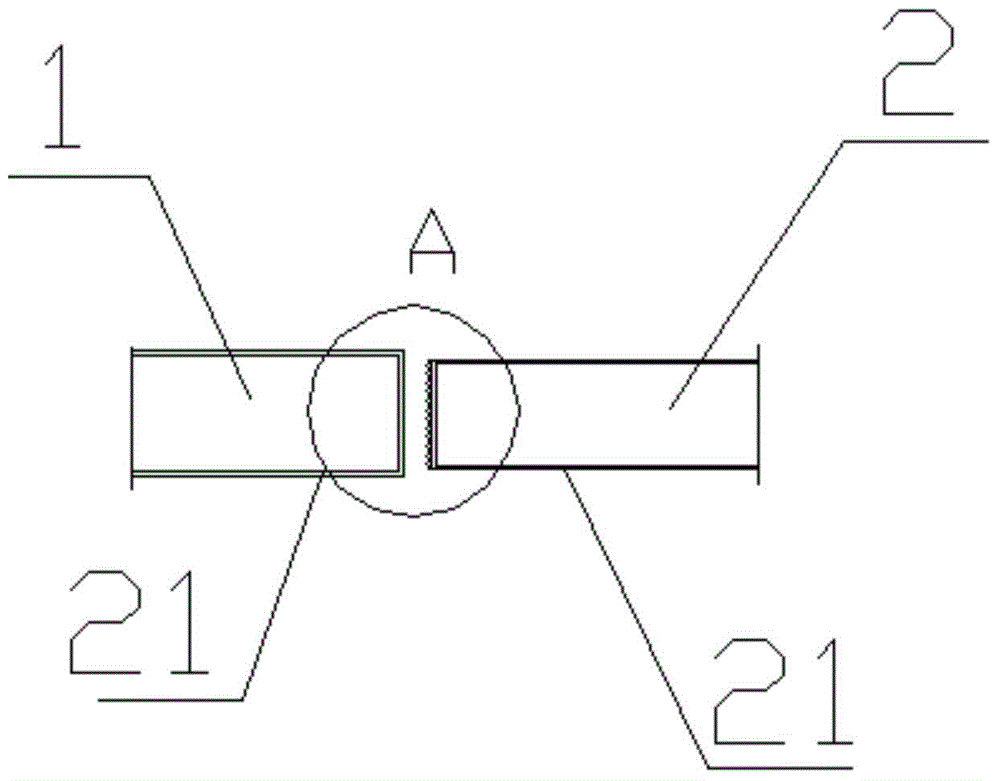

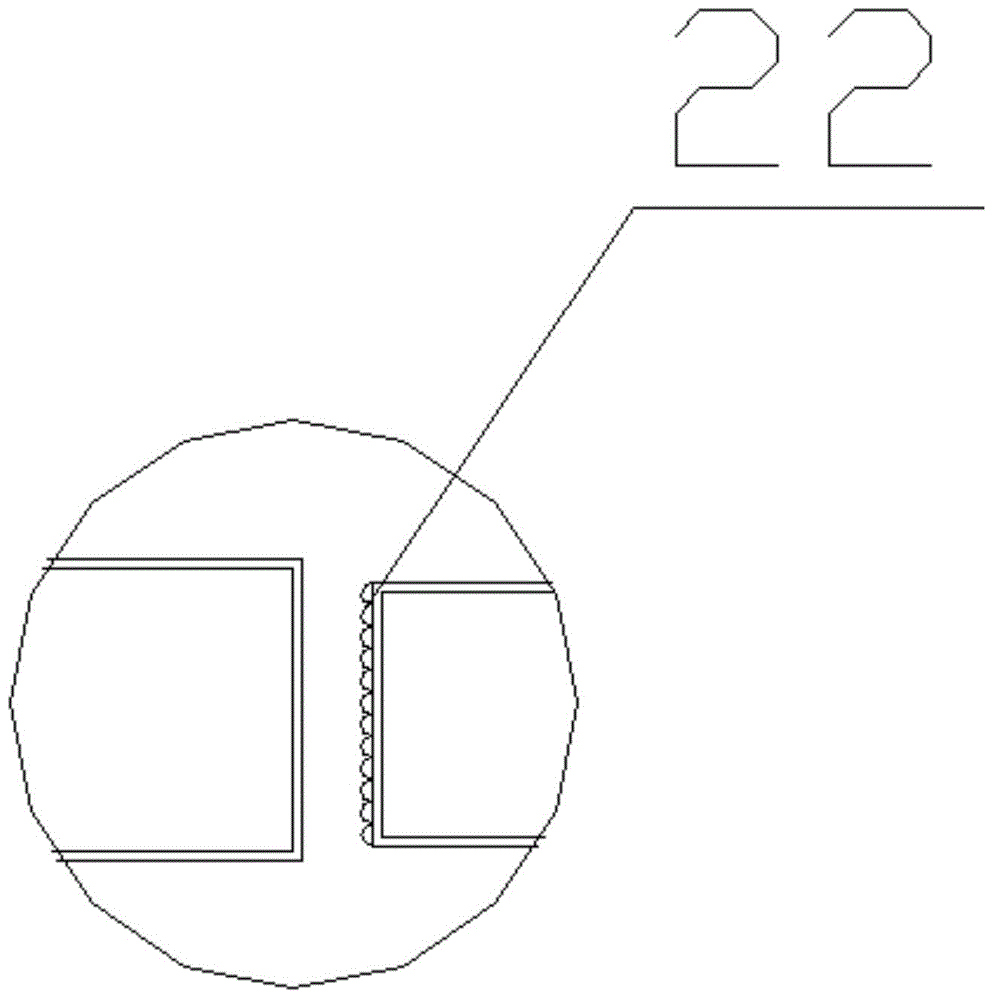

[0028] Such as figure 1 As shown, the present invention is a contact structure for non-vacuum medium, including the first contact 1, the second contact 2, the soft connection 3, the insulating cylinder 6; the first contact 1 and the second contact 2 The contact ends are all arranged in a plane; the insulating cylinder 6 is provided with an end opening part and a middle opening part 61; the contact end of the first contact 1 is located in the end surface of the end opening part of the insulating cylinder 6; the first contact 1 and the second contact The electrical contact of the head 2 forms a flat butt joint, and the contact...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com