A kind of all-solid-state lithium-ion battery composite electrode material and its preparation method and all-solid-state lithium-ion battery

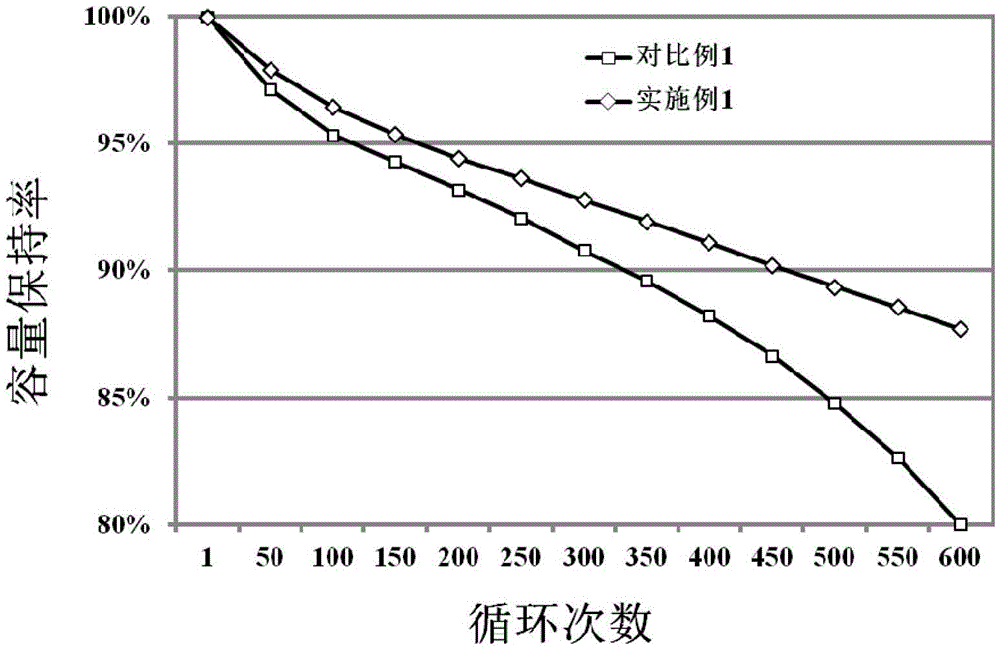

A lithium-ion battery, electrode material technology, applied in battery electrodes, non-aqueous electrolyte battery electrodes, secondary batteries, etc., can solve the problems of low durability and cycle performance, low battery output power, etc., and achieve good durability and cycle. The effect of performance, high output power, good durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0055] In a second aspect, an embodiment of the present invention provides a method for preparing a composite electrode material for an all-solid lithium ion battery, comprising the following steps:

[0056] In parts by weight, take 0.1-20 parts of polymer monomers, 0.1-50 parts of ethylene glycol derivatives, 0.1-10 parts of lithium salts, 0.1-10 parts of polymerization initiators and 50-99.9 parts of plasticizers to prepare To obtain a mixed solution, the polymer monomer is selected from one or more of fluoropolymer monomers, ether polymer monomers, acrylic polymer monomers and acrylonitrile polymer monomers;

[0057] The mixed solution is arranged on the surface of the electrode active material by electrospinning method, electroblown spinning method, liquid phase spraying method or printing method, and the electrode active material is a positive electrode active material or a negative electrode active material, followed by thermal polymerization , electron beam polymerizati...

Embodiment 1

[0076] A preparation method of a composite electrode material for an all-solid-state lithium ion battery, comprising the following steps:

[0077] (1) In parts by weight, take 15 parts of vinylidene fluoride, 20 parts of ethylene glycol monomethacrylate, and 10 parts of lithium tetrafluoroborate LiBF 4 , 5 parts of azobisisobutyronitrile and 50 parts of propylene carbonate were prepared to obtain a mixed solution;

[0078] (2) Connect the mixed solution to the stainless steel needle through a catheter, and spray the mixed solution through the needle at a flow rate of 0.4ml / h, use the electrode active material as the collector, and the vertical distance from the needle is 15cm, and ground at the same time, the The needle tube is connected to a high-voltage generator, and the voltage is adjusted to 15v, that is, the mixed solution is arranged on the surface of the electrode active material by electrospinning, and the electrode active material is lithium cobaltate;

[0079] Then...

Embodiment 2

[0085] A preparation method of a composite electrode material for an all-solid-state lithium ion battery, comprising the following steps:

[0086] (1) In parts by weight, take 15 parts of ethylene oxide, 0.1 part of ethylene glycol dimethacrylate, and 0.1 part of lithium hexafluorophosphate LiPF 6 , 10 parts of benzoyl peroxide, 50 parts of dimethyl carbonate and 0.1 parts of nano-SiO 2 , to prepare a mixed solution;

[0087] (2) The mixed solution is spun with a spinneret with an air nozzle, and the spinning pressure is 5.88×10 5 Pa, the voltage is DC 50kV, that is, the mixed solution is arranged on the surface of the electrode active material by electro-blowing spinning, and the electrode active material is lithium iron phosphate;

[0088] Then volatilize the solvent in the drying oven, initiate polymerization (110W, λ=375nm) under the irradiation of ultraviolet lamp, and the curing temperature is 25°C, that is to form a coating with a thickness of 1000nm on the surface of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com