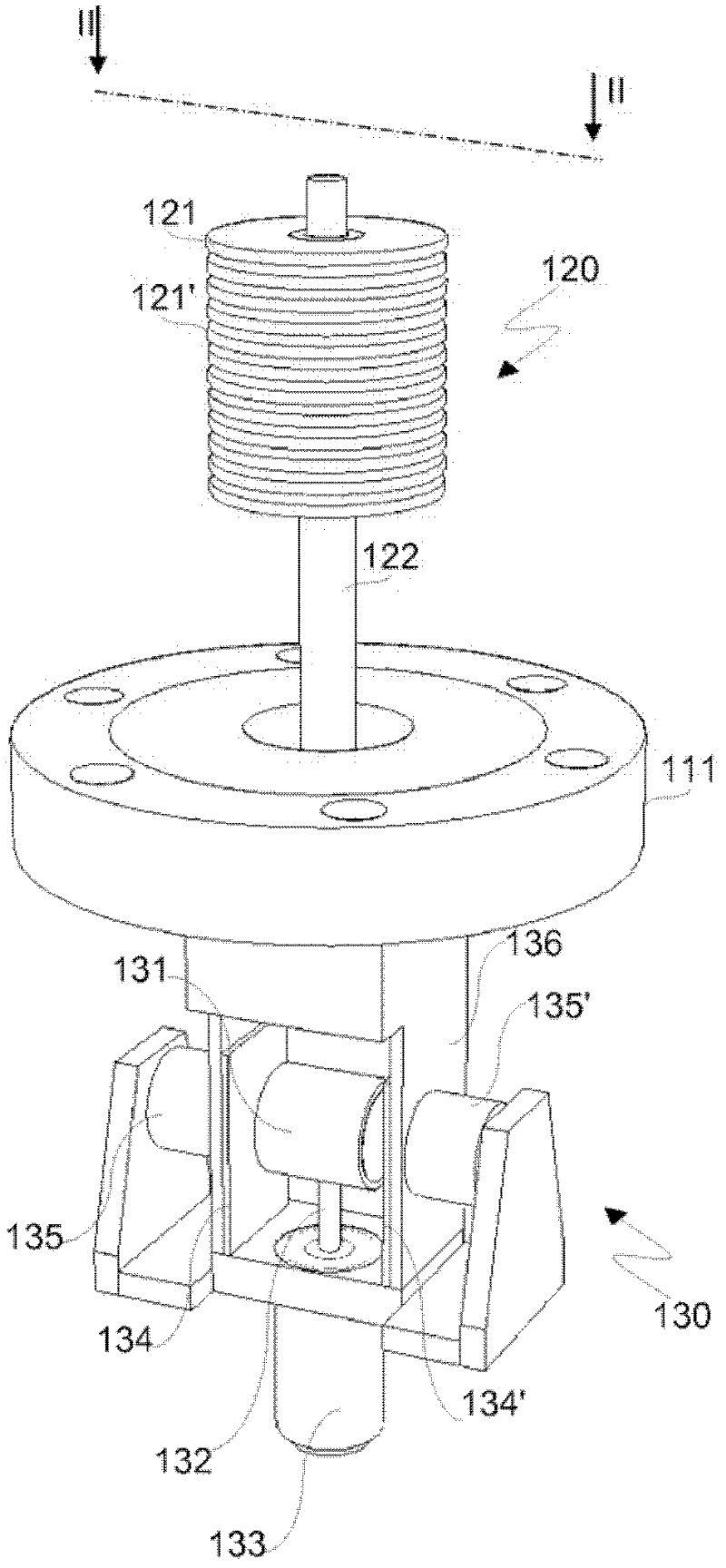

Combined pumping system comprising a getter pump and an ion pump

A technology of suction pump and ion pump, applied in the field of combined pumping system, can solve the problems of reduced gas flow and low conductivity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

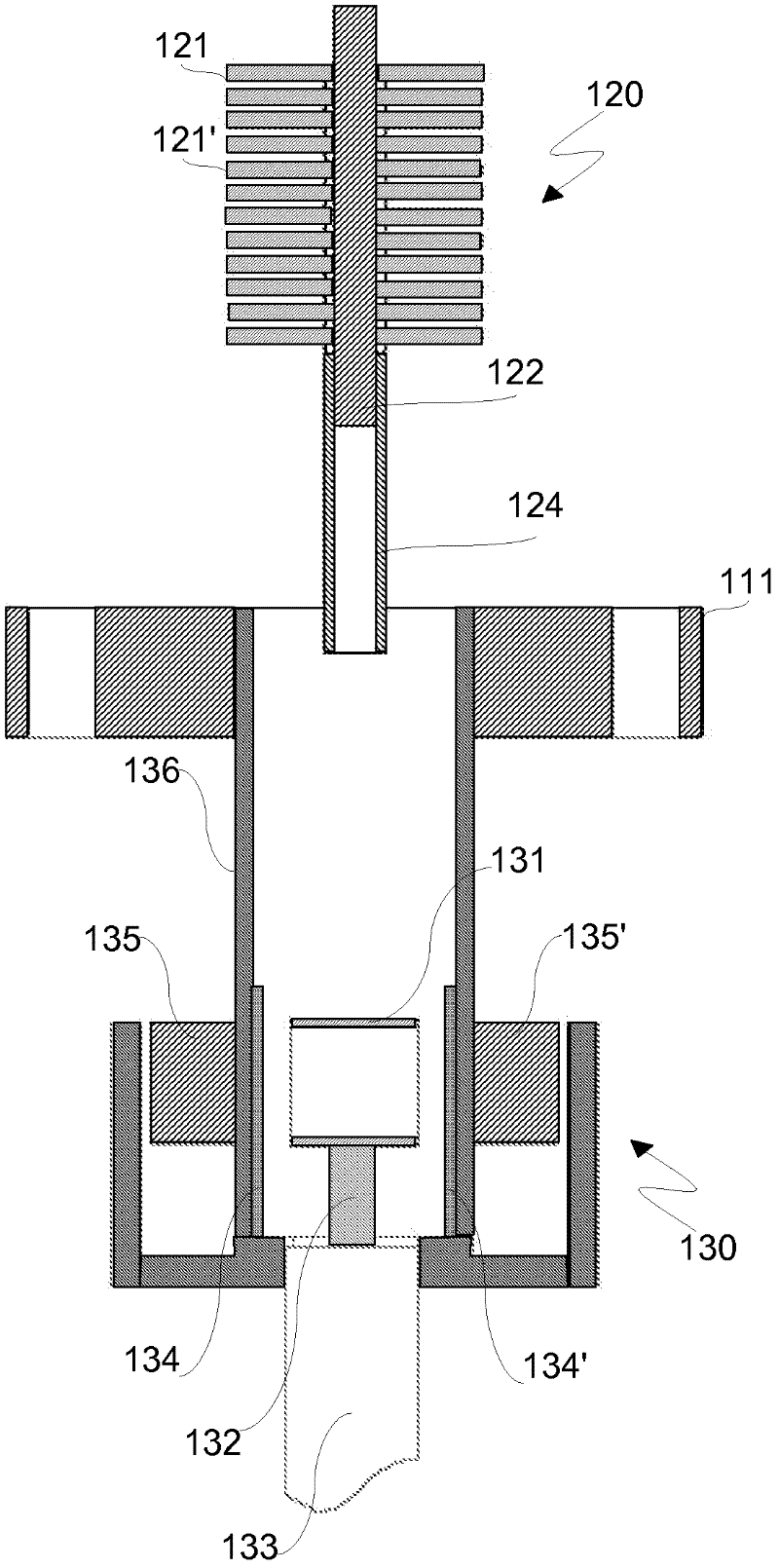

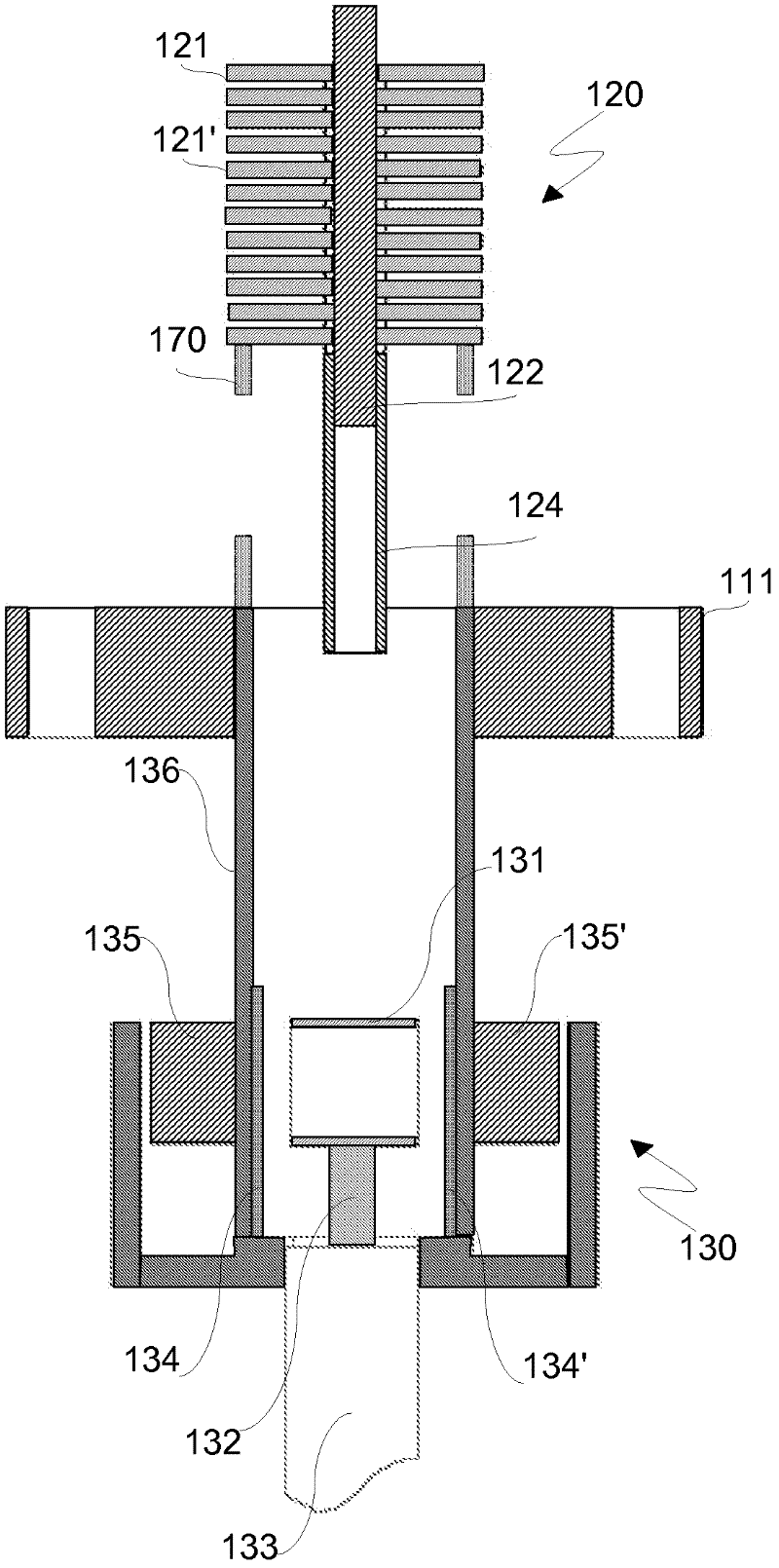

example 1

[0046] A combined pumping system according to a preferred embodiment of the present invention has been prepared, comprising a getter pump model CapaciTorr D-100 manufactured by the applicant and an ion pump with a nominal pumping speed of 2 1 / sec. The pumps have been mounted coaxially with respect to each other and are in accordance with ASTMF798-97 at 2.12 10 -8 kg m 2 s -3 has been tested under constant methane flow conditions. The distance between the flange hole and the aspirator has been fixed at 24mm. Table 1 lists the measured partial pressures for methane and hydrogen chemistries, respectively.

example 2

[0047] Example 2 (as a comparison)

[0048] Under experimental conditions similar to the previous examples, a combined pumping system not according to the invention has been prepared, in which the getter pump and the ion pump have been arranged perpendicular to each other. The volume occupied by the getter pump does not intercept the flange bore axis. The distance between the closest getter pump element and the flange hole connected to the ion pump has been fixed at 38mm.

example 3

[0049] Example 3 (as a comparison)

[0050] Under experimental conditions similar to the previous examples, a combined pumping system not according to the invention was prepared, in which the axes of the getter pump and the ion pump were parallel and about 130 mm apart from each other.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com