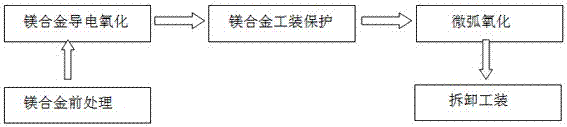

Preparation method of conductive anticorrosive coating on magnesium alloy surface

A kind of conductive anti-corrosion, magnesium alloy technology, applied in the direction of surface reaction electrolytic coating, coating, electrolytic coating, etc., can solve the problems of wear resistance, poor corrosion resistance, brittle and porous, etc., to achieve the effect of improving anti-corrosion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Select an AZ31 magnesium alloy with a size of 50×100×5mm, soak it in absolute ethanol, and ultrasonically clean it for use, and use alkali washing, water washing, and acid leaching to remove oxides on the metal surface and loosely attached cold-worked metal chips and embedded surfaces. Dirt, the formula of alkaline cleaning solution is: Na 2 CO 3 (20g / L), Na 3 PO 4 (18 g / L), Na 2 SiO 3 (10g / L), KOH (1g / L), temperature 50°C, alkali washing time 6min; acid leaching solution is HNO 3 (70g / L), treat at room temperature for 2 minutes.

[0029] After the sample is processed, the oxidation and conductivity process is carried out in the chromate solution. The solution formula is: CrO 3 (4g / L), Na 2 Cr 2 o 7 (3g / L), NaF (0.5g / L), corrosion inhibitor (0.5g / L), treat at room temperature for 10 minutes, take out the magnesium alloy parts, and dry them for later use.

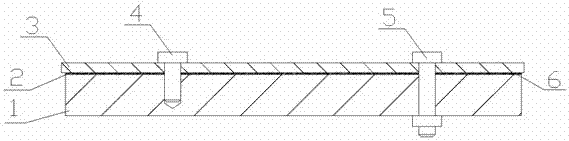

[0030] like figure 2 As shown, the surface 6 on the magnesium alloy part 1 that needs to be assembled a...

Embodiment 2

[0033] Embodiment 2 performance test

[0034] After the AZ31 magnesium alloy material in Example 1 is conductively oxidized, a layer of chemical conversion film is formed on the surface of the material. According to the resistance test, this film has little effect on the conductivity of the magnesium alloy material.

[0035] The corrosion resistance test is carried out by the salt spray test in the environmental test method of military equipment laboratory (GJB150.11A-2009). After the salt spray test, there is no change on the surface of the sample, and the protection effect is good. According to the damp heat test standard in the GJB150.9A-2009 method, the test results meet the product performance requirements.

[0036] It should be noted that the preparation method of the conductive anti-corrosion coating disclosed in the present invention is also applicable to other brands of magnesium alloy materials, such as AZ91 series, AM series, AS series and AE series.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com