Positive pole current collector of lithium ion battery

A cathode current collector, lithium ion battery technology, applied in battery electrodes, electrode carriers/current collectors, circuits, etc., can solve problems such as overall strength decline, pitting corrosion, dissolution of copper ions and nickel ions into the battery, etc. Thermal properties, reduced electrical conductivity, avoidance of wrinkling and breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] According to the composition of the aluminum alloy is Si: 0.4, Fe: 0.42, Cu: 0.08, Mn: 0.6, Ca: 0.06, Sb: 0.01, Ti-B alloy: 0.12, RE: 0.6, the RE is mixed rare earth, La: 20, Ce: 60, Er: 10, Sm: 10, the rest is aluminum and unavoidable impurities for melting, the melting temperature is 750°C, the homogenization treatment is a two-stage homogenization treatment, at 640°C for 12h, at 400°C Insulation for 16 hours; double-stage aging at 100°C for 15 hours, and then at 165°C for 50 minutes. Finally rolled into an aluminum foil with a thickness of 10 microns. The 10-micron aluminum foil and the 2.5-micron-thick aluminum form a three-layer current collector structure.

Embodiment 2

[0022] According to the composition of the aluminum alloy, Si: 0.44, Fe: 0.45, Cu: 0.07, Mn: 0.5, Ca; 0.05, Sb: 0.012, Ti-B alloy: 0.15, RE: 0.5, the RE is mixed rare earth, La: 15, Ce: 60, Er: 15, Sm: 10, the rest are aluminum and unavoidable impurities for smelting, the melting temperature is 760°C; the homogenization treatment is a two-stage homogenization treatment, at 650°C for 10h, at 420°C Insulation for 15 hours; the dual-stage aging is at 110° C. for 12 hours, and then at 175° C. for 45 minutes. Finally rolled into an aluminum foil with a thickness of 8 microns. The 8-micron aluminum foil and the 3-micron-thick aluminum form a three-layer current collector structure.

Embodiment 3

[0024] According to the composition of the aluminum alloy, Si: 0.42, Fe: 0.40, Cu: 0.08, Mn: 0.55, Ca; 0.05, Sb: 0.014, Ti-B alloy: 0.1, RE: 0.45, the RE is mixed rare earth, La: 22, Ce: 58, Er: 10, Sm: 10, the rest is aluminum and unavoidable impurities for melting, the melting temperature is 755°C; the homogenization treatment is a two-stage homogenization treatment, holding at 650°C for 12h, and at 410°C Insulation for 18 hours; the dual-stage aging is at 100° C. for 14 hours, and then at 175° C. for 55 minutes. Finally rolled into an aluminum foil with a thickness of 8 microns. The 8-micron aluminum foil and the aluminum with a thickness of 2.5 microns constitute a three-layer current collector structure.

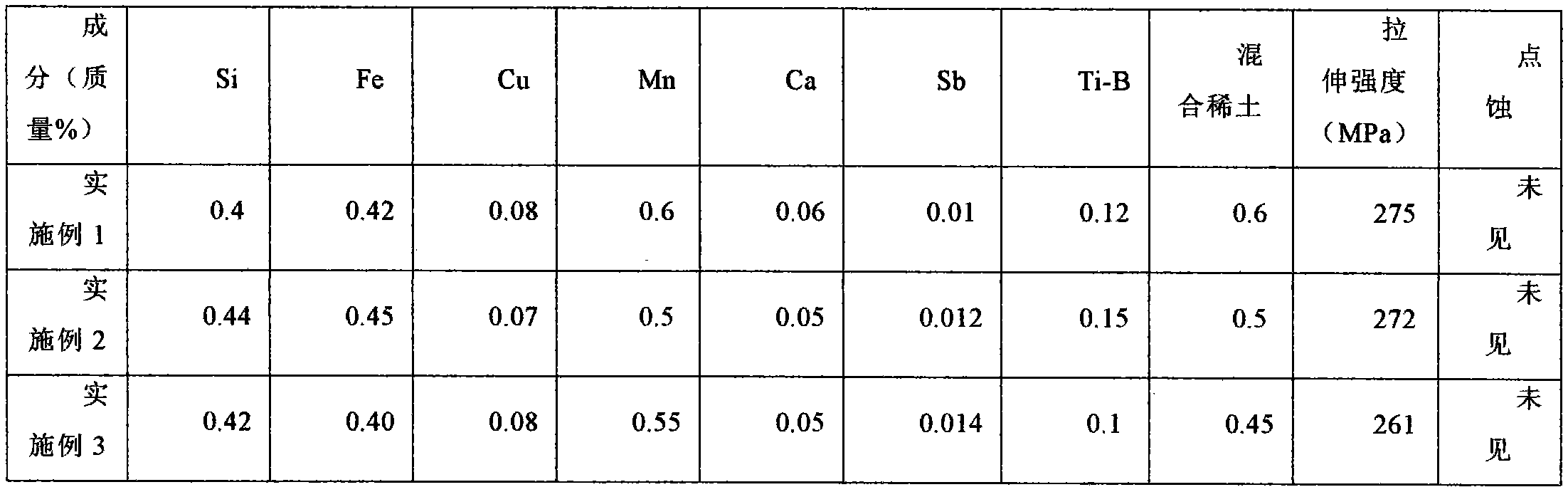

[0025] The composition and performance of table 1 embodiment 1-3

[0026]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com