High-temperature-resisting ferro-bronze and preparing method and application of high-temperature-resisting ferro-bronze

A technology of iron bronze and high temperature resistance, which is applied in the field of high temperature resistant iron bronze alloy and its preparation, can solve the problem of low temperature softening performance of iron bronze, and achieve the effect of excellent high temperature resistance and softening performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described in detail below in conjunction with the embodiments.

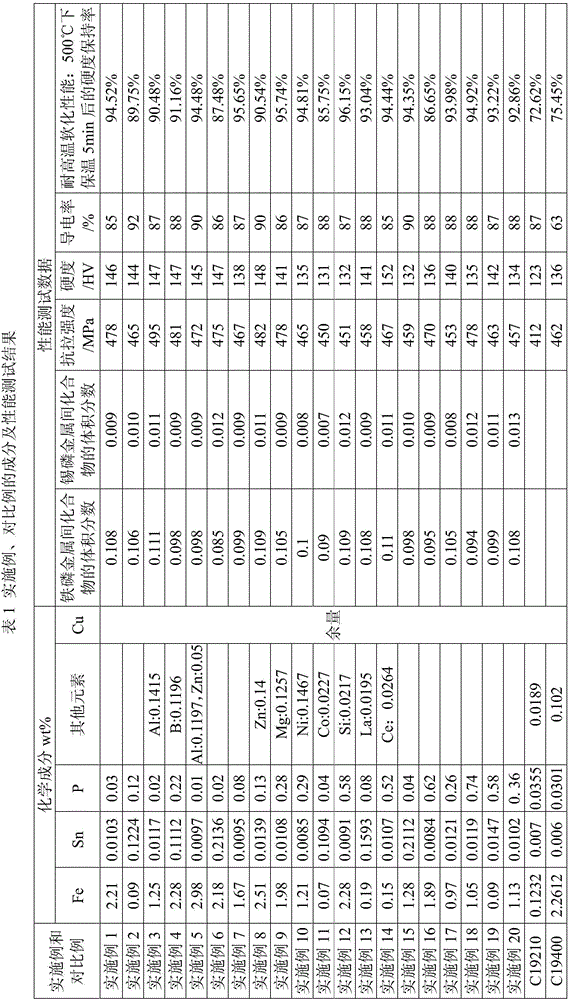

[0036] Twenty example alloys and two comparative alloys (C19210, C19400) were selected and processed into strip products using the same preparation method. The preparation process is: batching → melting and casting → sawing → heating → hot rolling → solid solution and Quenching treatment→face milling→primary cold rolling→primary aging treatment→second cold rolling→second aging treatment→third cold rolling→softening annealing→fourth cold rolling→stretch straightening→finished product, among which, the hot rolling temperature is 900 ~950℃, the holding time is 3~6h; the solution temperature is 600~750℃; the temperature of the primary aging treatment is 500~600℃, and the holding time is 8~9h; the temperature of the second aging treatment is 420~500℃, The holding time is 6-9h. The specific processing technology is:

[0037] Ingredients → casting → sawing → heating → hot rollin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com