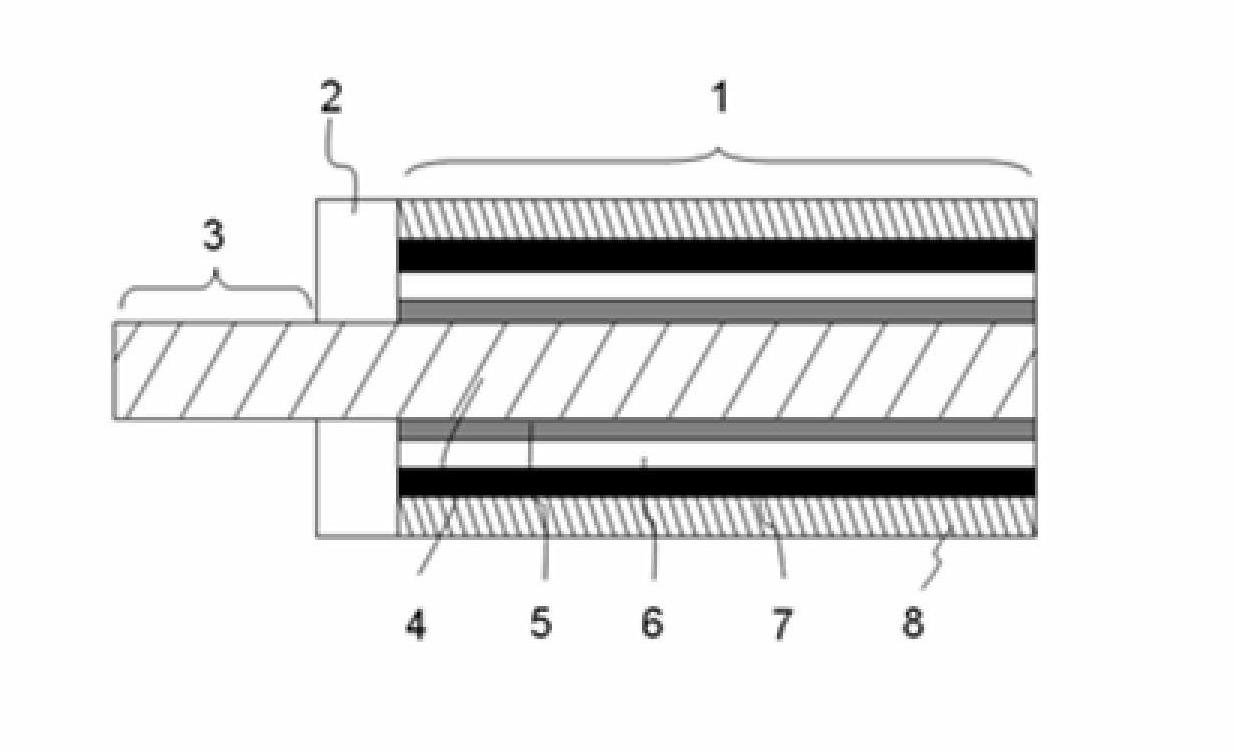

Solid electrolytic capacitor carbon rubber layer and manufacture method thereof

A solid electrolysis and capacitor technology, applied in the direction of solid electrolytic capacitors, electrolytic capacitors, capacitors, etc., can solve the problems of poor conductivity of the carbon glue layer and the thickness of the carbon glue layer, so as to reduce the carbon content and increase the bonding force. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

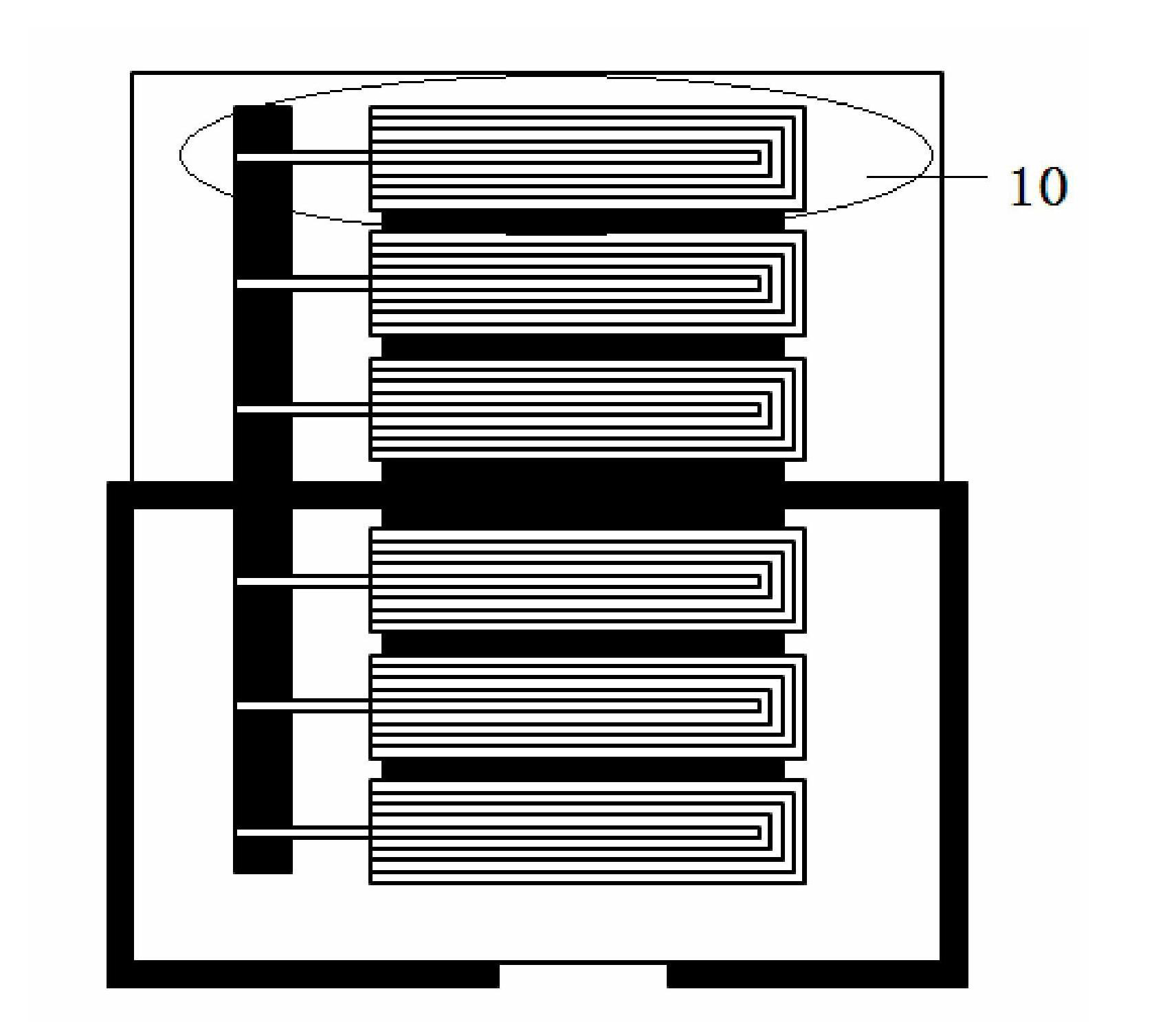

[0055] A method for preparing a solid electrolytic capacitor carbon glue layer, comprising the following preparation steps:

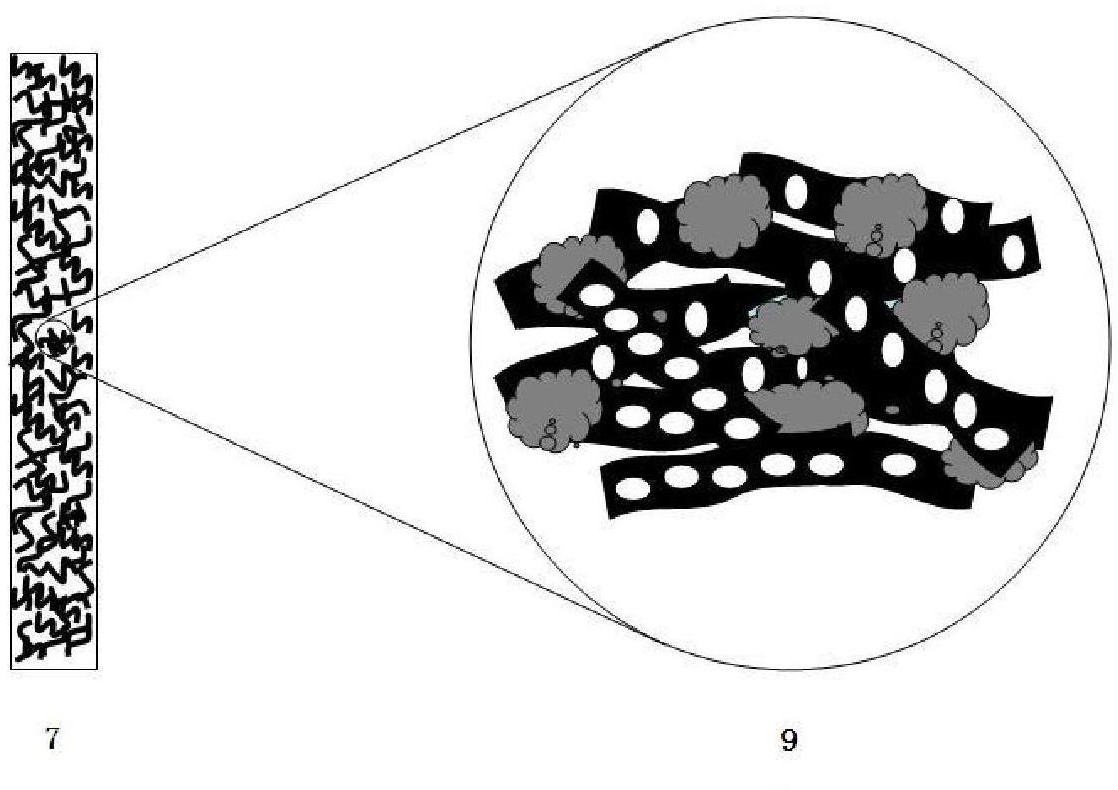

[0056] (1) Weigh a certain amount of graphene derived material powder produced by the method described in patent CN102070140A, place it in an agate mortar, and grind it evenly; the ground powder, organic solvent N,N-dimethylformamide (DMF) ) and the binder epoxy resin in parts by mass: graphene 5%; binder 30%; organic solvent 65% after mixing and stirring, ultrasonication for 30 minutes to obtain a uniformly dispersed black suspension;

[0057] (2) The electrode that needs to be coated with the carbon glue layer is covered with the graphene carbon glue layer by the dipping method in the graphene suspension;

[0058] (3) Pre-bake in an oven at 80°C for 10 minutes, and bake in an oven at 150°C for 30-60 minutes to cure.

[0059] (4) Test the resistivity of the carbon adhesive layer: coat a 10mm×40mm×25μm carbon adhesive layer film on the glass slide, pre...

Embodiment 2

[0062] A method for preparing a solid electrolytic capacitor carbon glue layer, comprising the following preparation steps:

[0063] (1) Weigh a certain amount of graphene-derived material powder produced by the method described in patent CN102070140A, place it in an agate mortar, and grind it evenly; the ground powder, organic solvent 1-methyl-2-pyrrolidone and bonding Agent polymethyl methacrylate in parts by mass: graphene 10%; binder 30%; organic solvent 60% after mixing and stirring, ultrasonication for 30 minutes to obtain a uniformly dispersed black suspension;

[0064] (2) The electrode that needs to be coated with the carbon glue layer is covered with the graphene carbon glue layer by the dipping method in the graphene suspension;

[0065] (3) Pre-bake in an oven at 80°C for 10 minutes, and bake in an oven at 150°C for 30-60 minutes to cure.

[0066] (4) Test the resistivity of the carbon adhesive layer: coat a 10mm×40mm×25μm carbon adhesive layer film on the glass s...

Embodiment 3

[0069] A method for preparing a solid electrolytic capacitor carbon glue layer, comprising the following preparation steps:

[0070] (1) Weigh a certain amount of graphene material powder, place it in an agate mortar, and grind it evenly; mix the ground powder, organic solvent dimethyl sulfoxide and binder acrylic resin according to the mass fraction: graphene 0.1% ; Binder 35%; Organic solvent 64.9% after mixing and stirring, ultrasonic for 30 minutes to obtain a uniformly dispersed black suspension;

[0071] (2) The electrode that needs to be coated with the carbon glue layer is covered with the graphene carbon glue layer by the dipping method in the graphene suspension;

[0072] (3) Pre-bake in a 60°C oven for 15 minutes, and bake in a 200°C oven for 100 minutes to cure.

[0073] (4) Test the resistivity of the carbon adhesive layer: coat a 10mm×40mm×25μm carbon adhesive layer film on the glass slide, pre-bake it in an oven at 80°C for 10min, then cure it in an oven at 150...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com