High-strength, high-conductivity and high-temperature-resistant Cu-Cr-Nb-Zr alloy and preparation method thereof

A cu-cr-nb-zr, high temperature resistant technology, applied in metal processing equipment, manufacturing tools, welding equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

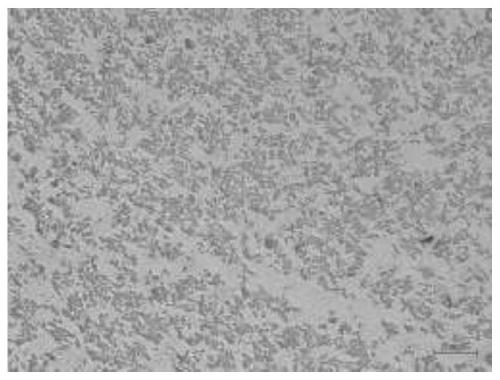

Image

Examples

Embodiment 1

[0036] A high-strength, high-conductivity and high-temperature-resistant Cu-Cr-Nb-Zr alloy, the weight percentage of the alloy is composed of: Cr: 6.65wt%, Nb: 5.84wt%, Zr: 0.32wt%, Fe: 0.004wt%, O: 0.015wt%, Cu: 87.171%, by controlling the composition ratio between Cr and Nb, using the synergistic effect of the metal compound formed between Cr and Nb under this ratio, the conductivity of the material can be improved without reducing the conductivity of the material. Strength, while Cr 2The Nb hardening phase can refine and control the grain size of copper, and further improve the strength of the copper alloy. Cu is made of electrolytic copper plate with a purity of 99.990%, Cr is added by CuCr10 master alloy, Zr is added by CuZr master alloy, and Nb is made of CrNb38 master alloy way to join.

[0037] The preparation method of the above-mentioned high-strength, high-conductivity and high-temperature resistant Cu-Cr-Nb-Zr alloy specifically includes the following steps:

[0...

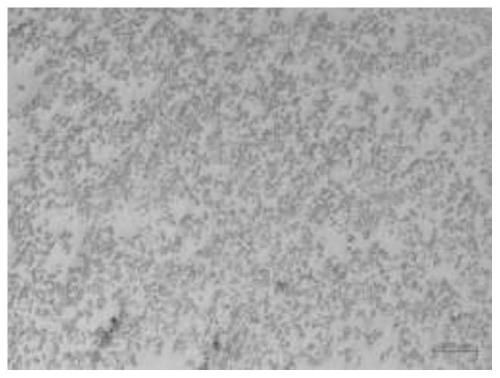

Embodiment 2

[0047] A high-strength, high-conductivity, high-temperature resistant Cu-Cr-Nb-Zr alloy, the weight percentage of the alloy is composed of: Cr: 6.52wt%, Nb: 5.53wt%, Zr: 0.25wt%, Fe: 0.003wt%, O: 0.01wt%, Cu: 87.687%, by controlling the composition ratio between Cr and Nb, using the synergistic effect of the metal compound formed between Cr and Nb under this ratio, the conductivity of the material can be improved without reducing the conductivity of the material. Strength, while Cr 2 The Nb hardening phase can refine and control the grain size of copper, and further improve the strength of the copper alloy. Cu is made of electrolytic copper plate with a purity of 99.998%, Cr is added by CuCr10 master alloy, Zr is added by CuZr master alloy, and Nb is made of CrNb38 master alloy way to join.

[0048] The preparation method of the above-mentioned high-strength, high-conductivity and high-temperature resistant Cu-Cr-Nb-Zr alloy specifically includes the following steps:

[0049...

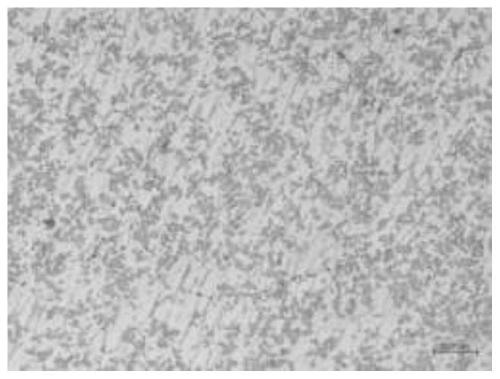

Embodiment 3

[0058] A high-strength, high-conductivity and high-temperature-resistant Cu-Cr-Nb-Zr alloy, the weight percentage of the alloy is composed of: Cr: 6.67wt%, Nb: 5.86wt%, Zr: 0.31wt%, Fe: 0.002wt%, O: 0.005wt%, Cu: 87.153%, by controlling the composition ratio between Cr and Nb, using the synergistic effect of the metal compound formed between Cr and Nb under this ratio, the material conductivity can be improved without reducing the material conductivity. Strength, while Cr 2 The Nb hardening phase can refine and control the grain size of copper, and further improve the strength of the copper alloy. Cu is made of electrolytic copper plate with a purity of 99.999%, Cr is added by CuCr10 master alloy, Zr is added by CuZr master alloy, and Nb is made of CrNb38 master alloy way to join.

[0059] The preparation method of the above-mentioned high-strength, high-conductivity and high-temperature resistant Cu-Cr-Nb-Zr alloy specifically includes the following steps:

[0060] (1) Ingr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com