Manufacturing process of flexible amorphous silicon solar cell

A technology for solar cells and manufacturing processes, applied in sustainable manufacturing/processing, final product manufacturing, circuits, etc., can solve problems such as undiscovered, and achieve the effect of low cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

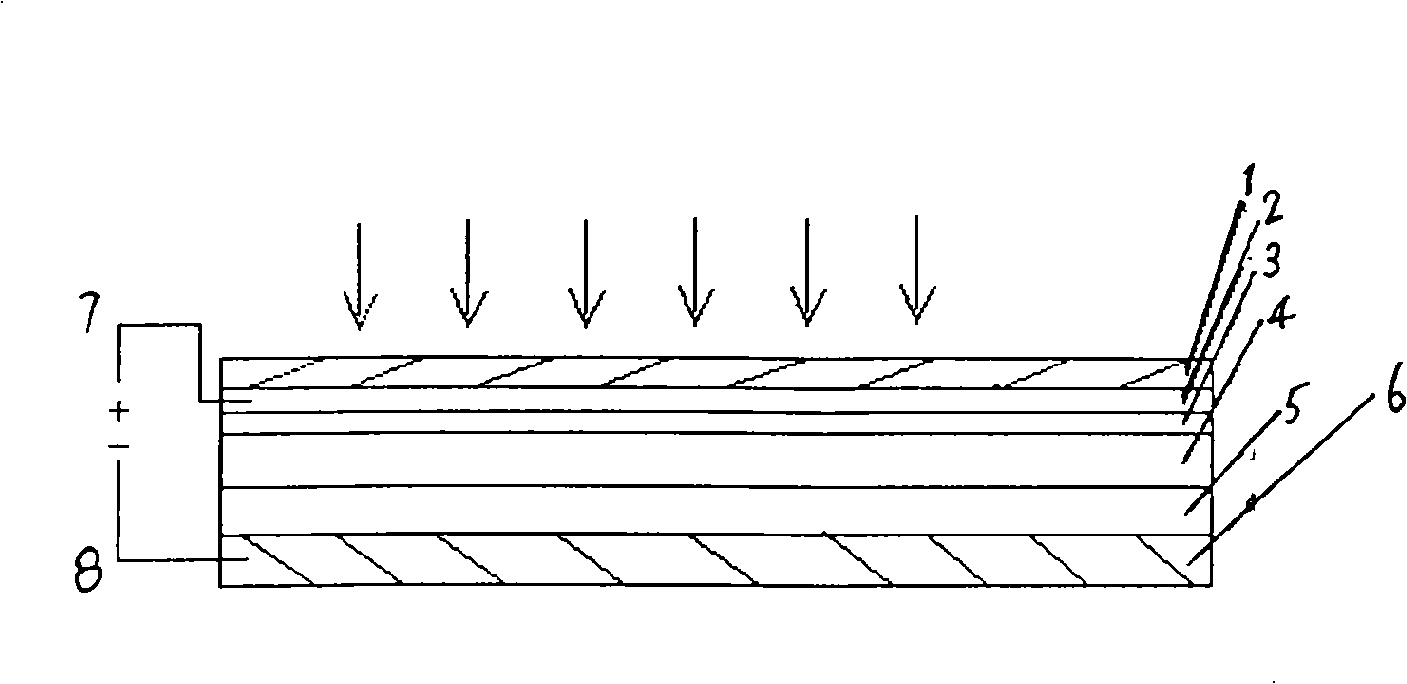

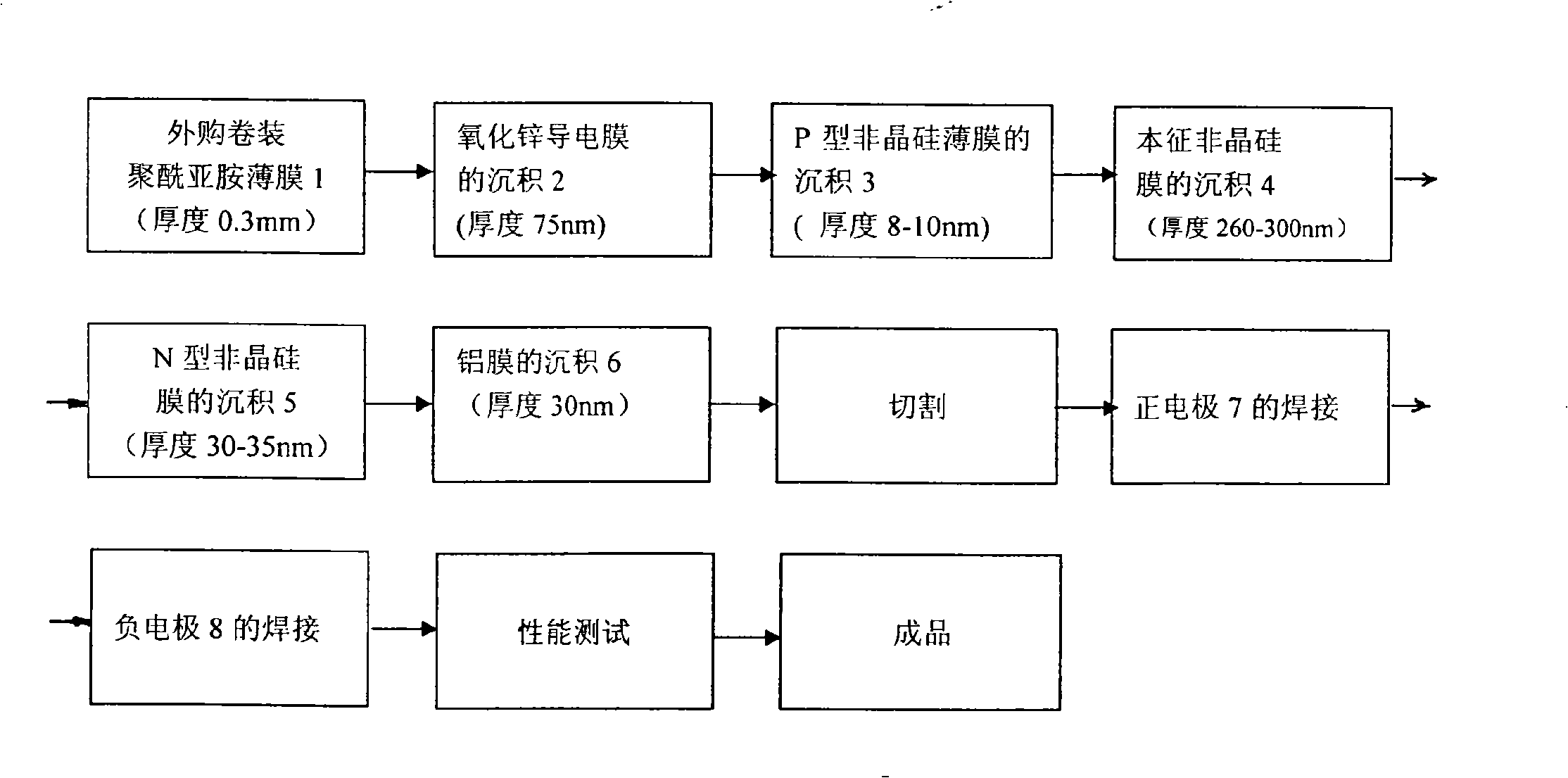

[0016] Please refer to the attached figure 1 Shown, the present invention is irradiated by sunlight, and each coating layer inward is: high light transmittance polyimide film 1, zinc oxide conductive film 2, P-type amorphous silicon film 3, intrinsic type amorphous silicon film 4, N-type amorphous silicon film 5, aluminum film 6; Manufacturing process of the present invention is as follows:

[0017] The patent of the present invention adopts externally purchased roll-shaped transparent polyimide film as the base of the battery. The thickness of the film is 0.3mm, the light transmittance is higher than 92%, and it can withstand high temperatures above 300°C. The width of the film is 30cm, and the length is 1000m. It is wound on a metal roller with bearings. The first step is to put the roller into the deposition chamber of a conventional magnetron sputtering equipment, mount it on a bearing frame, so that it can rotate smoothly, and wrap it on the roller The polyimide film at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com