Special-shaped solar photovoltaic curtain wall glass and manufacturing method thereof

A solar photovoltaic, solar cell technology, applied in photovoltaic power generation, final product manufacturing, sustainable manufacturing/processing, etc., can solve problems such as non-involvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

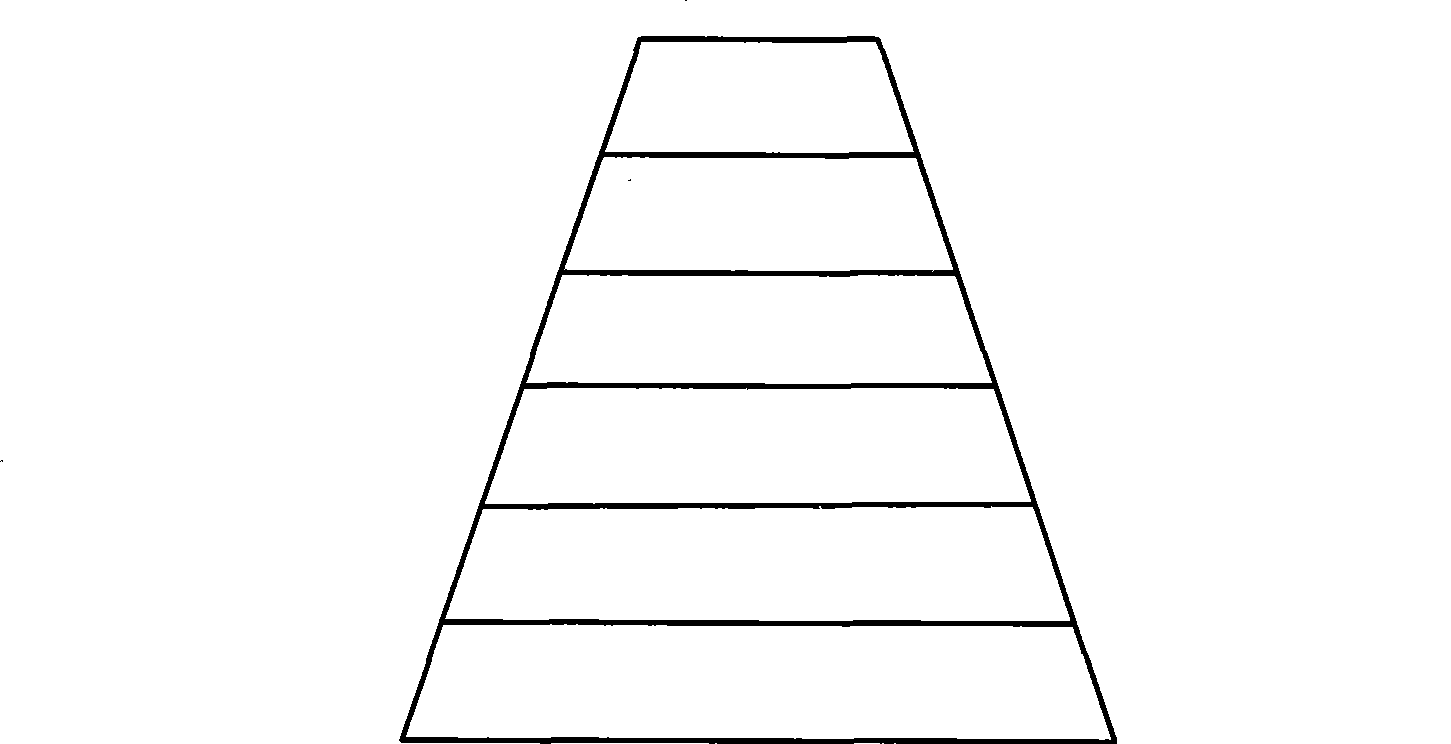

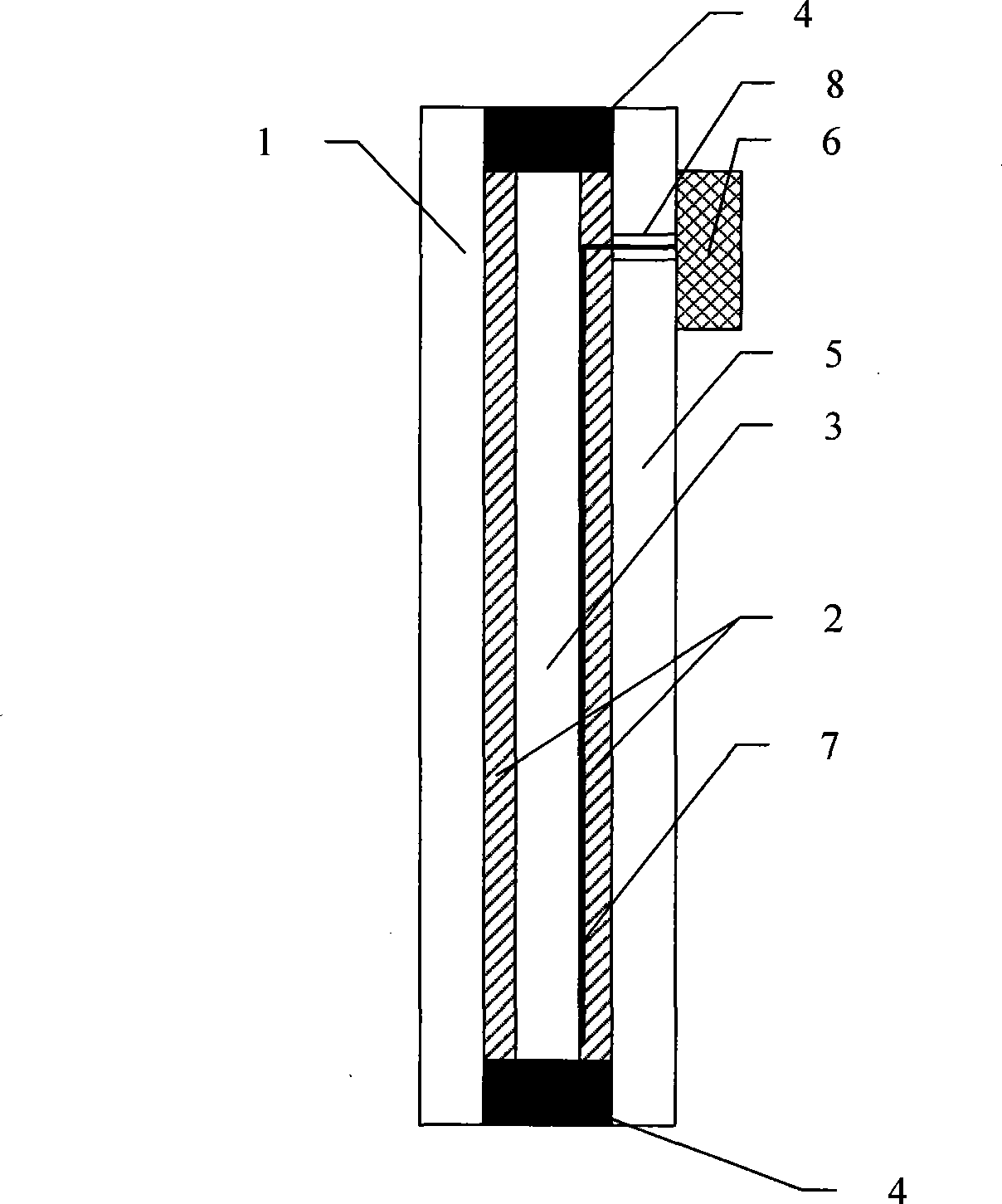

[0042] See image 3 , the special-shaped solar photovoltaic curtain wall glass is trapezoidal, and the trapezoidal solar cell core board is used as the photoelectric interlayer of the photovoltaic curtain wall glass. The cell core board includes multiple solar cell modules connected in parallel. The production steps are as follows:

[0043] Step 1: Process the window layer glass (or outer layer glass 1): Process the window layer glass according to the shape of the curtain wall glass, and the light transmittance of the glass must meet the performance requirements of the photovoltaic module.

[0044] Step 2: Clean the window layer glass: Clean the window layer glass with alcohol or acetone.

[0045] Step 3: Cover the glass with a PVB sealing film 2, which is also called an adhesive material.

[0046] Step 4: Make the photoelectric interlayer of special-shaped photovoltaic curtain wall glass from the solar cell core board, the steps are as follows:

[0047] Laser scribes the fr...

Embodiment 2

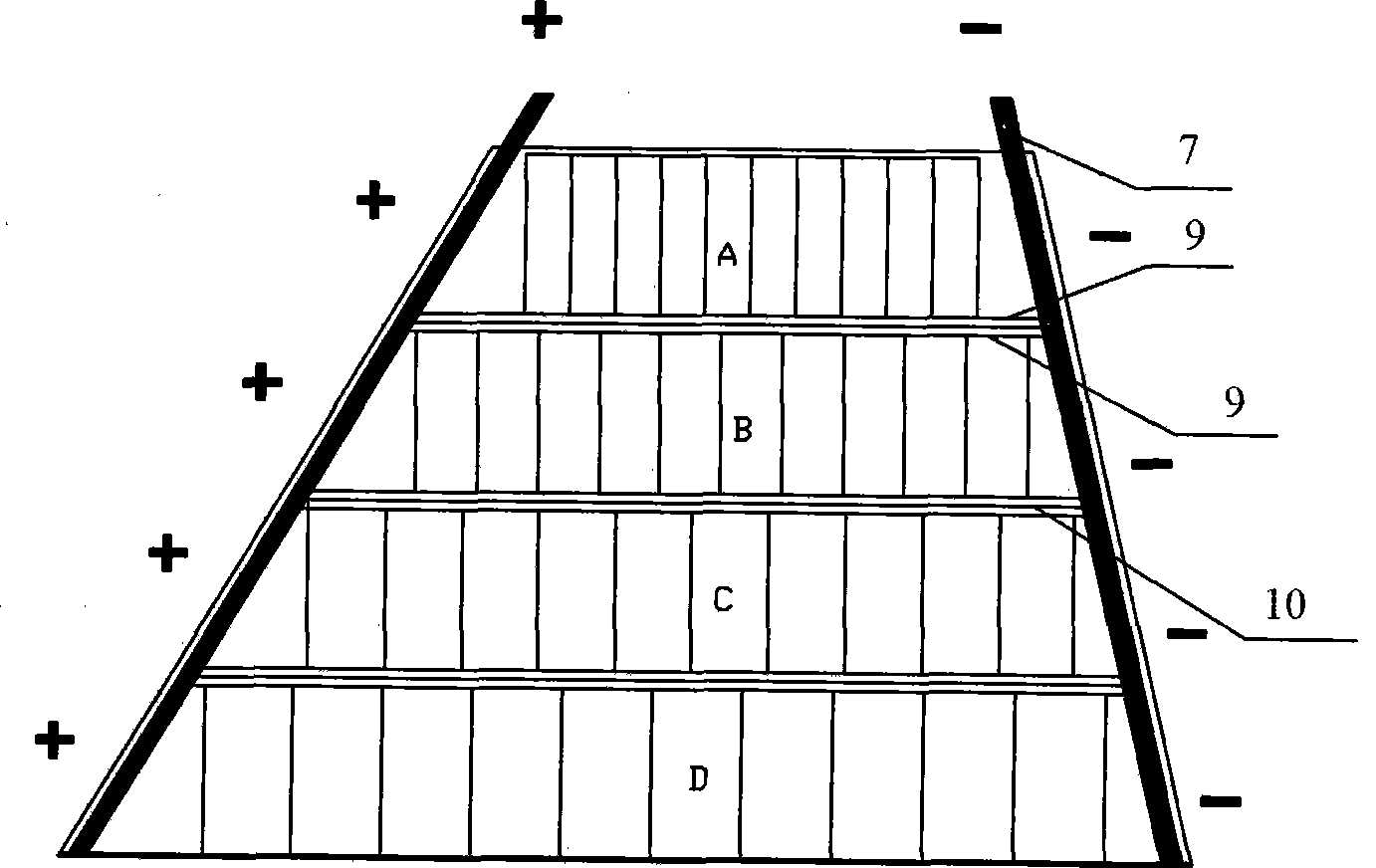

[0067] See Figure 4 , the special-shaped solar photovoltaic curtain wall glass is trapezoidal, and the trapezoidal solar cell core board is used as the photoelectric interlayer of the photovoltaic curtain wall glass. The cell core board includes multiple solar cell modules connected in series. The manufacturing steps are as follows:

[0068] The method of the first step to the third step is with embodiment 1.

[0069] Step 4: Make the photoelectric interlayer of special-shaped photovoltaic curtain wall glass from the solar cell core board, and the process is as follows:

[0070] The laser scribes the front electrode layer of the battery core board, and scribes the front electrode layer into four areas, A, B, C, and D, or four solar cell modules. The laser frequency used is 5.0-8.0KHz;

[0071] Scribing the sub-cells with a laser in the area so that the effective area of each sub-cell is the same, so that the current of the sub-cells of the battery assembly is the same;

...

Embodiment 3

[0081] Make the trapezoidal solar photovoltaic curtain wall glass with a curved waist, and use the trapezoidal solar cell core board with a curved waist as the photoelectric interlayer of the photovoltaic curtain wall glass.

[0082] Use a laser to scribe the amorphous silicon solar cell core board, divide it into multiple regions (also known as amorphous silicon solar cell components), each region has the same number of sub-cells, and multiple amorphous silicon solar cell components Connect in parallel to make the voltage of each area consistent, forming a trapezoidal amorphous silicon solar cell core board with a radian at the waist, which is used as a photoelectric interlayer of solar photovoltaic curtain wall glass. The manufacturing method of the trapezoidal photovoltaic curtain wall glass with radian at the waist is the same as that in Example 1. The positive and negative electrodes of each amorphous silicon solar cell core board are drawn in parallel from the corners by ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Edge width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com