Spliced bamboo floor

A technology of bamboo flooring and splicing parts, which is applied in the direction of floors, buildings, building structures, etc., can solve the problems of long floor laying and cannot be reused, and achieve the effects of fast splicing speed, low cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

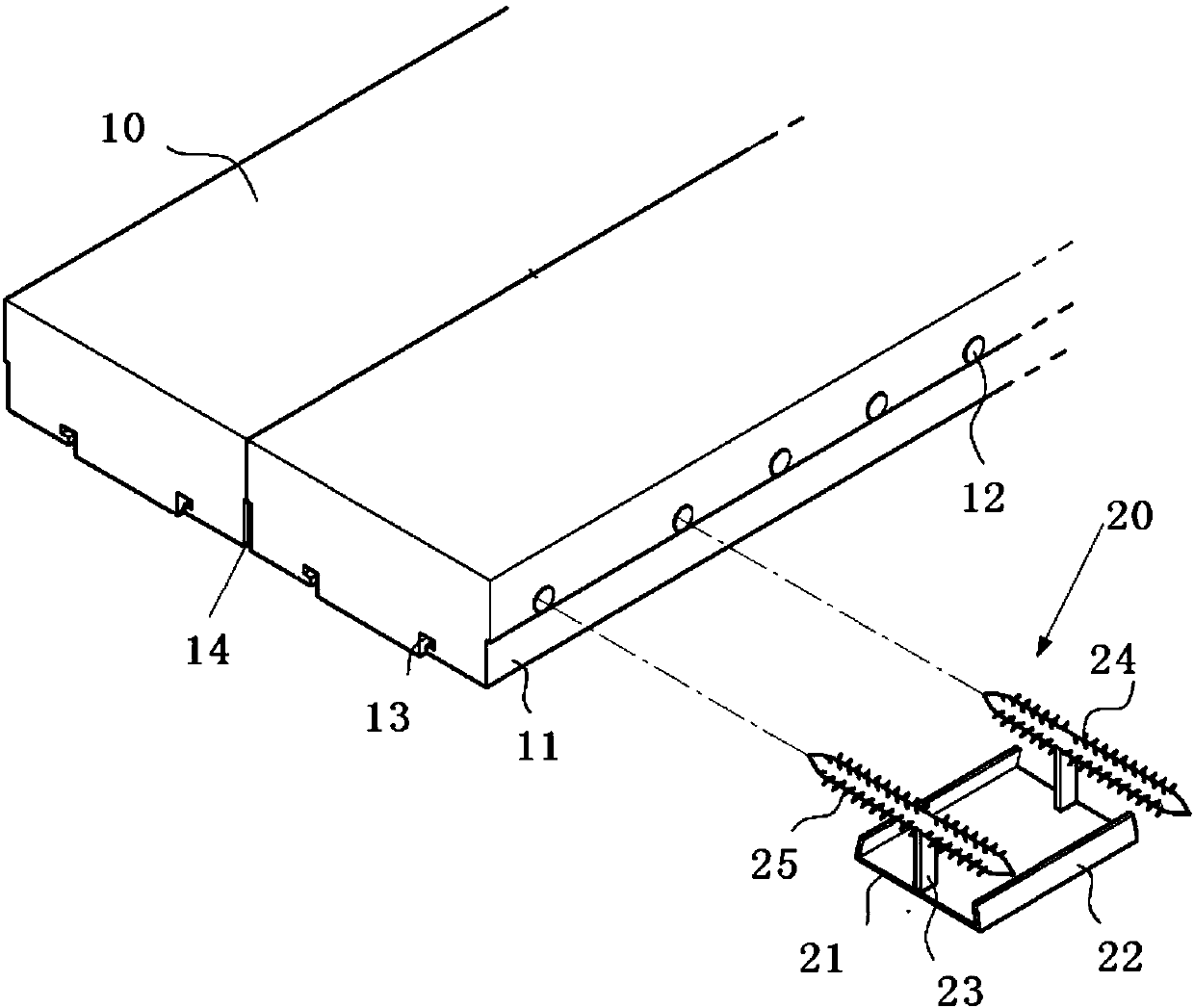

[0014] Such as figure 1 As shown, a kind of splicing bamboo flooring comprises bamboo veneer 10 and splicing piece 20, and bamboo veneer 10 is spliced into the whole floor by splicing piece 20, and bamboo veneer 10 adopts elongated board, and bamboo veneer The side surfaces on both sides of the length direction of the 10 are divided into upper and lower halves, and a plurality of connecting holes 12 are uniformly distributed along the length direction of the sides on the upper half, and the lower half of the side of the bamboo veneer 10 is provided with gaps 11, A splicing seam 14 is formed between the gaps 11 of the two connected bamboo veneers 10, a splicing piece 20 is arranged at the splicing seam 14, and a splicing groove is arranged on the bottom surface of the bamboo veneer 10 on both sides of the splicing seam 14. 13. The splicing groove 13 extends along the length direction of the bamboo veneer 10.

[0015] The structure of the splicing piece 20 is as shown in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com