A large-area defect-free two-dimensional colloidal single crystal, its preparation method and its transfer method

A two-dimensional colloid, large-area technology, applied in the direction of single crystal growth, single crystal growth, chemical instruments and methods, etc., can solve the problems of the hydrophilicity and hydrophobicity of the substrate surface, time-consuming and other problems, and achieve a simple and efficient preparation method and a wide range of applications. Wide range of effects with simple ingredients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

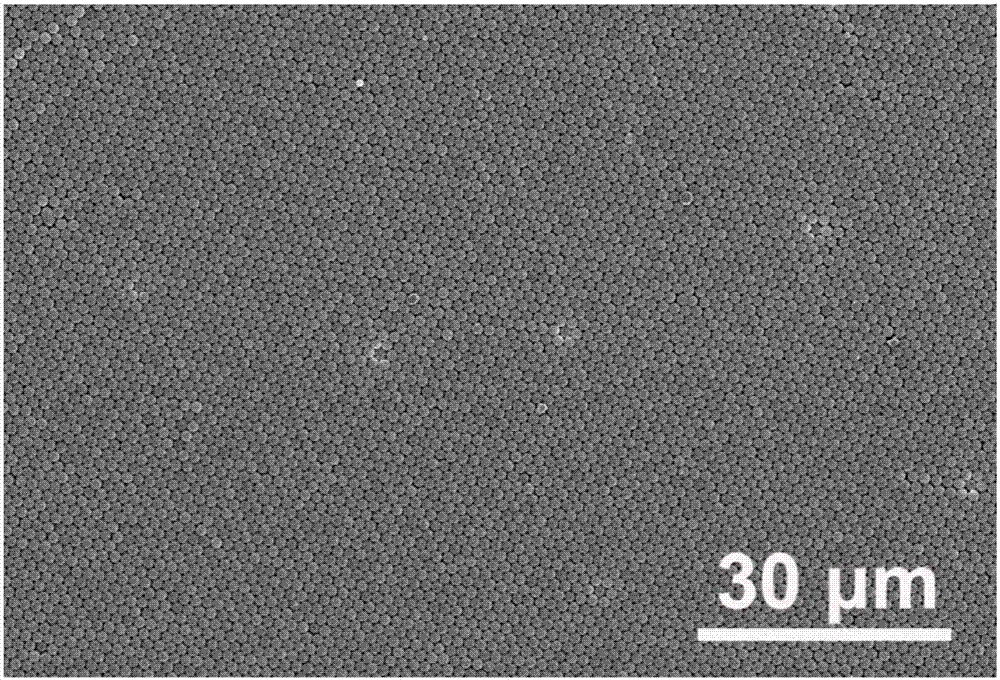

Embodiment 1

[0043] The raw materials are monodisperse spherical polystyrene particles with a diameter of 1.4 μm, sodium dodecylsulfonate, ethanol, butanol, and pure water. Among them, based on the amount of pure water, the concentration of sodium dodecylsulfonate is 17.9 mg / mL; the ratio of ethanol and butanol in the colloidal particle suspension system is 1:7 (v:v), and the amount of glycol is As a standard, the concentration of colloidal particles was 30.0 mg / mL. First disperse the colloidal particles in the glycol dispersion medium, after the ultrasonic dispersion is uniform, drop by drop to the surface of pure water dissolved in sodium dodecylsulfonate. While dripping the suspension of colloidal particles dispersed, apply airflow (flow rate: 6.0L / min) to the water surface through a flat nozzle. After the colloidal particles cover the entire water surface, the colloidal particles no longer move with the airflow. Increase the air flow rate (10.0L / min), move the nozzle left and right at...

Embodiment 2

[0046] The raw materials are monodisperse spherical polystyrene particles with a diameter of 1.4 μm, sodium dodecylsulfonate, ethanol, butanol, and pure water. Among them, based on the amount of pure water, the concentration of sodium dodecylsulfonate is 35.7 mg / mL; the ratio of ethanol and butanol in the colloidal particle suspension system is 1:7 (v:v), and the amount of glycol is As a standard, the concentration of colloidal particles was 30.0 mg / mL. First disperse the colloidal particles in the glycol dispersion medium, after the ultrasonic dispersion is uniform, drop by drop to the surface of pure water dissolved in sodium dodecylsulfonate. While dripping the suspension of colloidal particles dispersed, apply airflow (flow rate: 6.0L / min) to the water surface through a flat nozzle. After the colloidal particles cover the entire water surface, the colloidal particles no longer move with the airflow. Increase the air flow rate (10.0L / min), move the nozzle left and right at...

Embodiment 3

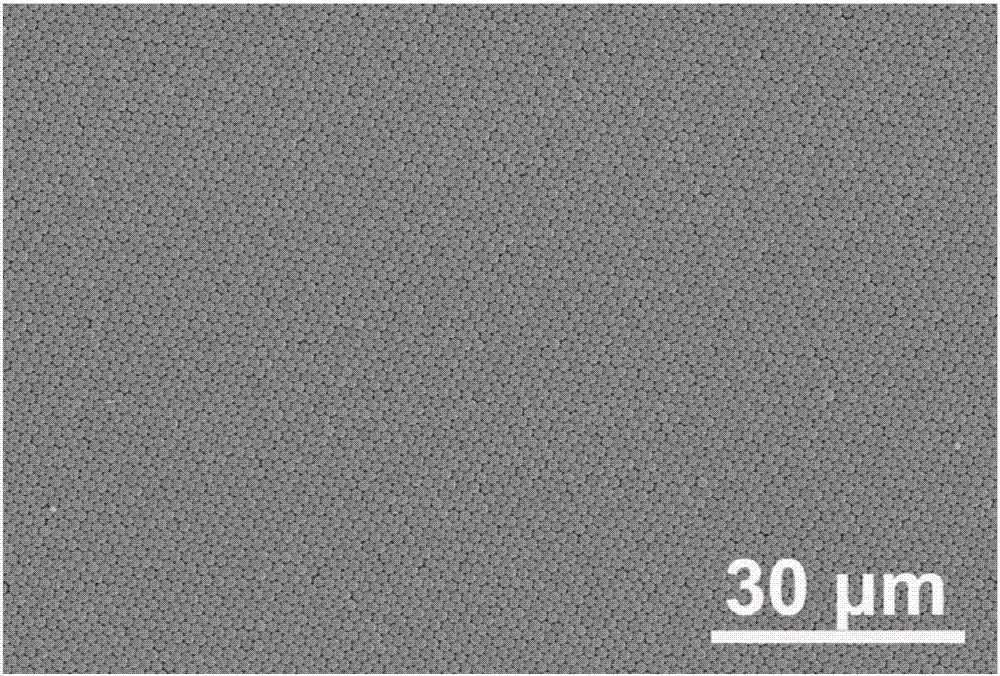

[0049] The raw materials are monodisperse spherical polystyrene particles with a diameter of 0.8 μm, sodium dodecylsulfonate, ethanol, butanol, and pure water. Among them, based on the amount of pure water, the concentration of sodium dodecylsulfonate is 35.7 mg / mL; the ratio of ethanol and butanol in the colloidal particle suspension system is 1:7 (v:v), and the amount of glycol is As a standard, the concentration of colloidal particles was 30.0 mg / mL. First disperse the colloidal particles in the glycol dispersion medium, after the ultrasonic dispersion is uniform, drop by drop to the surface of pure water dissolved in sodium dodecylsulfonate. While dripping the suspension of colloidal particles dispersed, apply airflow (flow rate: 6.0L / min) to the water surface through a flat nozzle. After the colloidal particles cover the entire water surface, the colloidal particles no longer move with the airflow. Increase the air flow rate (10.0L / min), move the nozzle left and right at...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com