Weak-brightness non-crystal silicon solar cell manufacture method using laser etching transparent electrode

A solar cell and transparent electrode technology, applied in the field of solar cells, can solve the problems of increasing waste comprehensive treatment expenditure, affecting product electrical performance, and consuming more raw materials, so as to improve product yield, simplify production process, and reduce raw material loss. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The present invention is a method for manufacturing a low-light amorphous silicon solar cell that uses a laser to mark a transparent electrode. Embodiment 1 is a method for producing an inline low-light amorphous silicon solar cell whose product model is N8527.

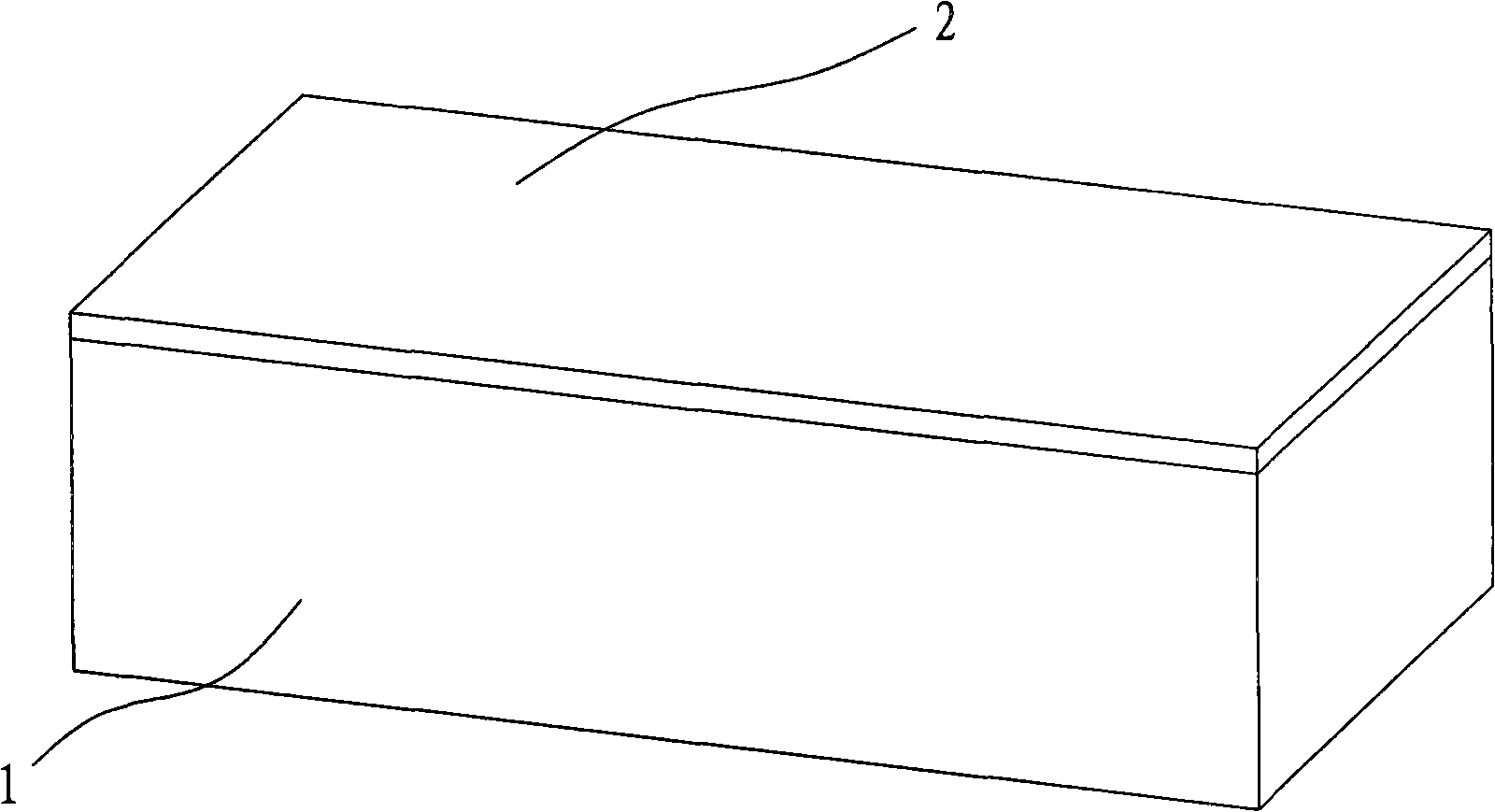

[0025] like figure 1 As shown, the conductive glass used in this embodiment includes a glass substrate 1 and an indium tin oxide transparent conductive film 2. The glass substrate 1 is an ultra-thin ITO conductive glass with a thickness of 1.1mm, and its external dimensions are 406.4mm long and 355.6mm wide. mm, thickness 1.1mm. The surface of the glass substrate 1 is sputter-deposited with a thickness of 600A 0 indium tin oxide transparent conductive film 2 .

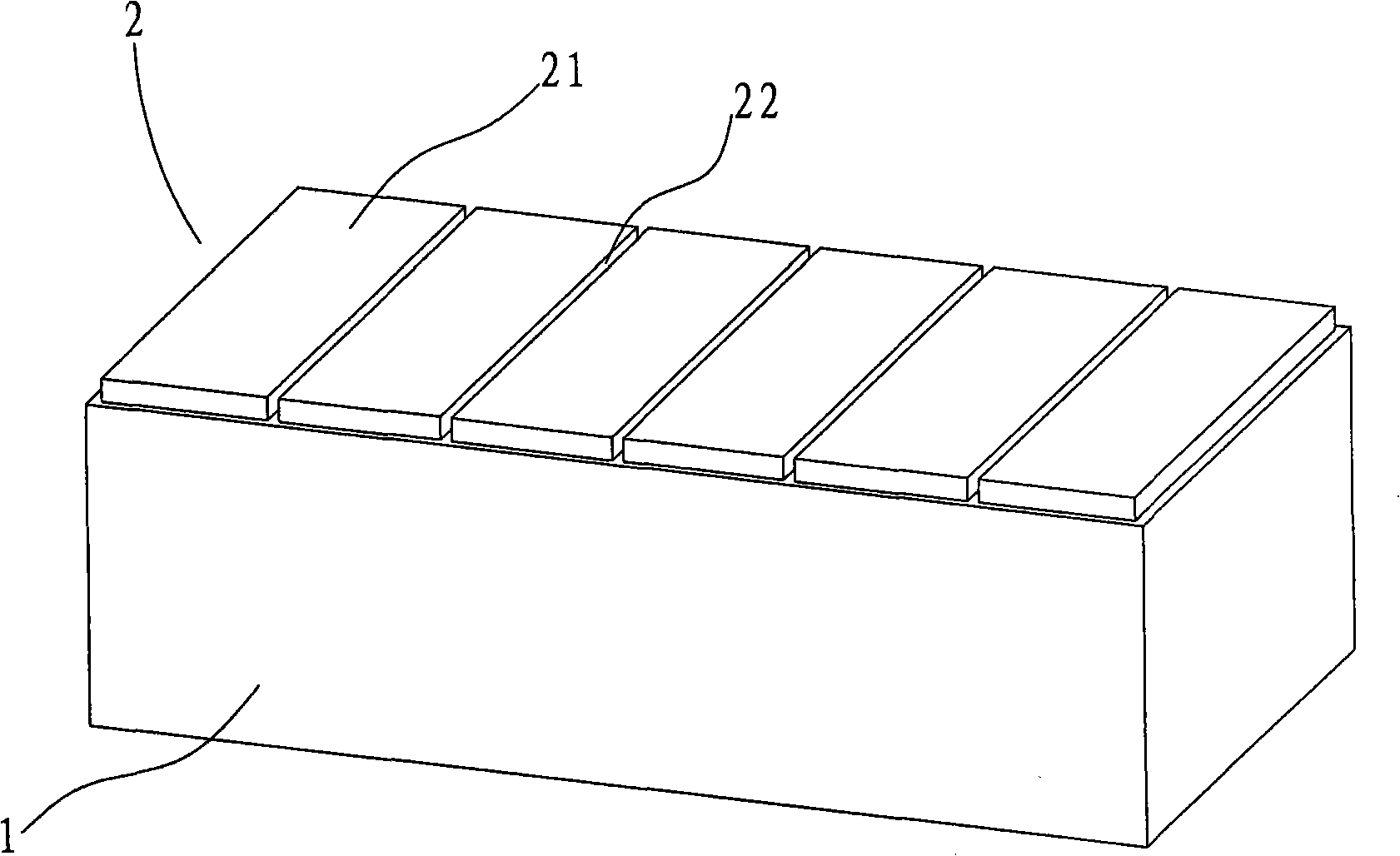

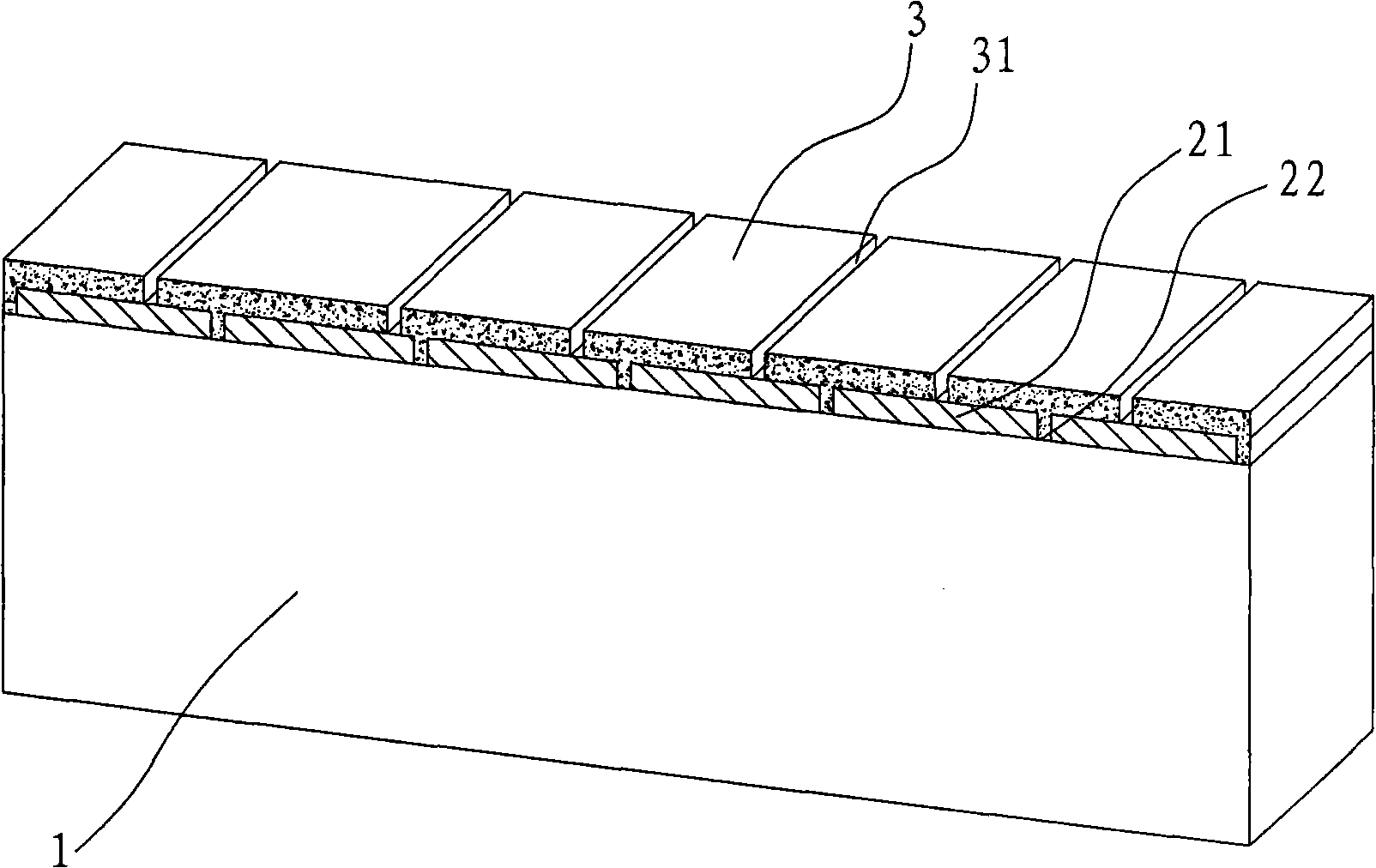

[0026] First of all, clean the conductive glass through a cleaning machine, and set it on the program of the red laser marking machine, such as figure 2 As shown, the transparent conductive film 2 of the ultra-thin ITO conductive glass is marked wit...

Embodiment 2

[0037] Embodiment 2 of the present invention is a method for producing Wailian low-light amorphous silicon solar cells whose product model is W5514.

[0038] The conductive glass in the present embodiment is still the conductive glass used in embodiment one, as figure 1 As shown, it includes a glass substrate 1 and an indium tin oxide transparent conductive film 2. The glass substrate 1 is an ultra-thin ITO conductive glass with a thickness of 1.1mm, and its dimensions are 406.4mm in length, 355.6mm in width and 1.1mm in thickness. The surface of the glass substrate 1 is sputter-deposited with a thickness of 600A 0 indium tin oxide transparent conductive film 2 .

[0039] Firstly, the conductive glass is cleaned by a cleaning machine, and then, the program of the red laser marking machine is set, and the transparent conductive film 2 is marked by the red laser marking machine as shown in the following figure: Figure 5 In the five amorphous silicon solar cell transparent ele...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com