Method and ink for etching amorphous silicon solar battery aluminum membrana

A technology for solar cells and amorphous silicon thin films, applied in circuits, electrical components, climate sustainability, etc., can solve the problems of unsuitability for large-scale production, low production efficiency, and many etching processes, and achieve the benefits of large-scale continuous The effect of optimizing production, improving production efficiency and reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

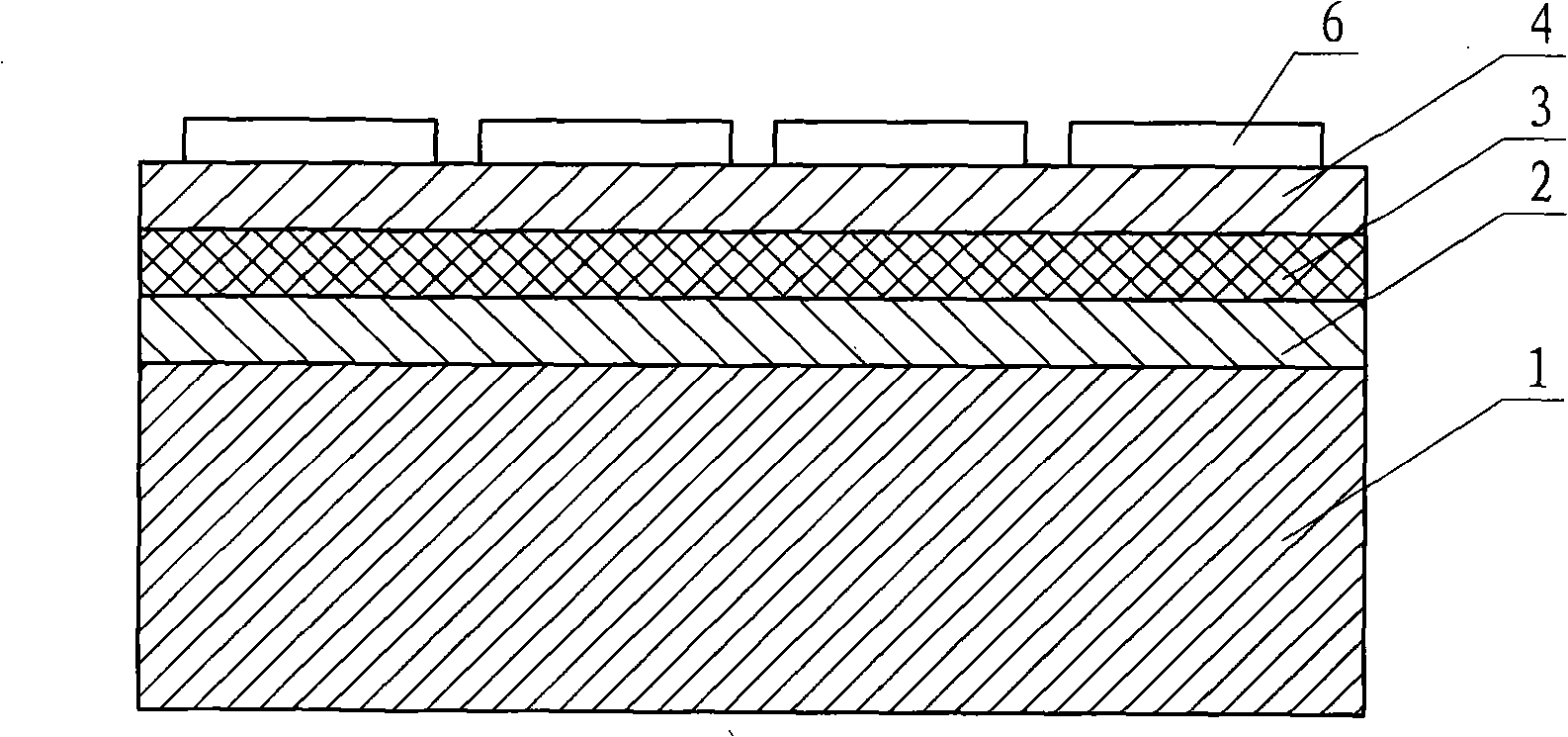

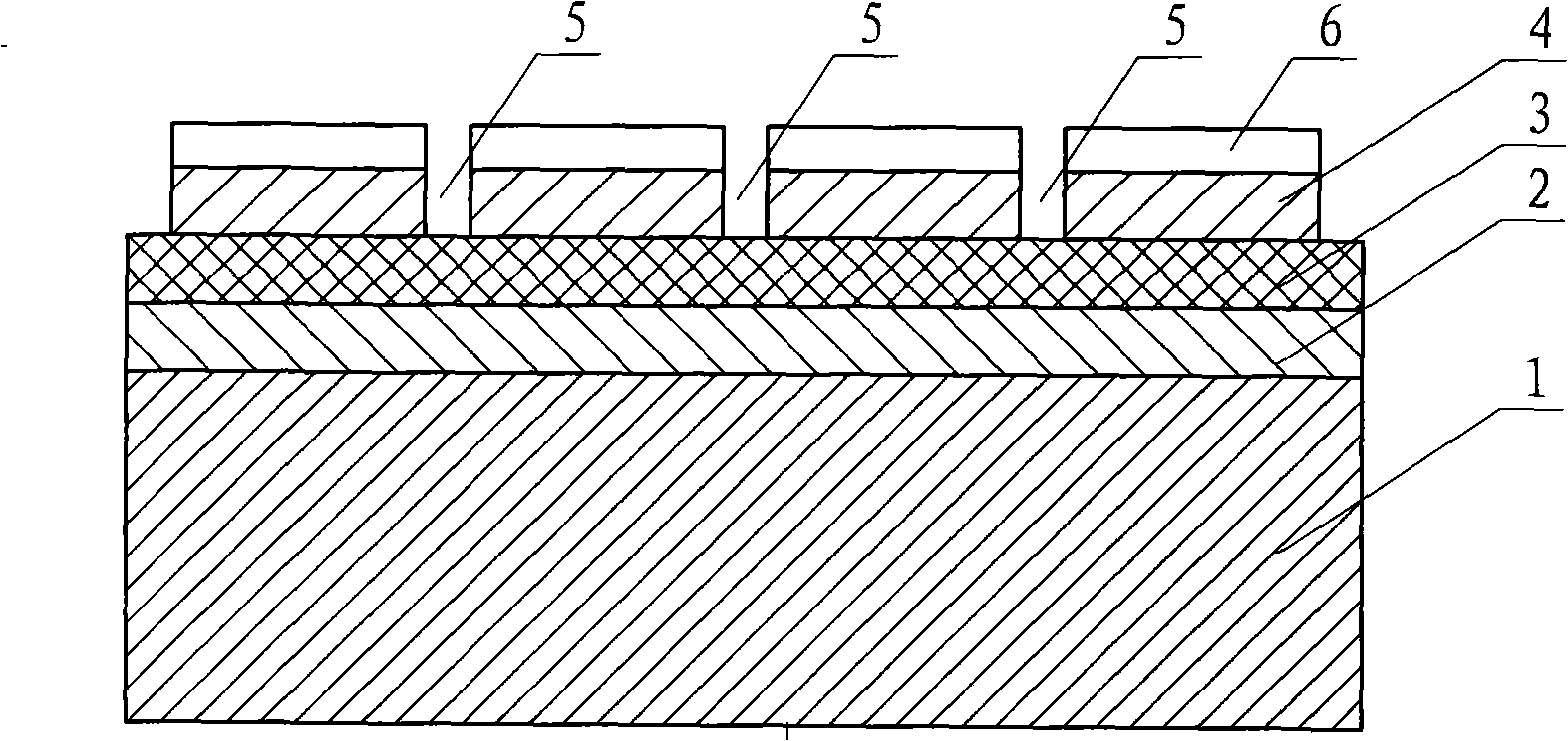

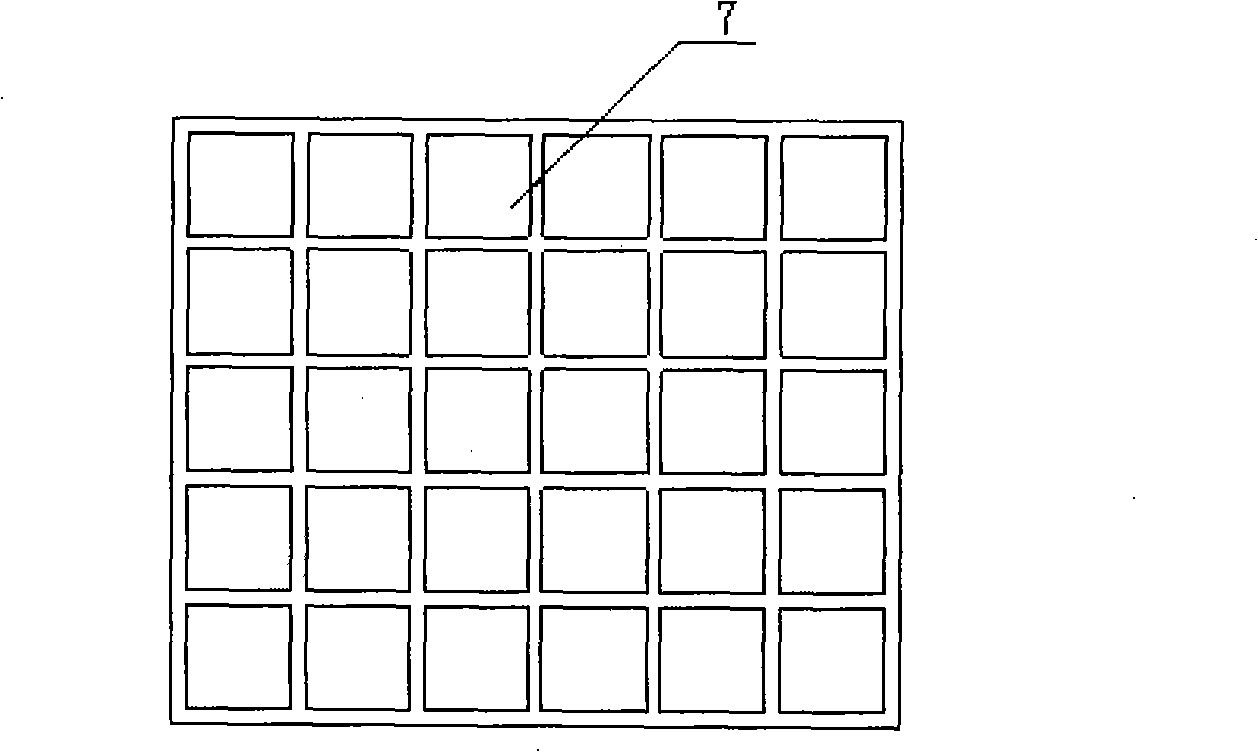

[0025] image 3 It is the schematic diagram of this embodiment, and the specification is 70mm×70mm solar cells. in SnO 2 On the conductive glass, use a laser to scribe the transparent conductive film to form an electrode pattern, and use an automatic continuous cleaning machine to clean the transparent conductive glass with the electrode pattern formed. Put the cleaned transparent conductive glass into a special fixture, send it into an oven, and preheat it at a temperature of 250°C, and place it on the SnO 2 An amorphous silicon thin film layer is deposited on the conductive film. Use laser to scribe amorphous silicon to form amorphous silicon thin film battery pattern. On the amorphous silicon thin film layer, an aluminum back electrode layer is prepared by vacuum evaporation, and an aluminum back electrode pattern is formed through a mask frame. After aluminum plating, the UV-ink made of polymer materials is used to screen-print the back paint protection layer. After be...

Embodiment 2

[0027] The manufacturing process of the cell sheet with a size of 50mm×50mm is the same as Example 1, the difference is the preparation of alkaline etching ink. Take 1790 grams of water, add 190 grams of KOH, stir to dissolve, add 155 grams of WT-115 thickener, stir to thicken, add 11 grams of water-based defoamer W-090 and 36 grams of water-based leveling agent Leaslip455, and stir Evenly, alkaline etching ink is prepared.

Embodiment 3

[0029] The manufacturing process of the cell sheet with a size of 70mm×70mm is the same as Example 1, the difference is the preparation of alkaline etching ink. Take 1790 grams of water, add 100 grams of NaOH, stir to dissolve, add 150 grams of WT-115 thickener, stir to thicken, add 11 grams of water-based defoamer W-090 and 36 grams of water-based leveling agent Leaslip455, and stir Evenly, alkaline etching ink is prepared.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com