Patents

Literature

44results about How to "Conducive to large-scale continuous production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method of continuously preparing 1,2-dihydroxypropane by glycerin catalytic hydrogenation

The invention discloses a making method of 1, 2-propanediol under mild condition, which is characterized by the following: adopting copper, zinc and manganese and or aluminium catalyst; aerating glycerin and hydrogen continuously from the top of reactor; hydrogenating glycerin at 200-250 deg.c under 2.5-5Mpa; outputting and collecting reacting product from the bottom of reactor continuously; separating gas; returning to recycle; setting the weight rate of metal element of catalyst at 16-48:24-48:0.15-4:0-8.

Owner:NANJING TECH UNIV

Method for making stewed duck with bean sauce

InactiveCN101715974ASolve processabilitySolve for uniformityFood preparationBiotechnologyAdditive ingredient

The invention relates to the field of food processing and discloses a method for making a stewed duck with bean sauce. In the invention, injection seasoning technology, vacuum massaging technology and compression marinating technology are integrated into a novel processing technique. The stewed duck with bean sauce made by the invention has the advantages of rich sauce fragrance, tender meat quality, proper elasticity and unique taste. The method overcomes the defects that the traditional stewed ducks with bean sauce cannot be pickled uniformly and the making period is too long, can effectively keep nutrient components in the duck, and can prolong the shelf life of the finished product. The raw materials and making parameters of the method are quantified, so the method can ensure the stable quality of products, facilitates the quality control, and has a prospect for large-scale industrialized production.

Owner:夏威夷

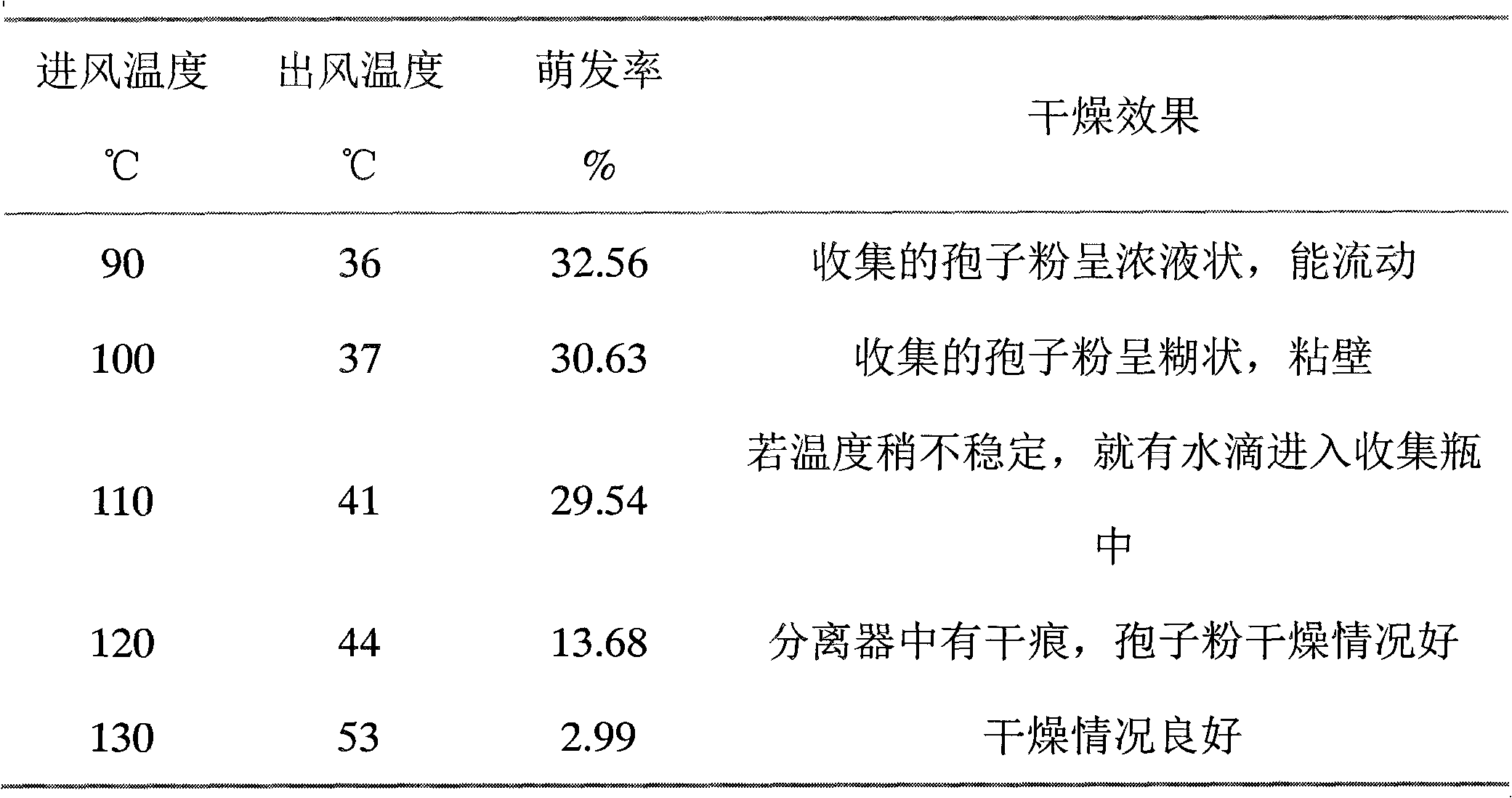

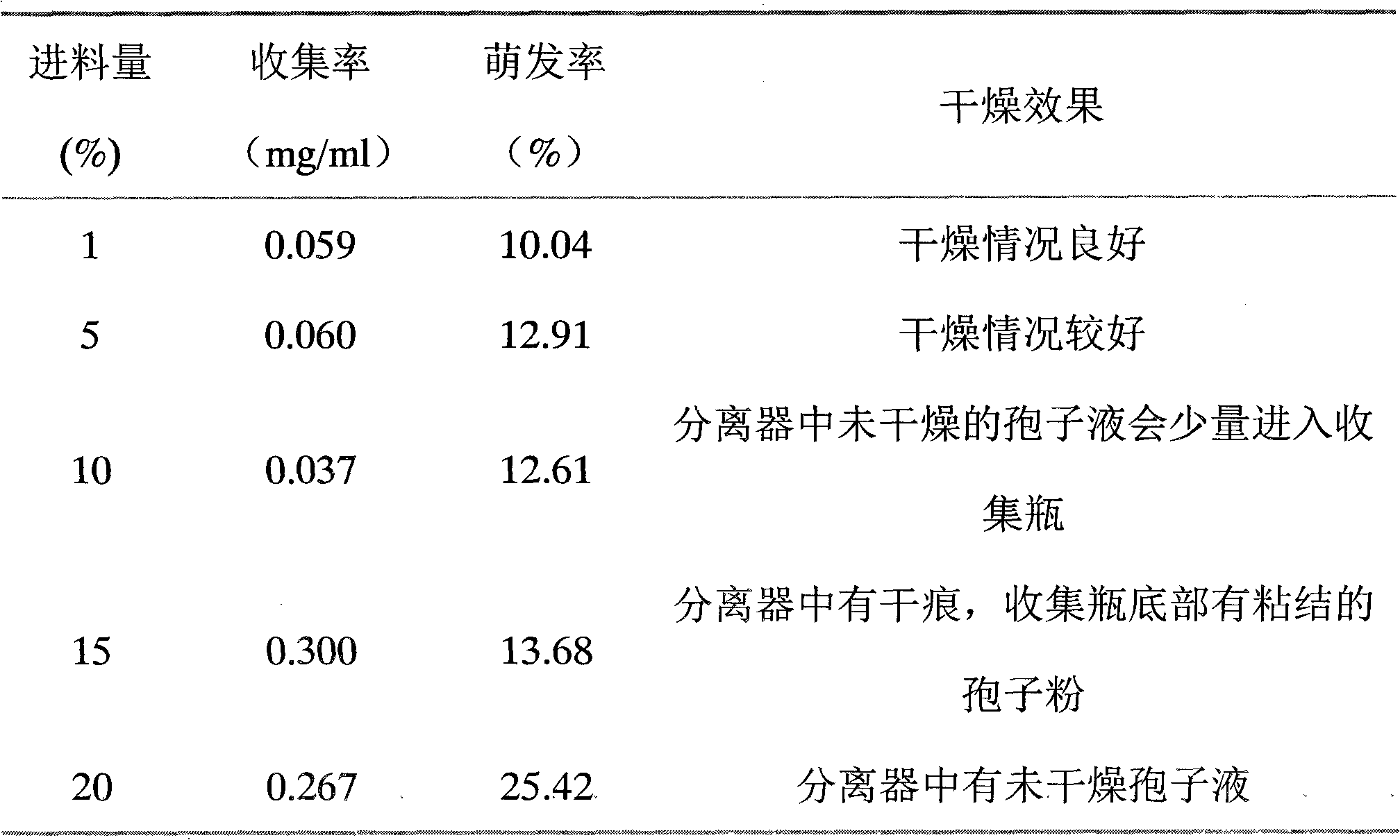

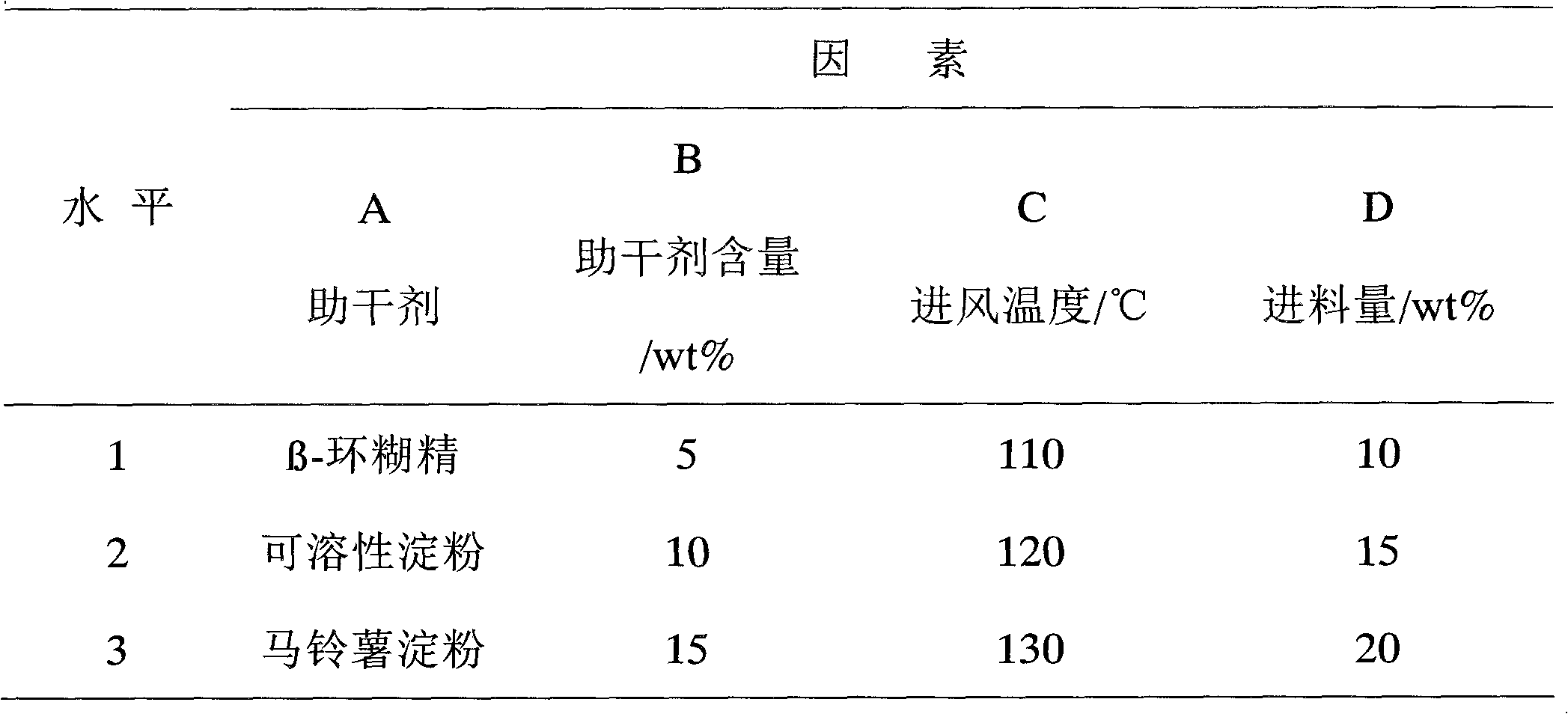

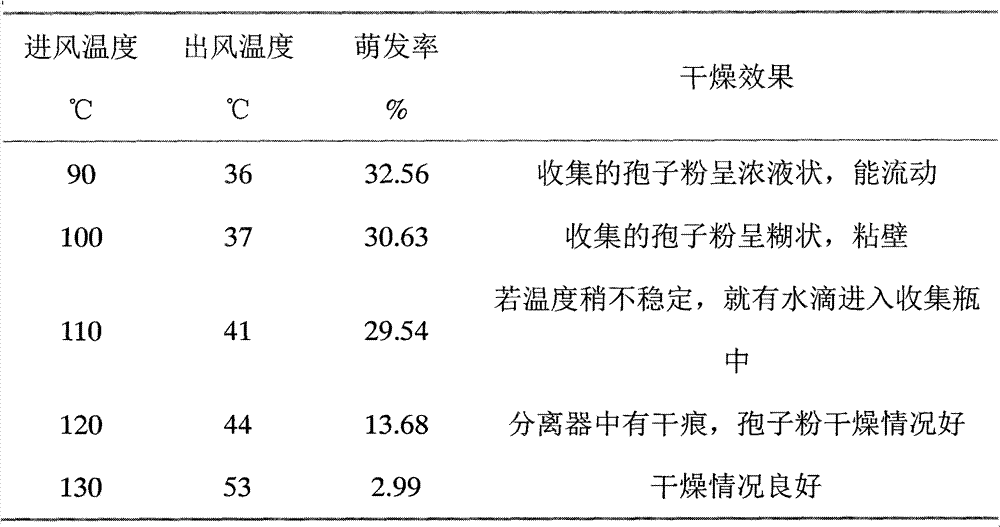

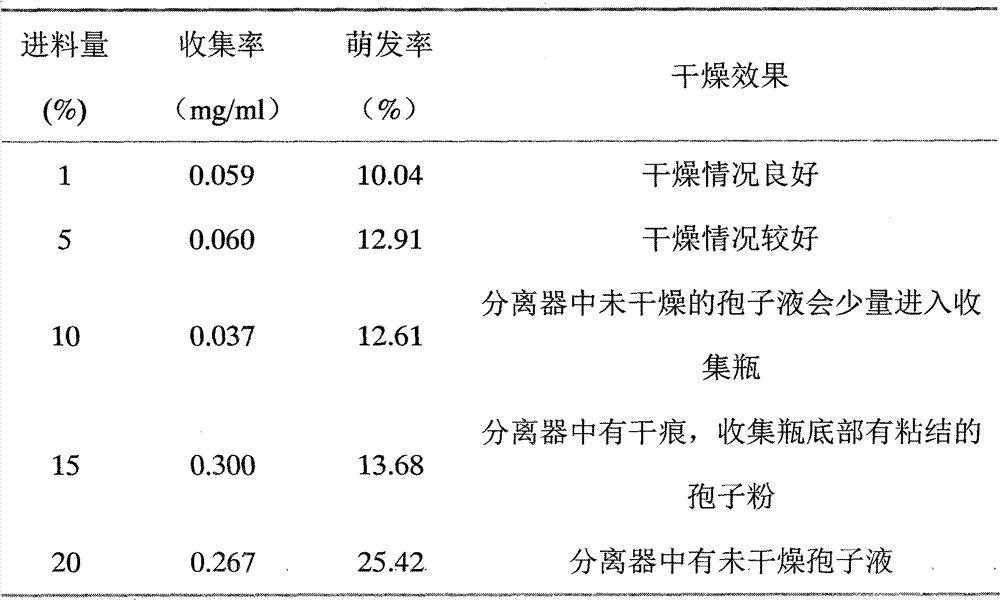

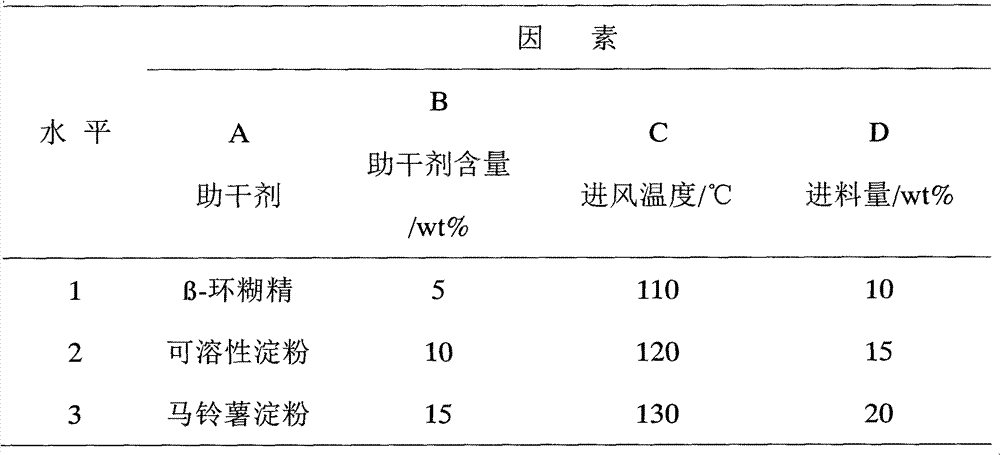

Trichoderma spore powder as well as preparation method and application thereof

InactiveCN102067885AInhibitionTo achieve the effect of preventionBiocideFungicidesMicroorganismSpore

The invention discloses a trichoderma spore powder as well as a preparation method and application thereof. The trichoderma spore powder contains trichoderma spore powder and a drying aid, wherein the trichoderma spore powder is the spore powder of Trichoderma sperellum T1 which is preserved in the general microorganism center of CCCCM (China Committee for Culture Collection of Microorganisms) and has the preservation number of CGMCC NO: 3531 and a rDNA ITS region segment sequence shown in SEQ ID NO:1; the drying aid is one or more of beta-cyclodextrin, potato starch and soluble starch. The trichoderma spore powder has an effective prevention and control effect on banana vasicular wilt, and has a remarkable antagonism effect on various pathogenic funguses, especially on soil-borne funguses. The preparation time is saved with the preparation method of the trichoderma spore powder, which can be used for preparing the trichoderma spore powder which has high density, high germination rateand high drying efficiency and is easy to store, transport and use.

Owner:惠州市南天生物科技有限公司 +2

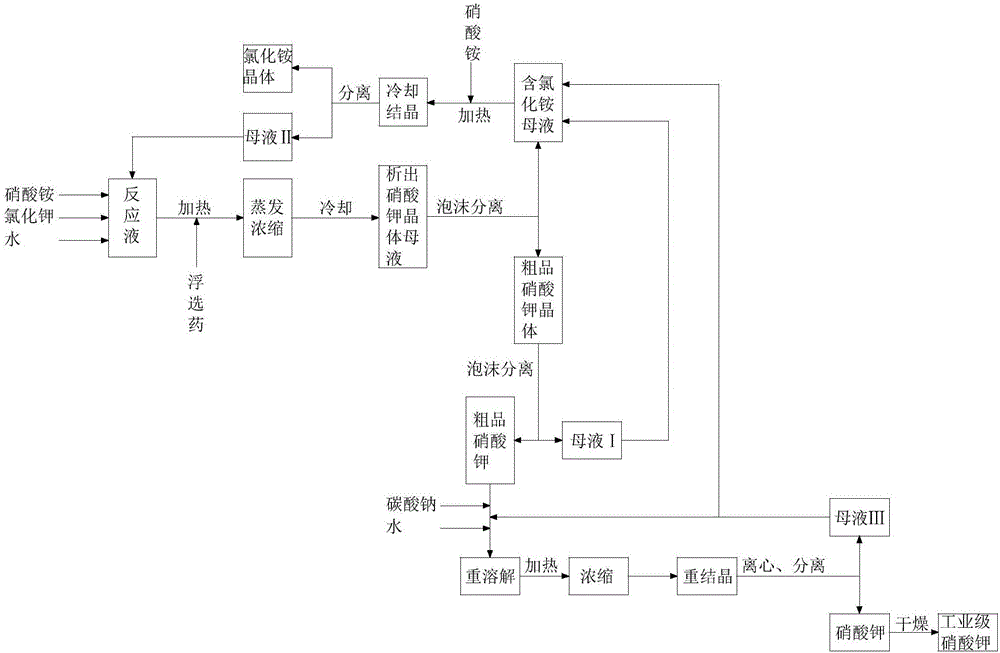

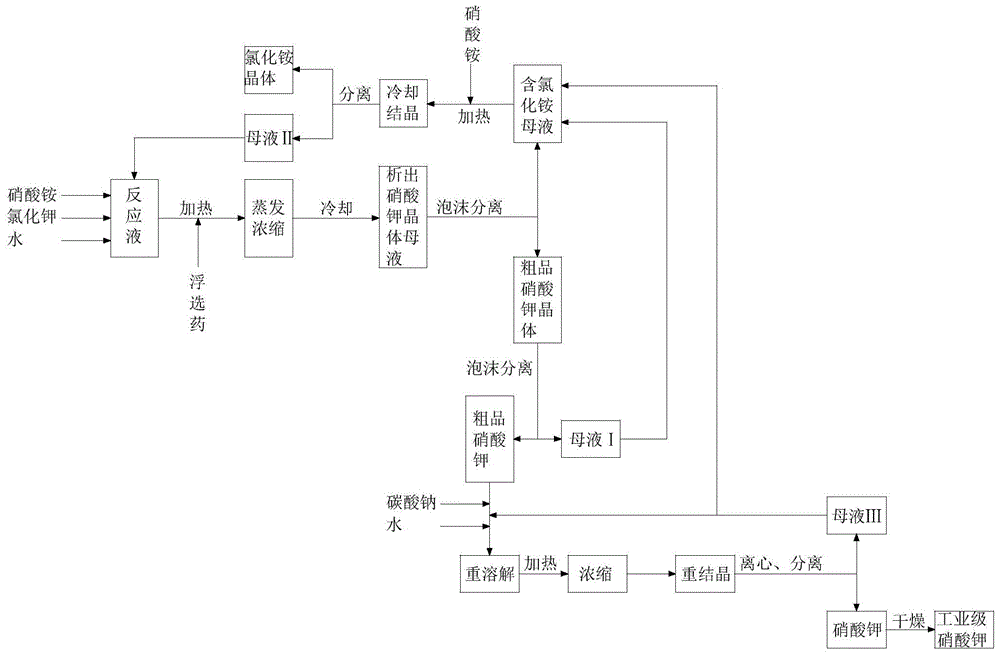

Potassium chloride and ammonium nitrate double decomposition and circulation method for producing high quality potassium nitrate

ActiveCN105060317AHigh quality contentSimple separation processAlkali metal nitrate preparationWater useSeparation technology

The invention discloses a potassium chloride and ammonium nitrate double decomposition and circulation method for producing high quality potassium nitrate. According to the method, potassium chloride and ammonium nitrate are taken as the raw materials, and the method comprises steps of raw material preparation, potassium nitrate crystallization, foam floatation and separation, potassium nitrate refinement, and ammonium chloride crystallization. The method is developed on the basis of conventional potassium nitrate production technology by improving part of the technology; wherein in the foam flotation and separation technology, in the presence of a floatation reagent (C12-C20 higher straight-chain aliphatic amine) and in a certain pH value range, the ammonium chloride and coarse potassium nitrate can be separated through foam entrainment; in the potassium nitrate refinement, the refined potassium mother liquid in the previous circulation is used to wash the coarse potassium nitrate, and then potassium nitrate is purified by sodium carbonate. In one aspect, the conventional potassium nitrate production technology is optimized, the potassium nitrate quality is improved, and the impurity content of the potassium nitrate product is greatly reduced. In the other aspect, the water using amount is reduced, the labor intensity is also reduced, and the production cost is saved. The industrial grade KNO3 mass content is not less than 99.7%, the content of Cl<-> is not more than 0.01%, and the content of NH4<+> is not more than 0.03%. the method has a wide application value and can generate prominent social benefit and economic benefit.

Owner:湖南丹化农资有限公司

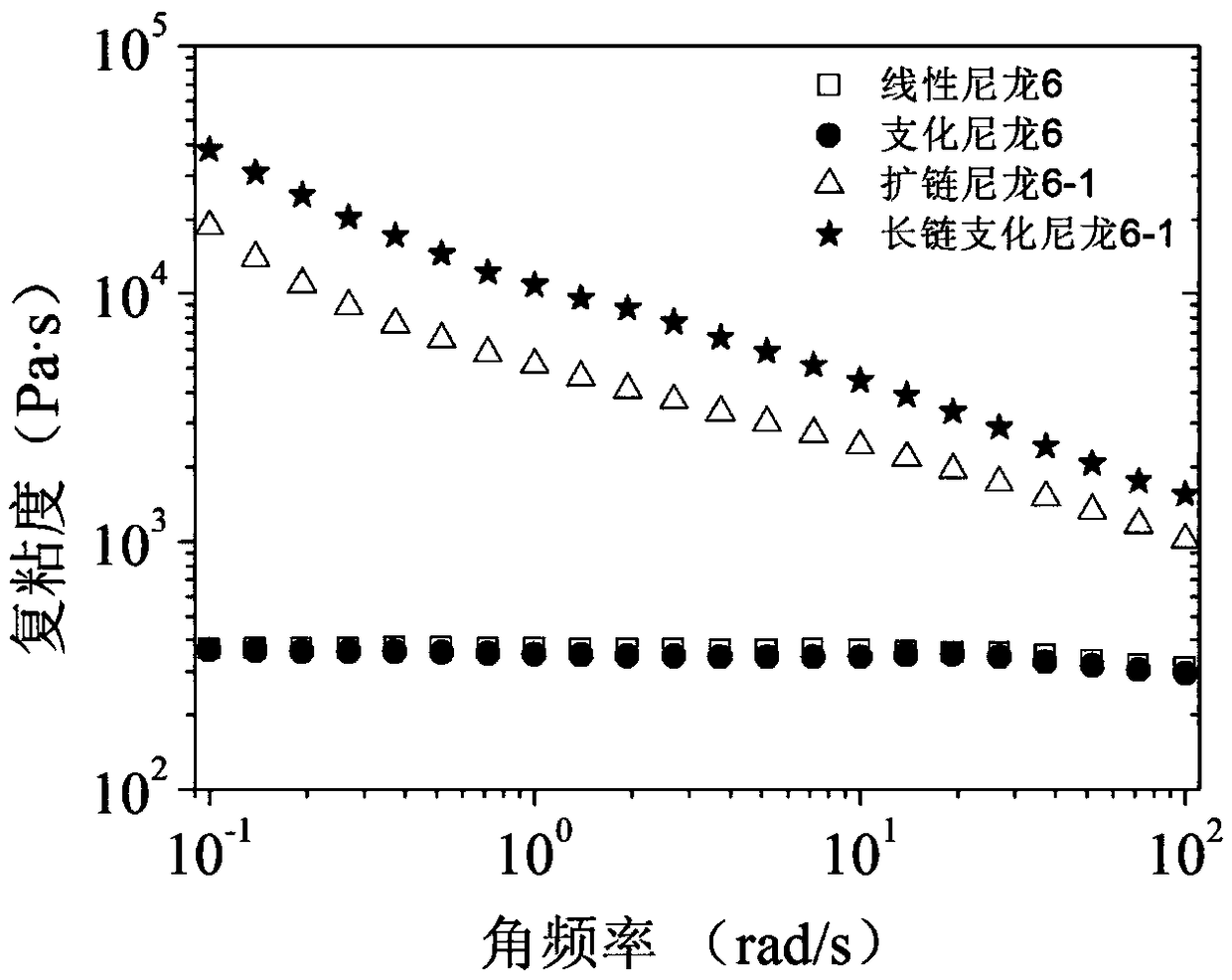

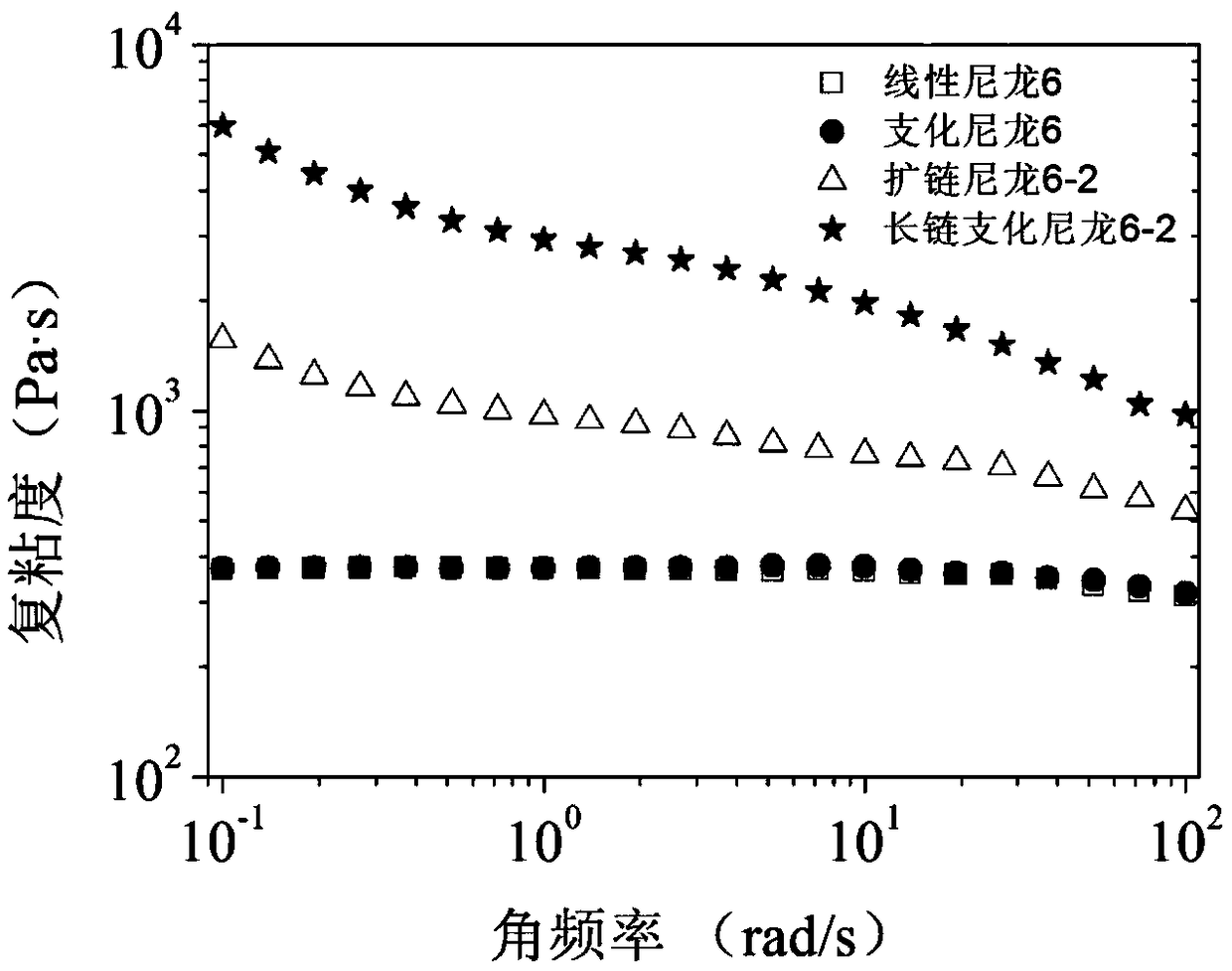

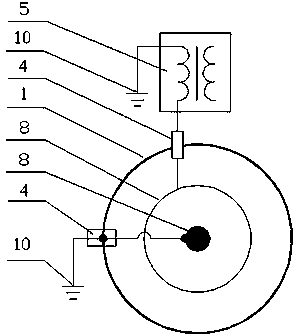

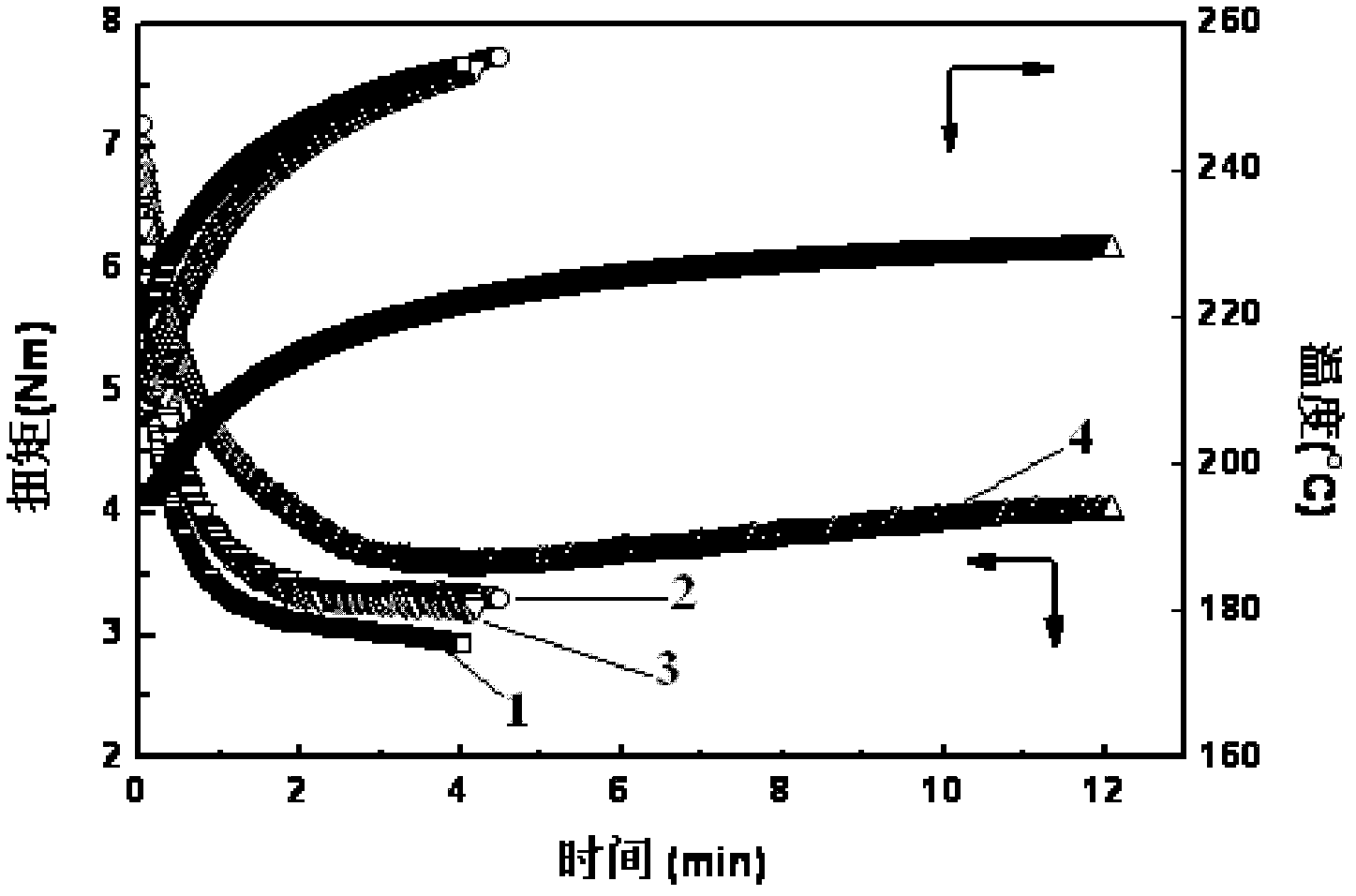

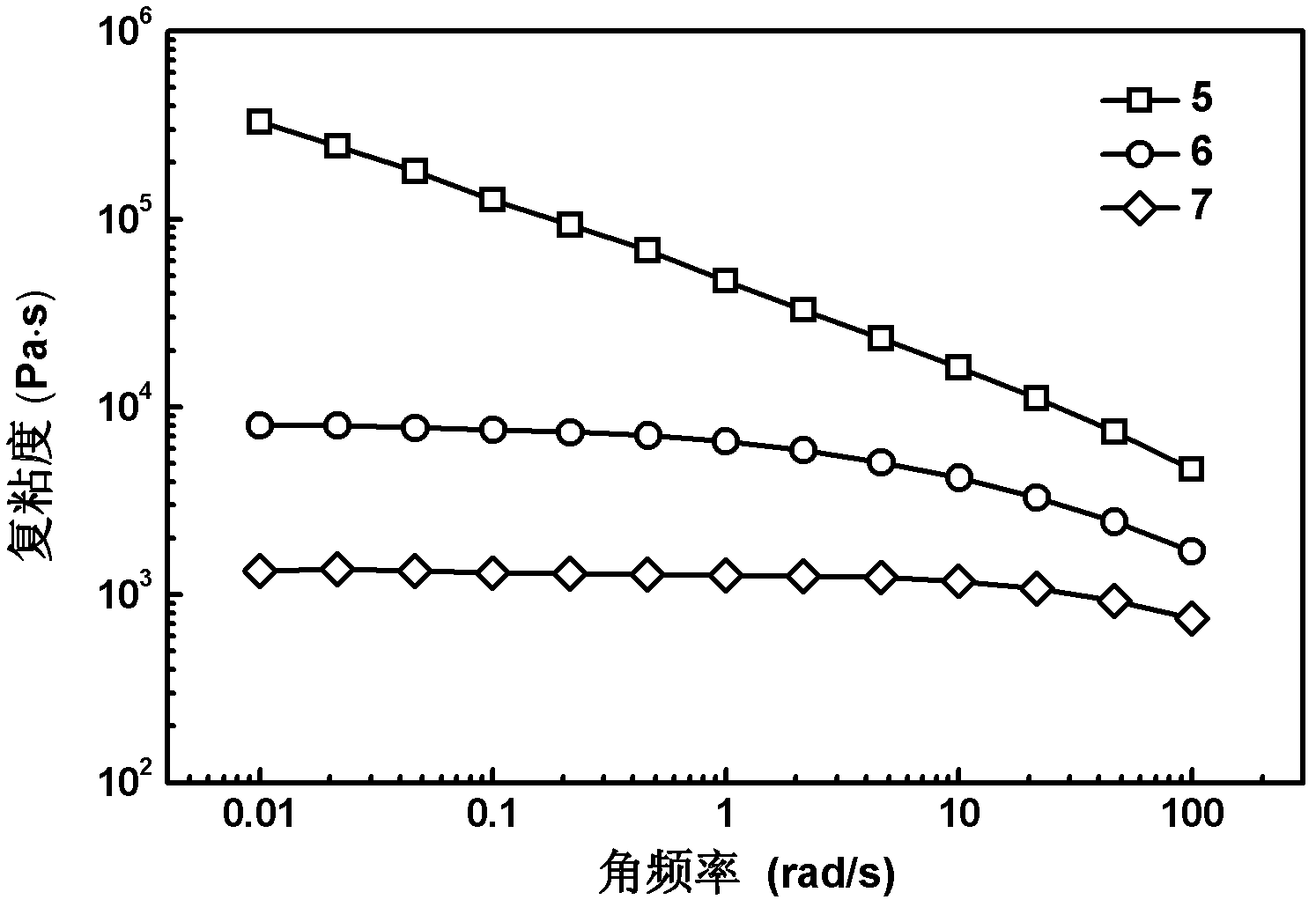

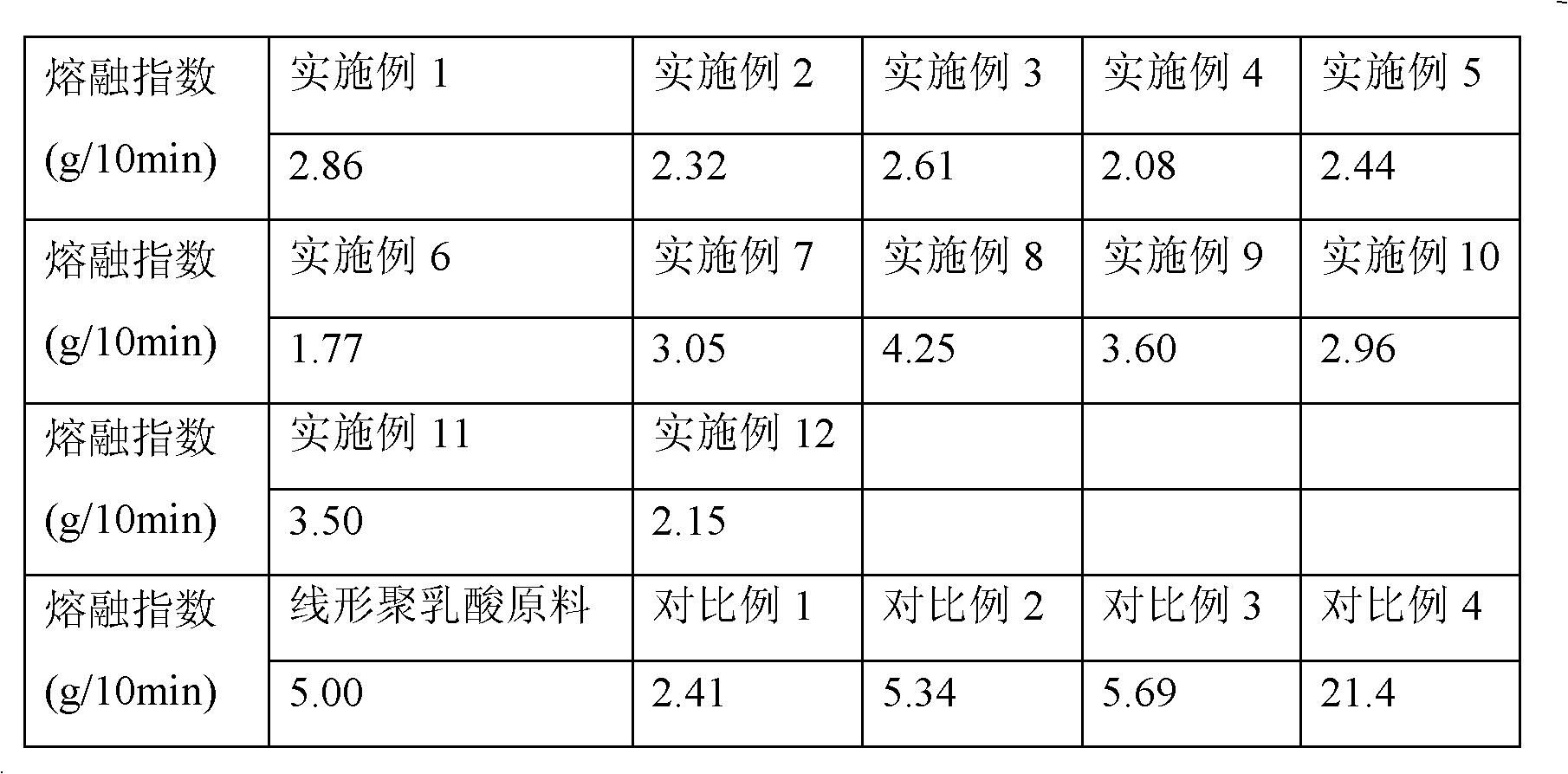

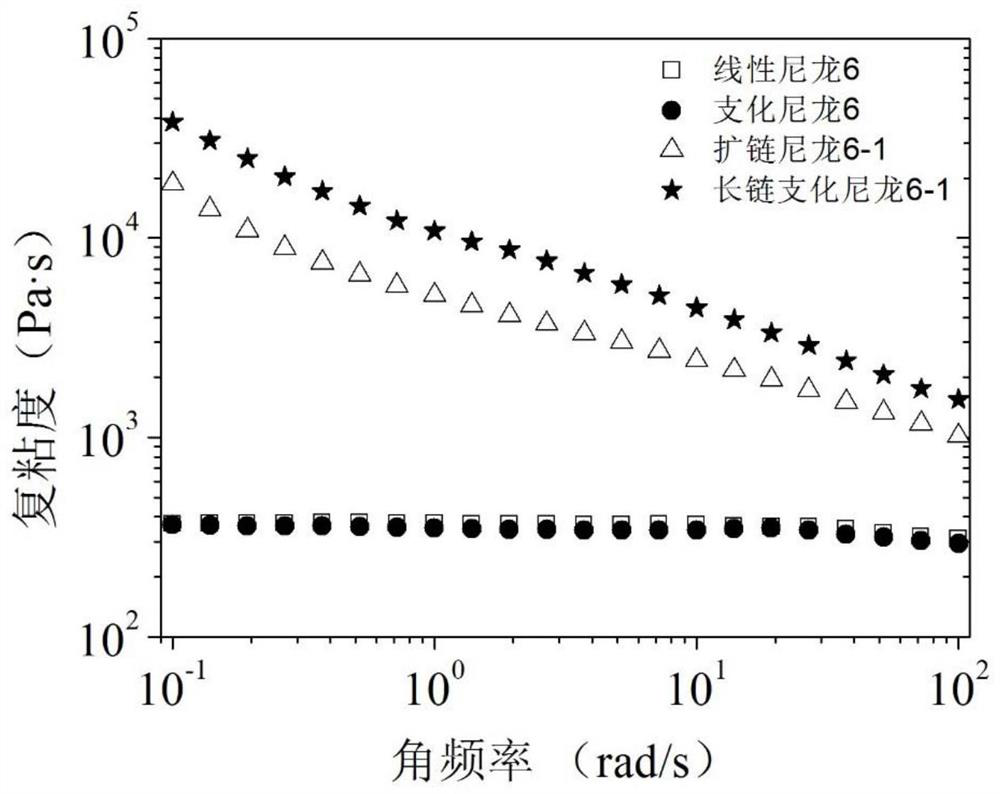

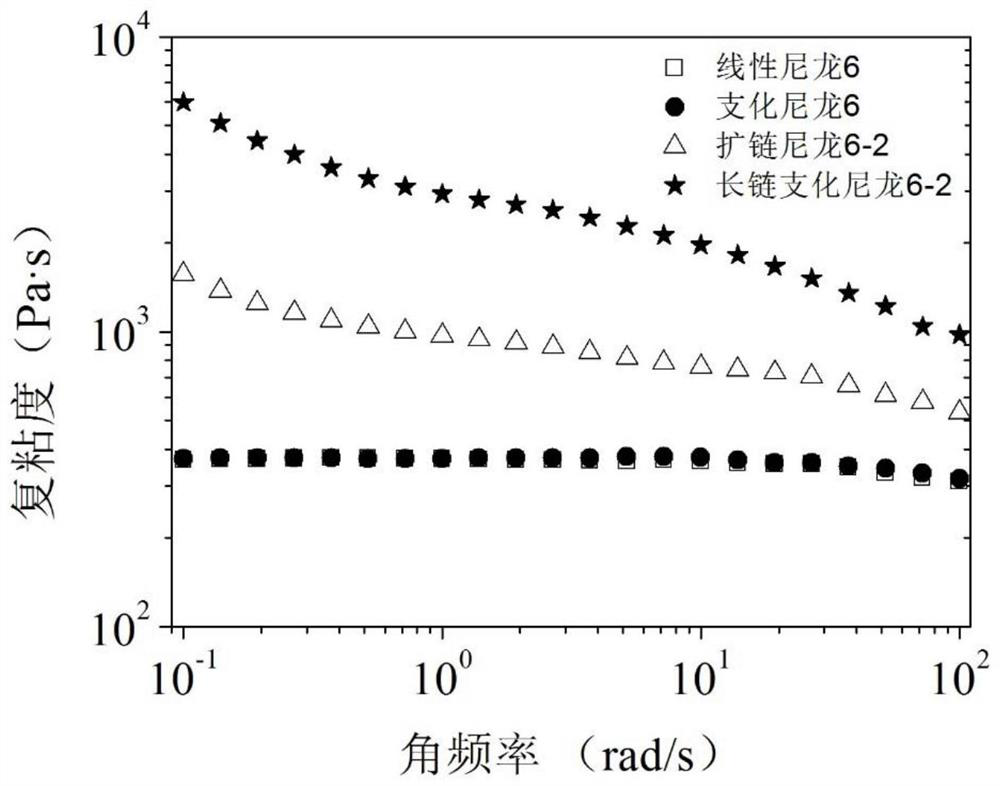

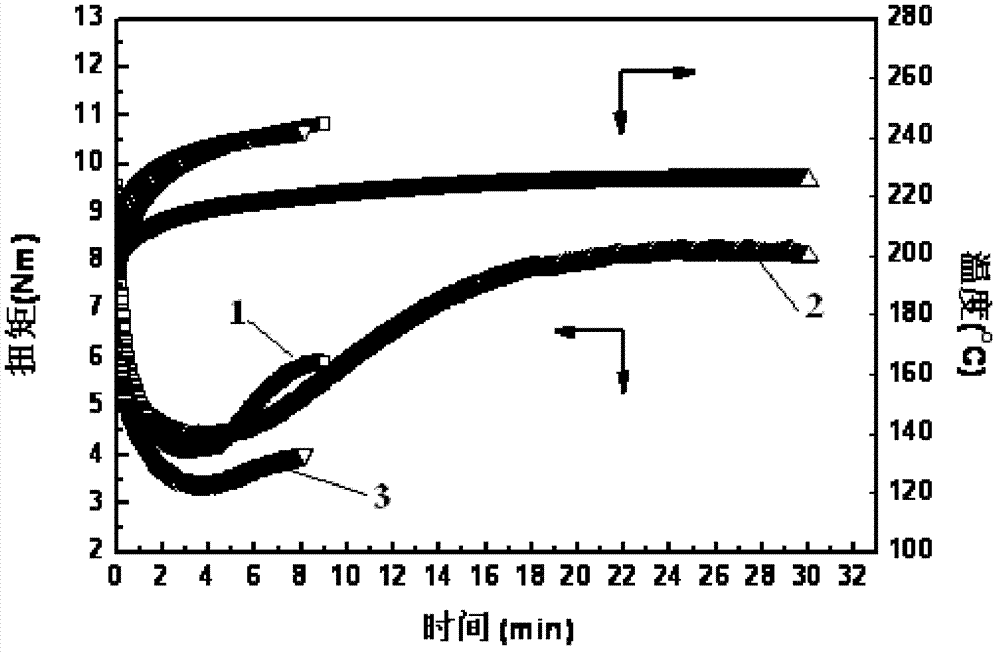

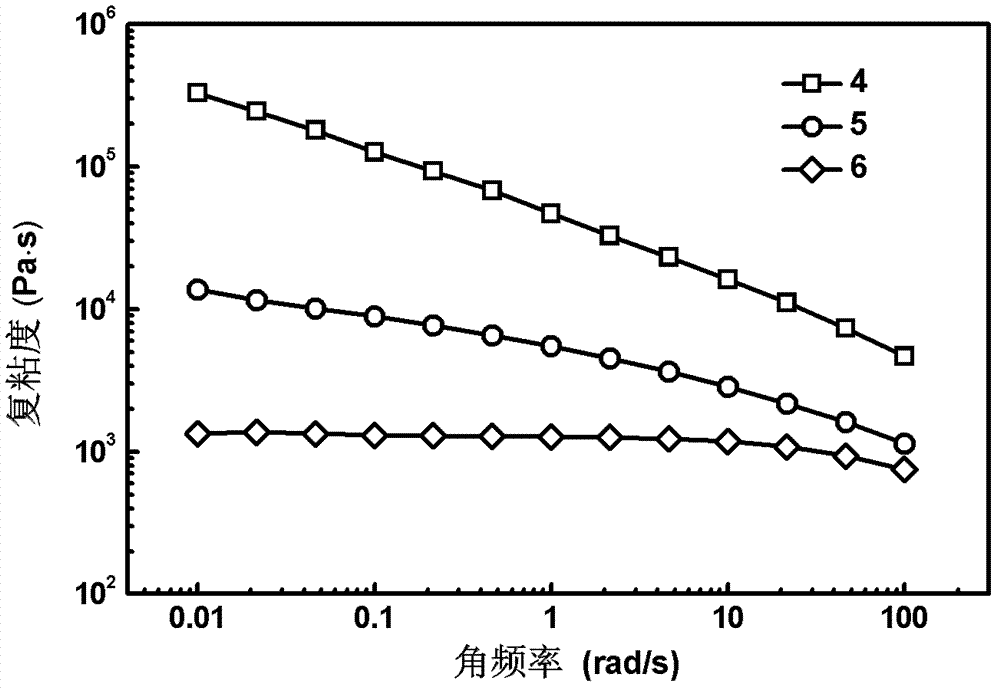

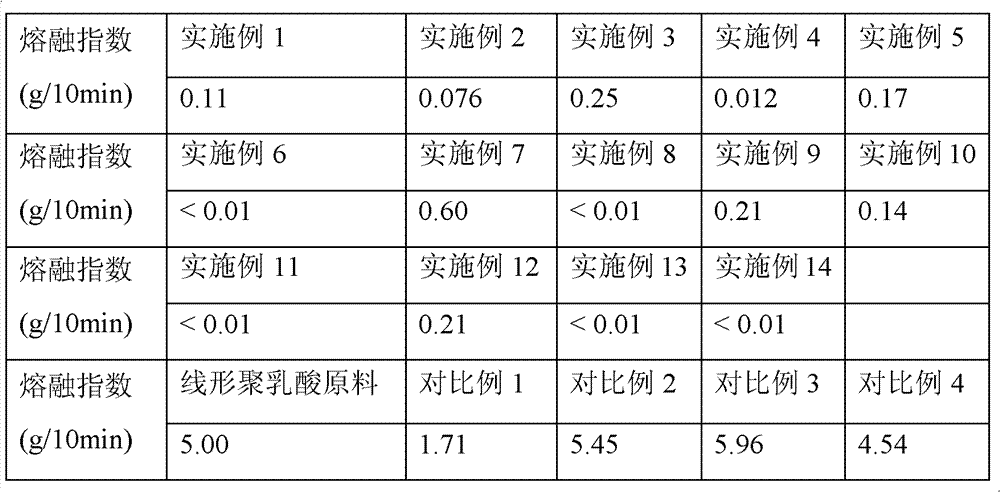

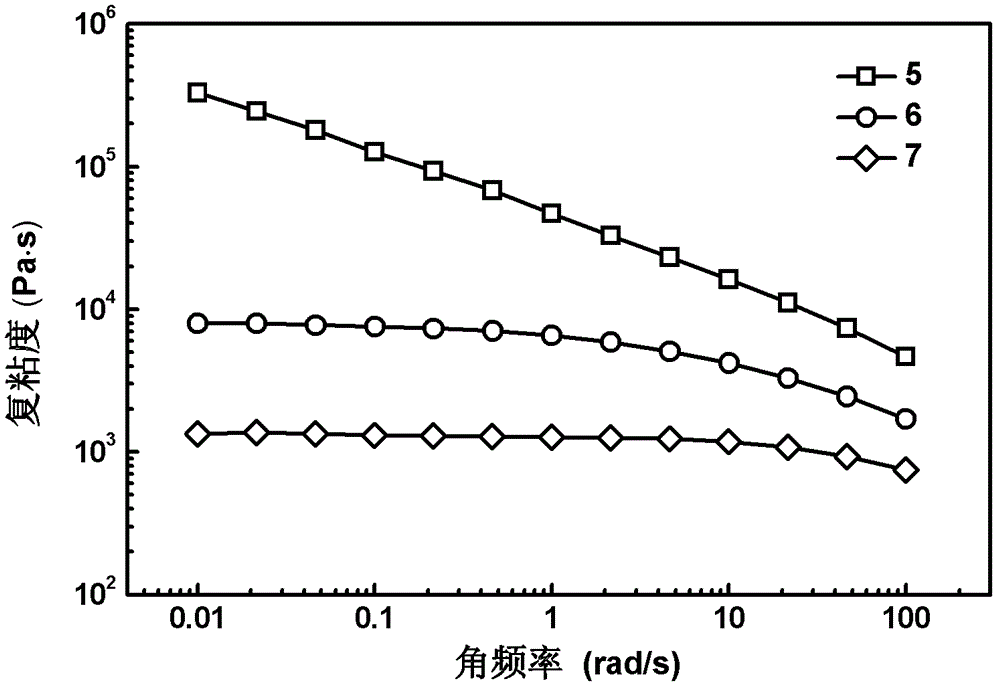

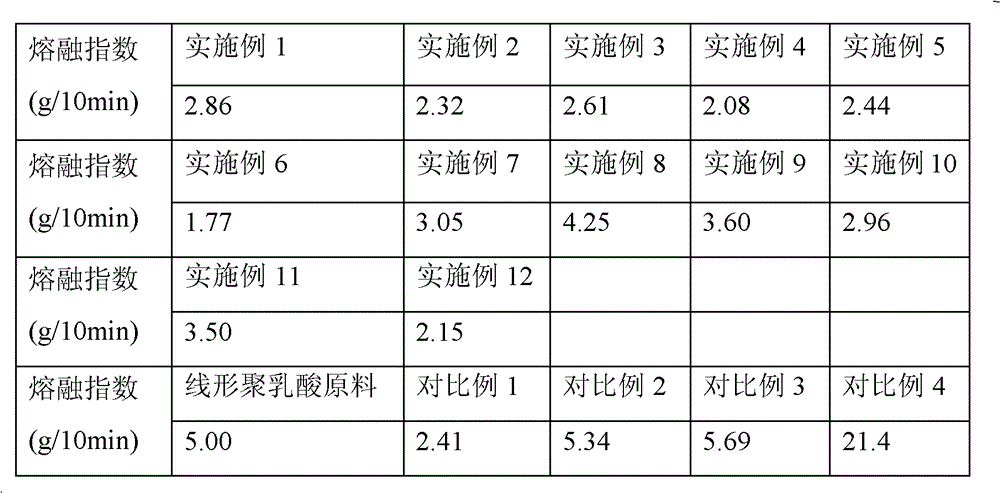

Method for preparing long chain branched polylactic resin by combining two-step functional group reaction

ActiveCN102453250ASignificant branching effectControl the degree of branchingAntioxidantReaction rate

The invention provides a method for preparing long chain branched polylactic resin by combining two-step functional group reaction, and relates to the technical field of polymer processing. The method for preparing the long chain branched polylactic resin by combining two-step functional group reaction comprises the following steps of: (1) melting polylactic resin; (2) adding an antioxidant, anhydride polyfunctional monomers and epoxy polyfunctional monomers, and mixing uniformly; and (3) melting and blending until the reaction is finished to obtain the long chain branched polylactic, whereinbased on 100 weight parts of linear polylactic resin, the antioxidant is 0.1 to 0.5 part, the anhydride polyfunctional monomers are 0.1 to 1 part; and the epoxy polyfunctional monomers are 0.1 to 1 part; and the epoxy polyfunctional monomers have the functionality of more than or equal to 3. By the method, the reaction rate is improved by 5 to 10 times; the obtained long chain branched polylacticproduct has an obvious branching effect, the melt strength and viscosity are greatly improved, and the product material meets the requirement of forming and can be easily subjected to film making, foaming and other processes according to product requirements; and the branching degree and the melt strength of the product can be controlled to a certain extent by regulating a monomer proportion and reaction temperature.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of lacquer tree seed wax oil

InactiveCN103849470AEasy to separateNot easy to stickFatty substance recovery/refiningAgricultural engineeringLacquer tree

The invention discloses a preparation method of lacquer tree seed wax oil. The preparation method comprises the following steps: cooling lacquer tree seeds, rubbing the seeds, screening, crushing, pneumatically conveying and selecting, cooking, solvent extracting, filtering, separating and finally obtaining the lacquer tree seed wax oil. The preparation method of the lacquer tree seed wax oil can enable preparation, extraction and separation of the lacquer tree seed wax oil to be continuous, improves production efficiency, material utilization rate and wax quality, and improves wax market competitiveness. By applying the method, the husk-core separating efficiency of the lacquer tree seeds reaches over 95%, and the lacquer tree seed core perfectness ratio reaches over 90%; and moreover, compared with the existing separating method, the whole set of process flow is reliable in operation and strong in economical efficiency, so that processing cost for per tonnage of seeds is lowered by over 15%.

Owner:云南省轻工业科学研究院有限公司 +1

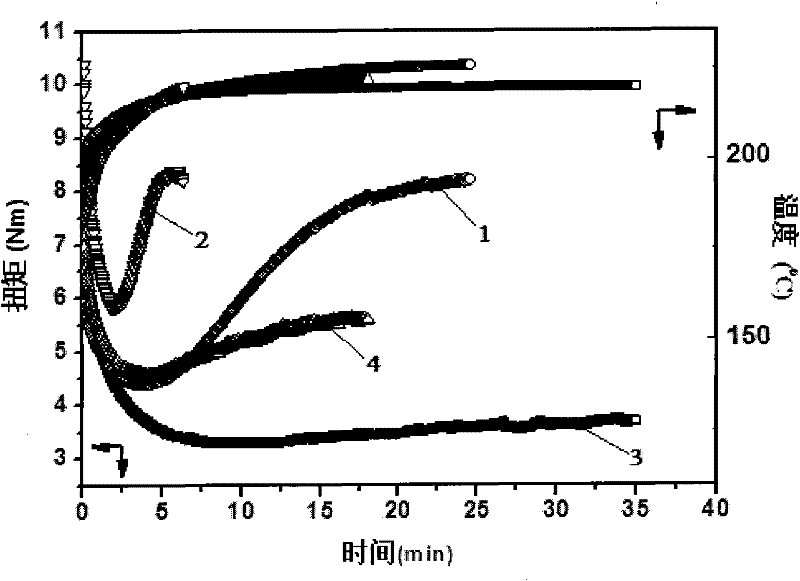

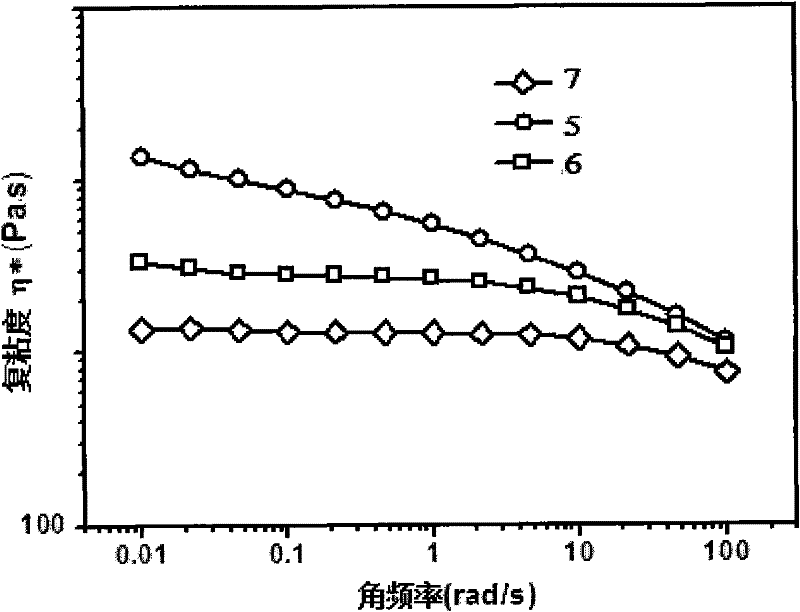

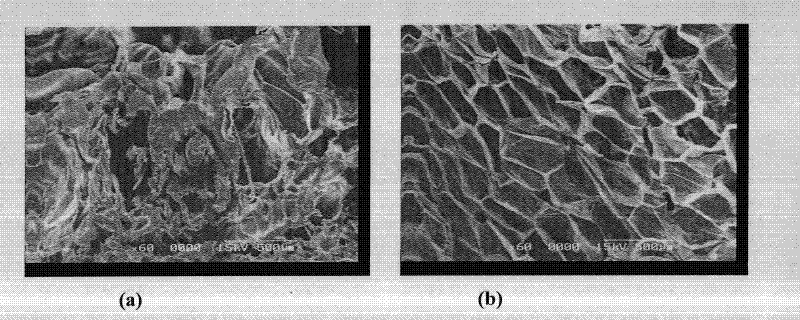

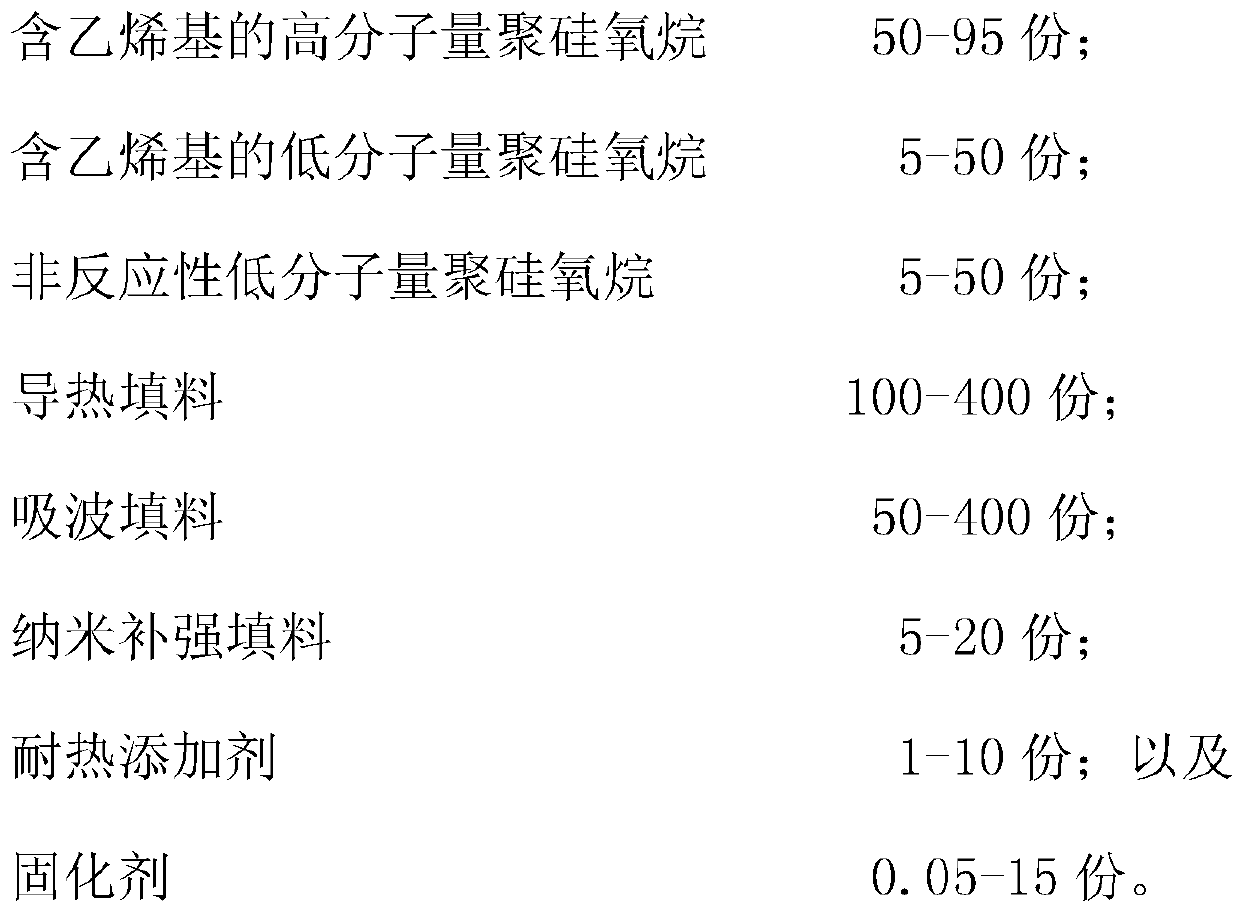

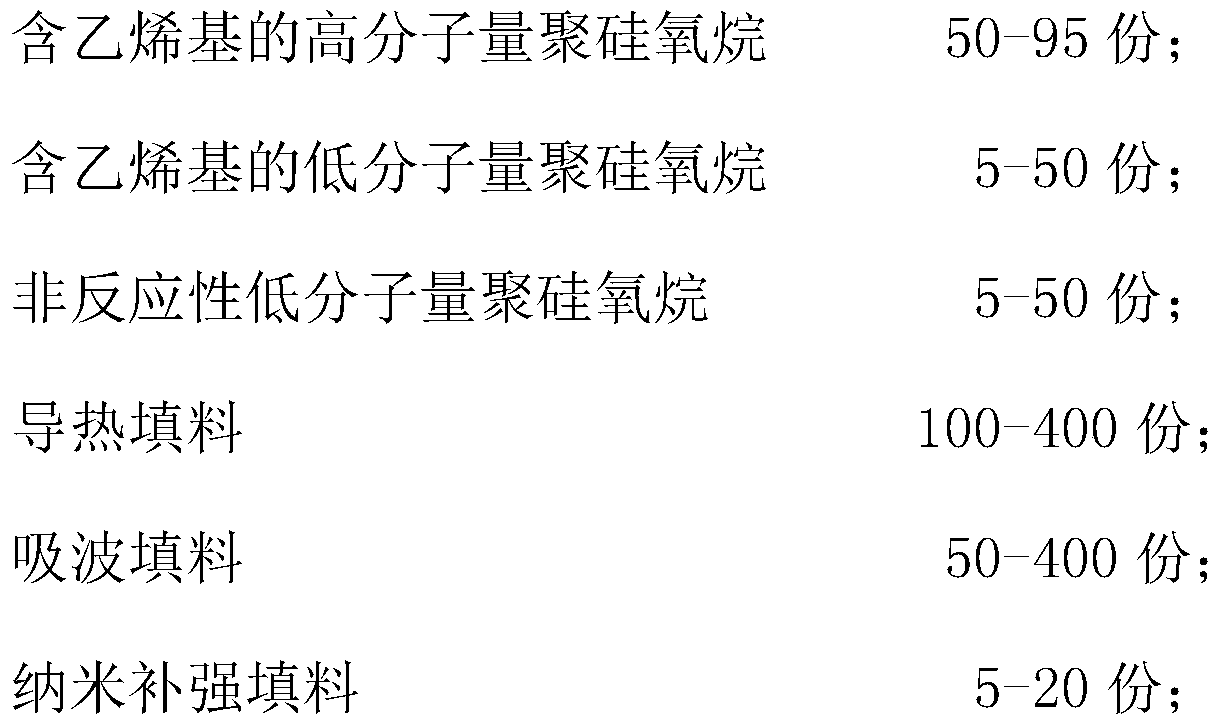

High thermal conductivity wave-absorbing organosilicon composition and preparation method thereof

InactiveCN110294939AImprove thermal conductivityEasy to operateElectromagnetic shieldingUltimate tensile strength

The invention discloses a high thermal conductivity wave-absorbing organosilicon composition and a preparation method thereof. The high thermal conductivity wave-absorbing organosilicon composition isprepared from the following raw materials in parts by mass: 50-95 parts of vinyl-containing high molecular weight polysiloxane, 5-50 parts of vinyl-containing low molecular weight polysiloxane, 5-50parts of non-reactive low molecular weight polysiloxane, 100-400 parts of thermal conductive filler, 50-400 parts of wave-absorbing filler, 5-20 parts of nano reinforcing filler, 1-10 parts of a heat-resistant additive and 0.05-15 parts of a curing agent. The high thermal conductivity wave-absorbing organosilicon composition provided by the invention increases the thermal conductivity by aligningthe sheet-like thermal conductive filler, realizes electromagnetic shielding and wave absorbing of the composition by using the wave-absorbing filler with electromagnetic shielding and wave absorbingeffects, and improves the physical properties of the composition by adding the nano reinforcing filler. The obtained composition has a thermal conductivity greater than 10W / (m.K), a shielding effectiveness greater than 30dB, a tensile strength greater than 0.3MPa and an elongation at break greater than 80%.

Owner:SHENZHEN FRD SCI & TECH

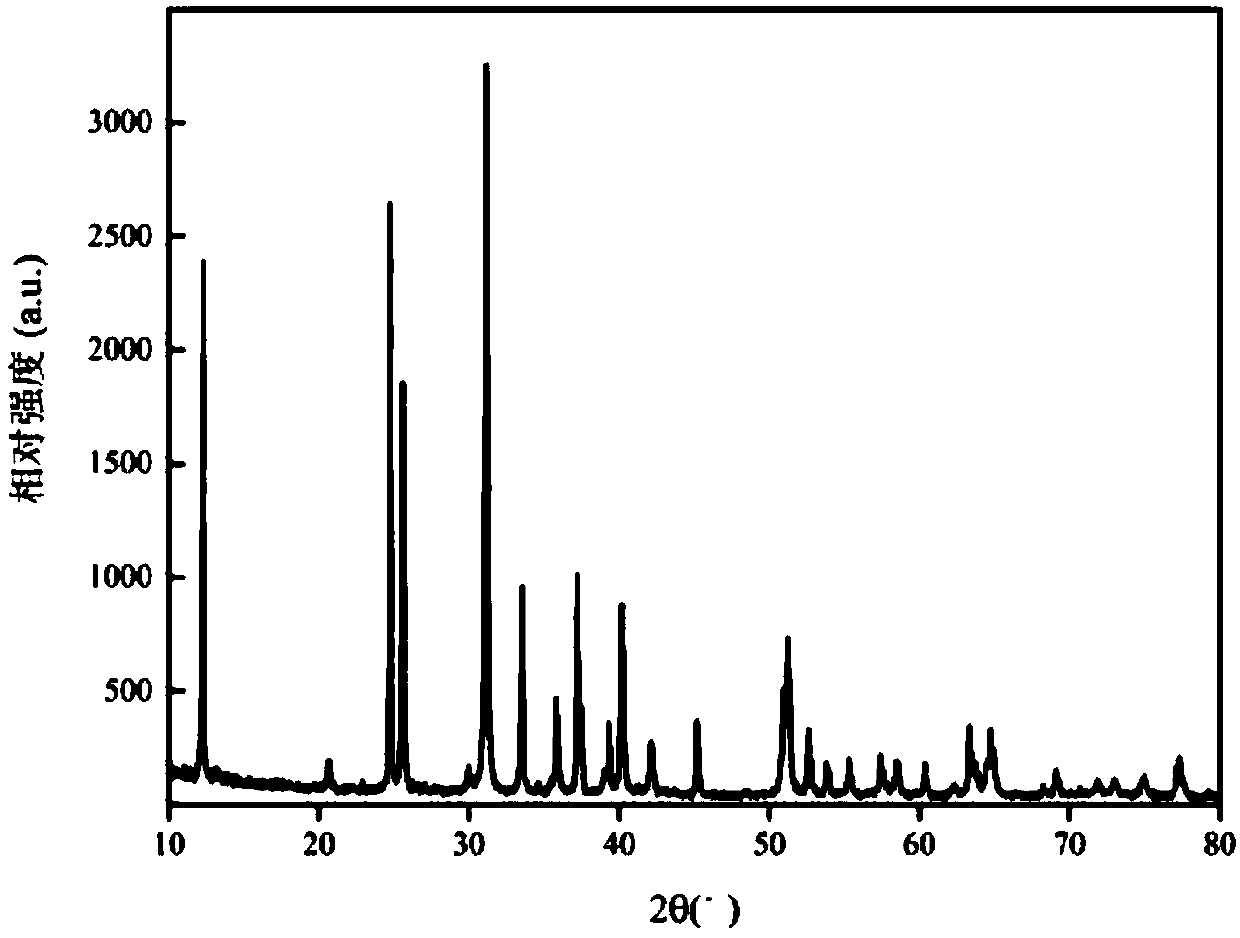

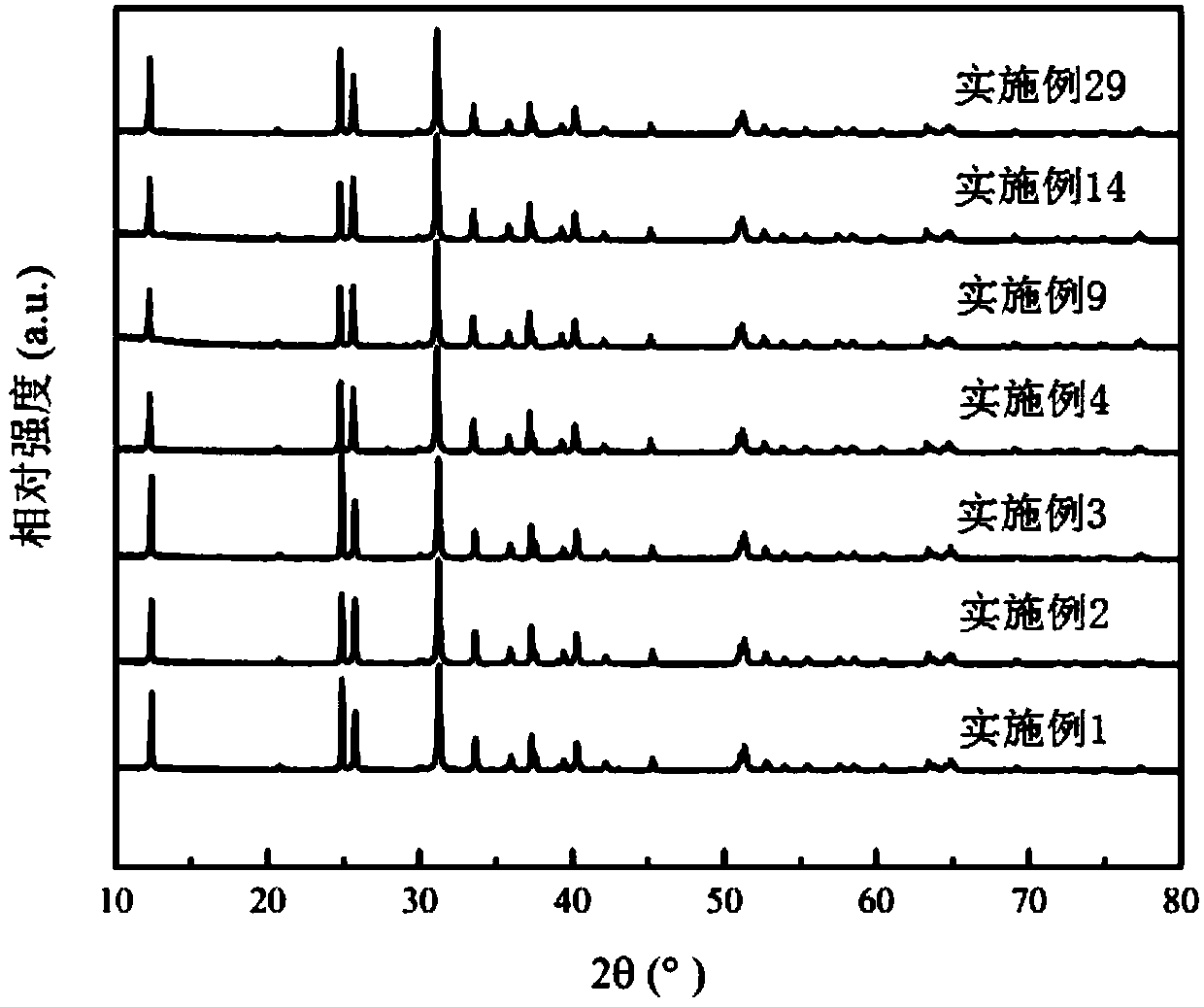

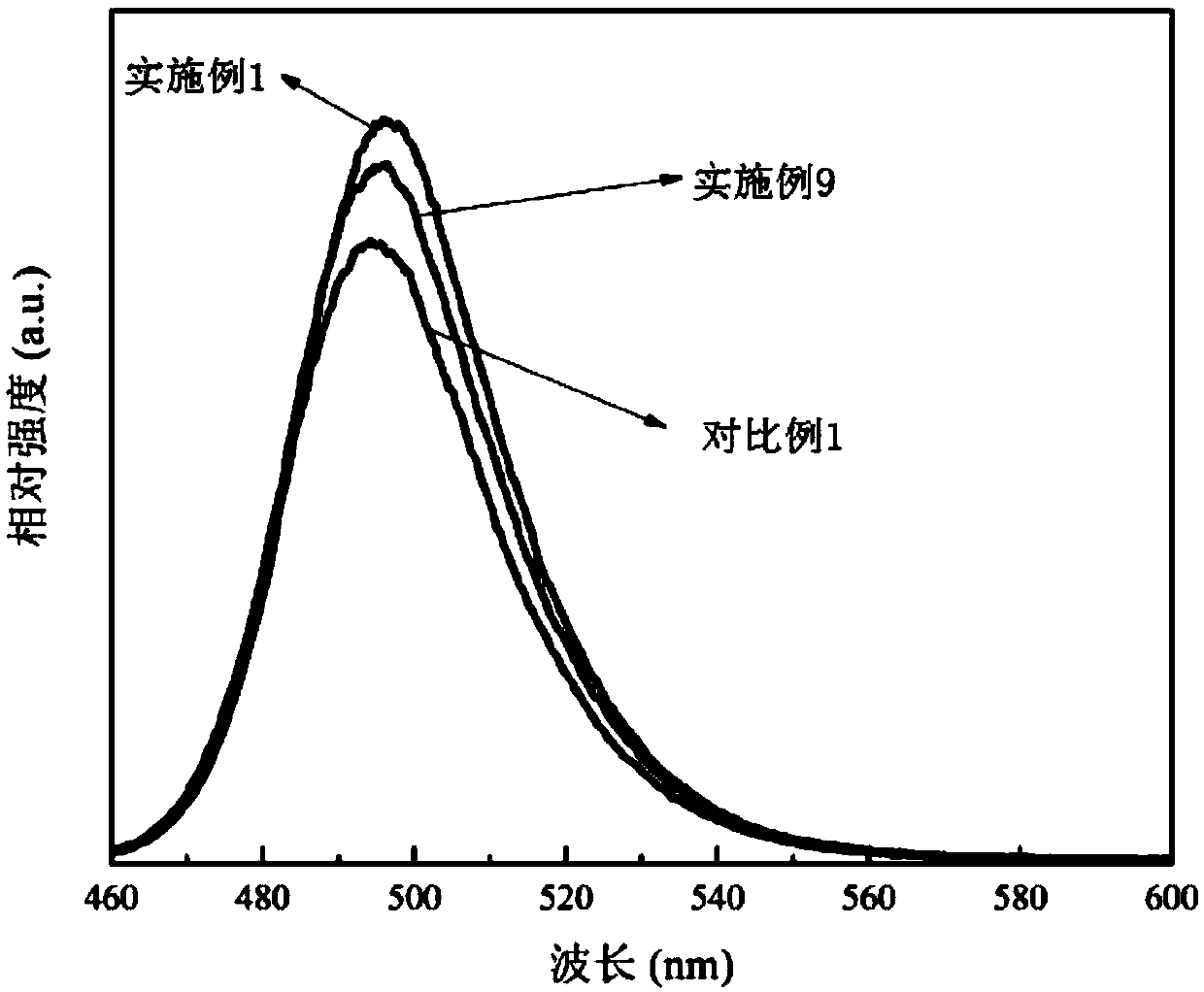

Fluorescence-enhanced silicon-based nitrogen oxide cyan fluorescent powder, and preparation method thereof

InactiveCN107722982AHigh luminous intensityHigh reactivityLuminescent compositionsFluorescenceNitrogen oxide

The invention discloses a fluorescence-enhanced silicon-based nitrogen oxide cyan fluorescent powder, and a preparation method thereof, and belongs to the technical field of luminescent material. Thepreparation method is used for solving a problem in the prior art that the fluorescent brightness of BaSi<2>O<2>N<2>:Eu<2+> nitrogen oxide is low. The chemical formula of the fluorescence-enhanced silicon-based nitrogen oxide cyan fluorescent powder is (Ba<1-x-y-z-m>M<x>R<y>A<z>)O*0.5SiO<2>*0.5Si<3>N<4>:mEu<2+>, wherein 0.01<=m<=0.05, 0<=x<=0.2, 0.005<=y<=0.2, 0.5<=y / z<=1, 0<x+y+z<0.5, R is used for representing at least one element selected from La, Y, Tb, Dy, Ho, Er, Tm, Yb, Lu, Bi, Pr, and Mn, M is used for representing at least one element selected from Ca, Sr, and Mg, A is used for representing at least one element selected from K, Na, and Li. The fluorescent brightness of the fluorescence-enhanced silicon-based nitrogen oxide cyan fluorescent powder is high, and the excitation peak value is stabilized at 490 to 500nm under blue light excitation.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

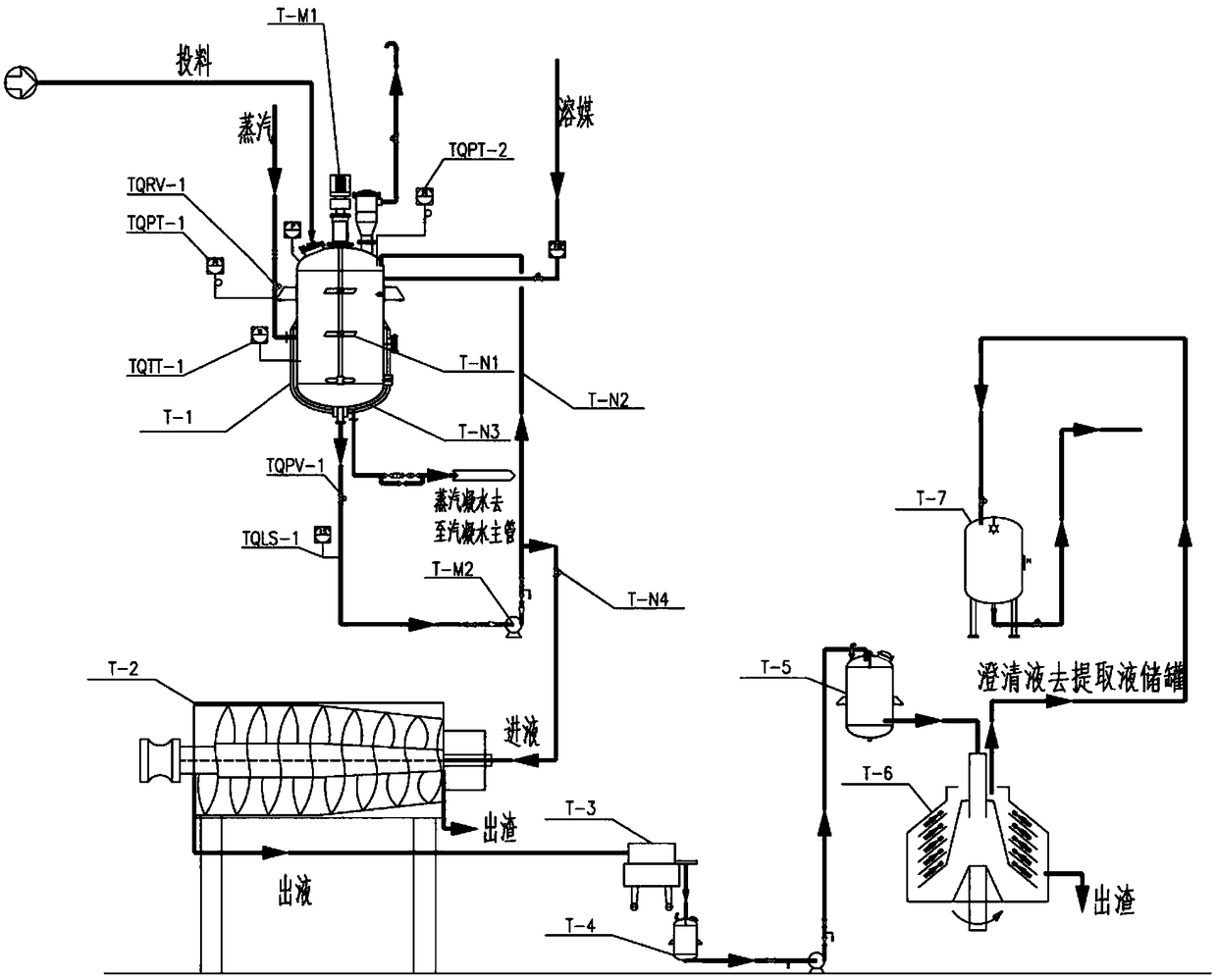

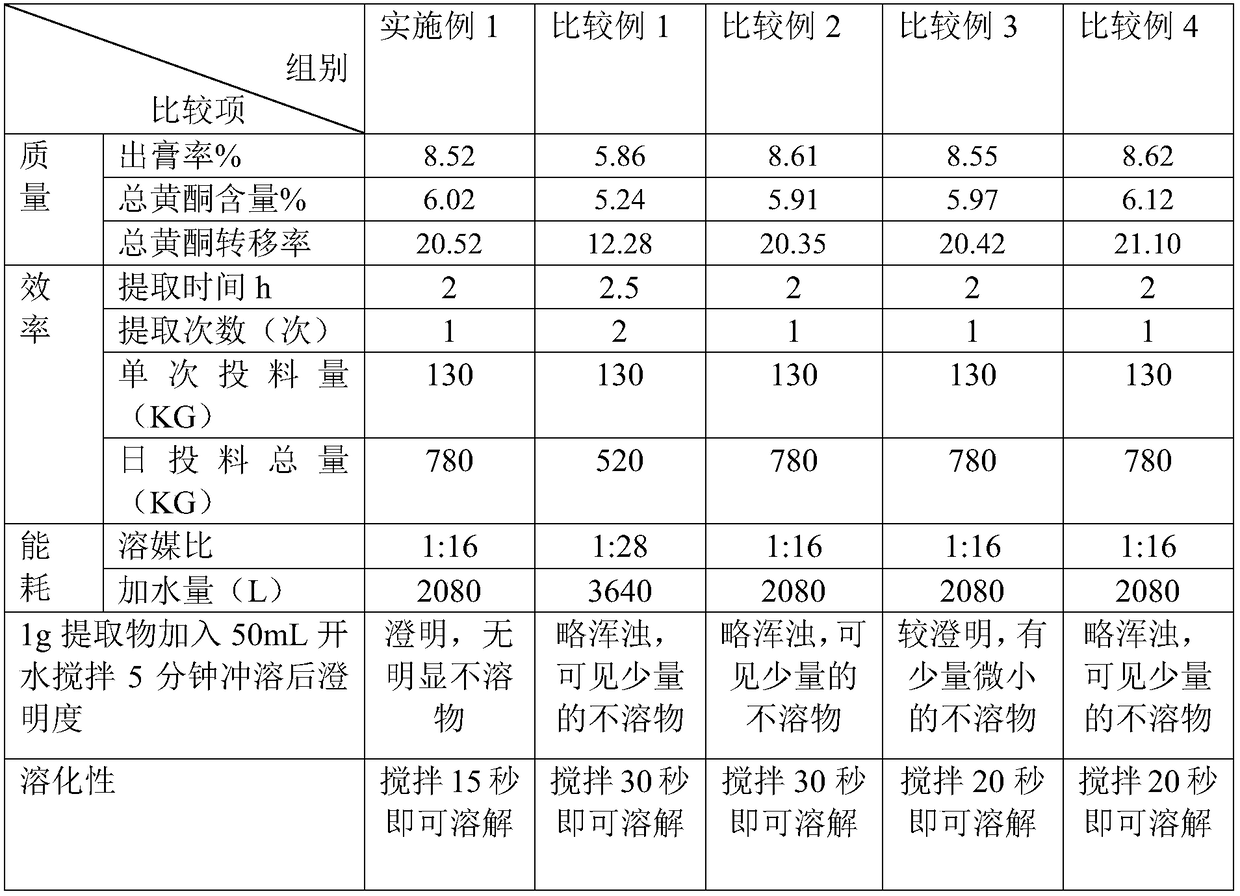

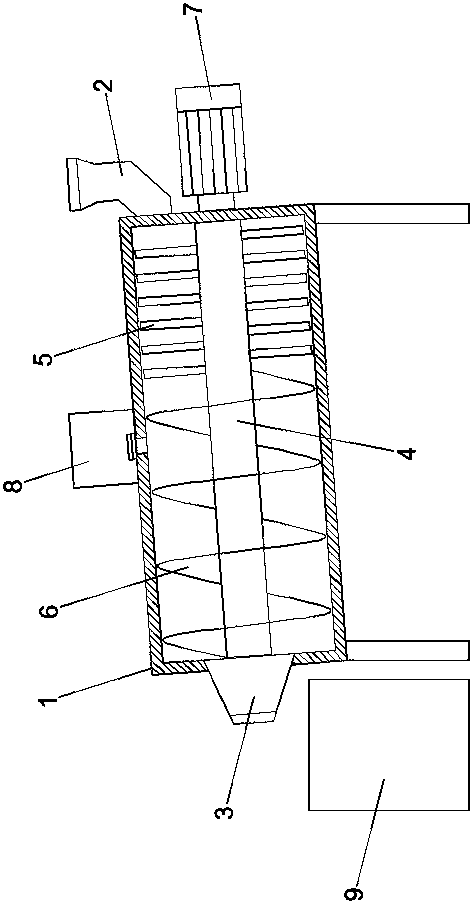

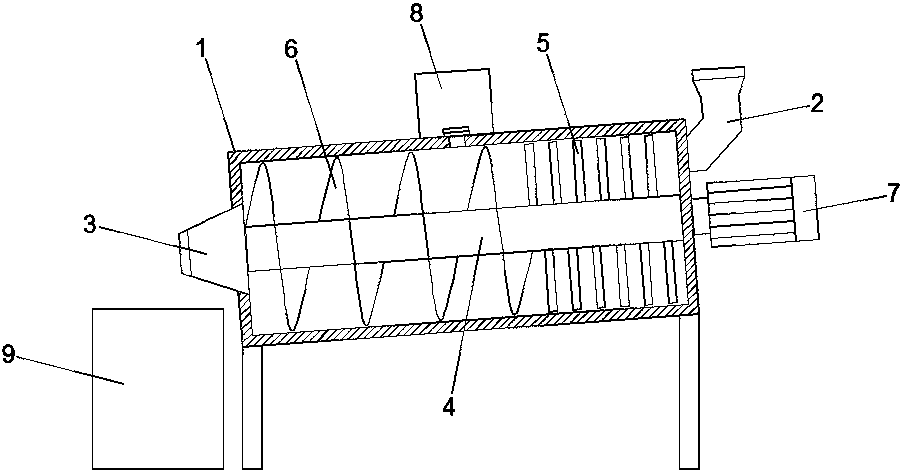

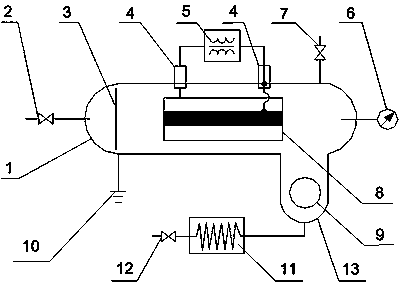

Traditional Chinese medicine automatic extraction and separation device and extraction and separation method and application thereof

PendingCN109126191ADissolves quicklySolve easy blockageSolid solvent extractionFiltration circuitsFiltrationSeparation method

The invention relates to a traditional Chinese medicine automatic extraction and separation device and an extraction and separation method and an application thereof. The traditional Chinese medicineautomatic extraction and separation device is characterized in that the extraction and separation device comprises a dynamic extraction tank and a combined solid-liquid separation module; after extraction, extraction solution and dregs in the dynamic extraction tank are introduced into the combined solid-liquid separation module for solid-liquid separation; the combined solid-liquid separation module comprises three solid-liquid separation devices. The traditional Chinese medicine automatic extraction and separation device has the advantages of improving the adaptability of traditional Chinesemedicine extraction and the filtration efficiency of traditional Chinese medicine extracts, strengthening separation, and reducing production cost and consumption.

Owner:JIANGYIN TIANJIANG PHARMA

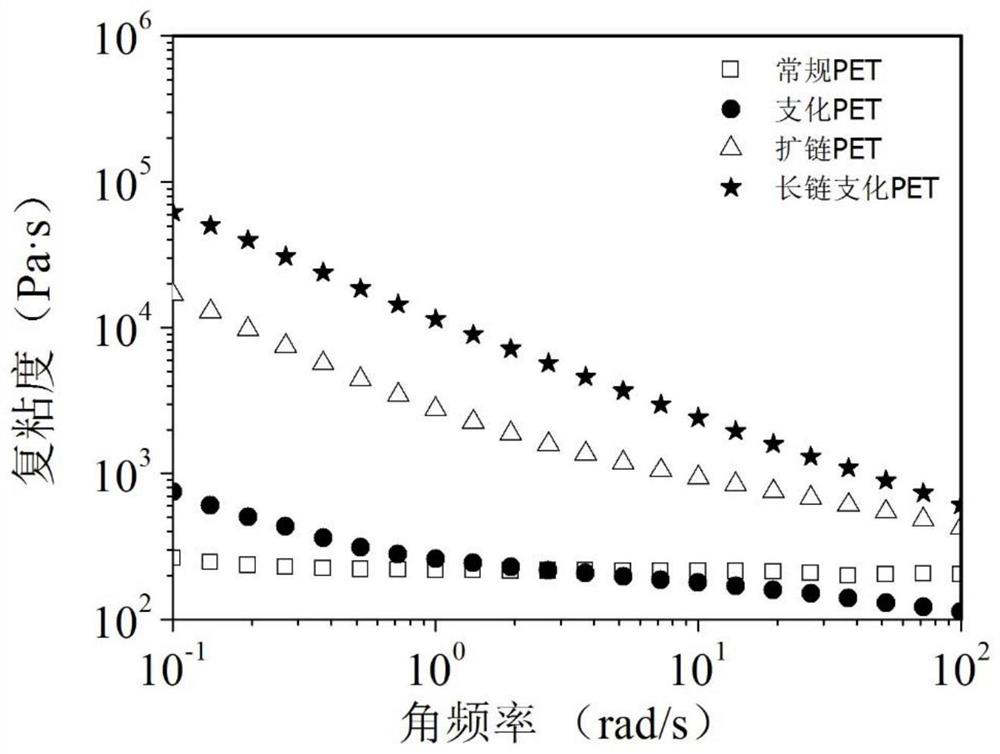

Modified resin, raw material composition, preparation method, foaming material and application

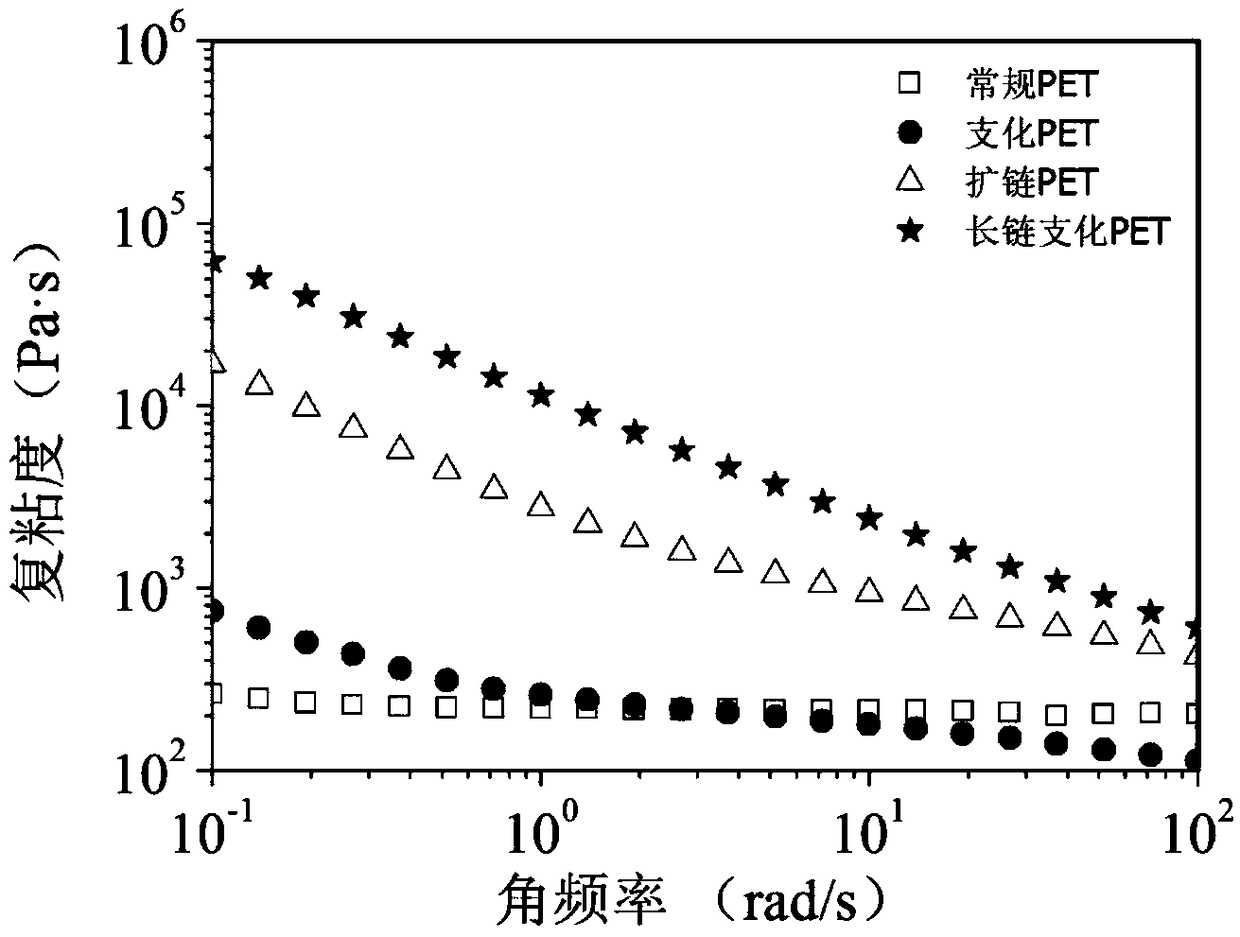

ActiveCN108976427ASignificant stretch hardeningHigh molecular weightUltimate tensile strengthPolyresin

The invention discloses modified resin, raw material composition, preparation method, foaming material and application. The raw material composition is prepared from resin and an epoxy polyfunctionalmonomer with the weight ratio of 100 to (0.5 to 5), the resin is linear resin of which the active group is located at chain terminal group. According to the invention, the resin of which the active group is located at chain terminal group is convenient and efficient to modify by functional group reaction, the prepared modified resin has high melt strength, and can achieve good foaming, blowing film processing and molding effects.

Owner:EAST CHINA UNIV OF SCI & TECH

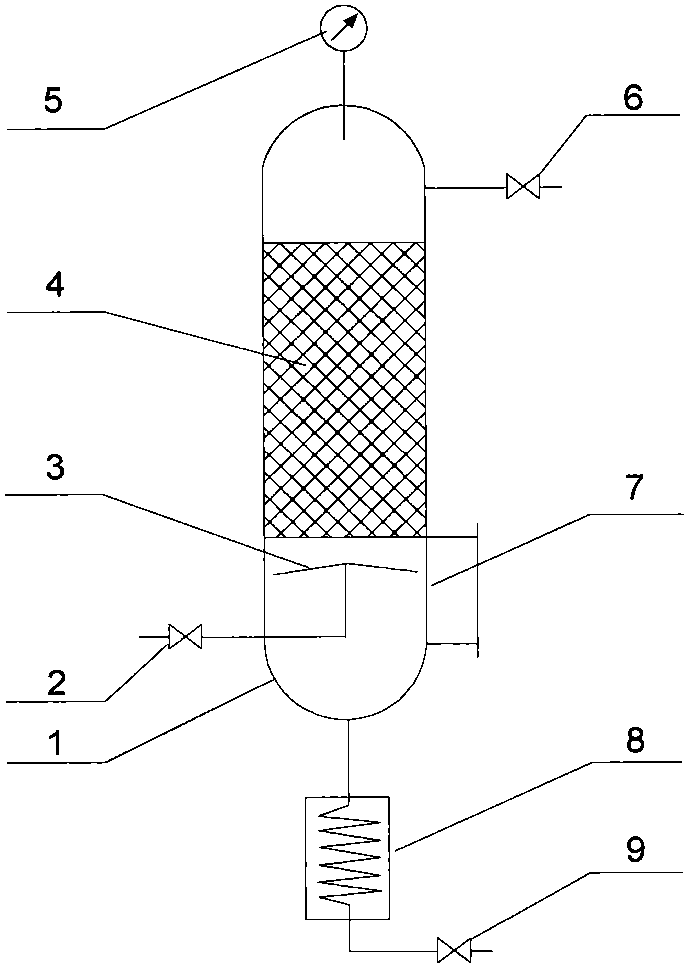

Method and apparatus for removing moisture and solid impurities in pattern material for investment casting by way of coalescence under pressure

InactiveCN102825212ADelay oxidative deteriorationProcessing speedMould handling/dressing devicesInvestment castingHigh energy

The invention discloses a method and an apparatus for removing moisture and solid impurities in pattern material for investment casting by the way of coalescence under pressure. By means of the wet coalescence effect and collision coalescence effect of surface hydrophilic coalescent pack arranged in an insulating tank on water drops, the water drops in the pattern material can be adsorbed to coalesce on the surface of the pack and gradually formed into big water drops, and the big water drops flow on the surface of the pack, come off from the edge, settle in the pattern material and separate from the pattern material; at the same time, solid impurities or soluble salt dispersed in the water drops or adsorbed on the surfaces of the water drops settle along with the water drops as well, and thereby the water and the impurities are removed from the pattern material. A control system can control heating power and regulate feed flow, discharge flow and drainage flow according to the values of a temperature sensor, a pressure sensor, a wax-water interface sensor and the like to realize continuous and stable operation. The invention overcomes the defects of conventional apparatuses, such as long treatment time, high energy consumption, low efficiency and large equipment-occupied space, and achieves an energy-saving, high-efficiency, continuous and stable pattern material water and impurity removal process.

Owner:曲险峰

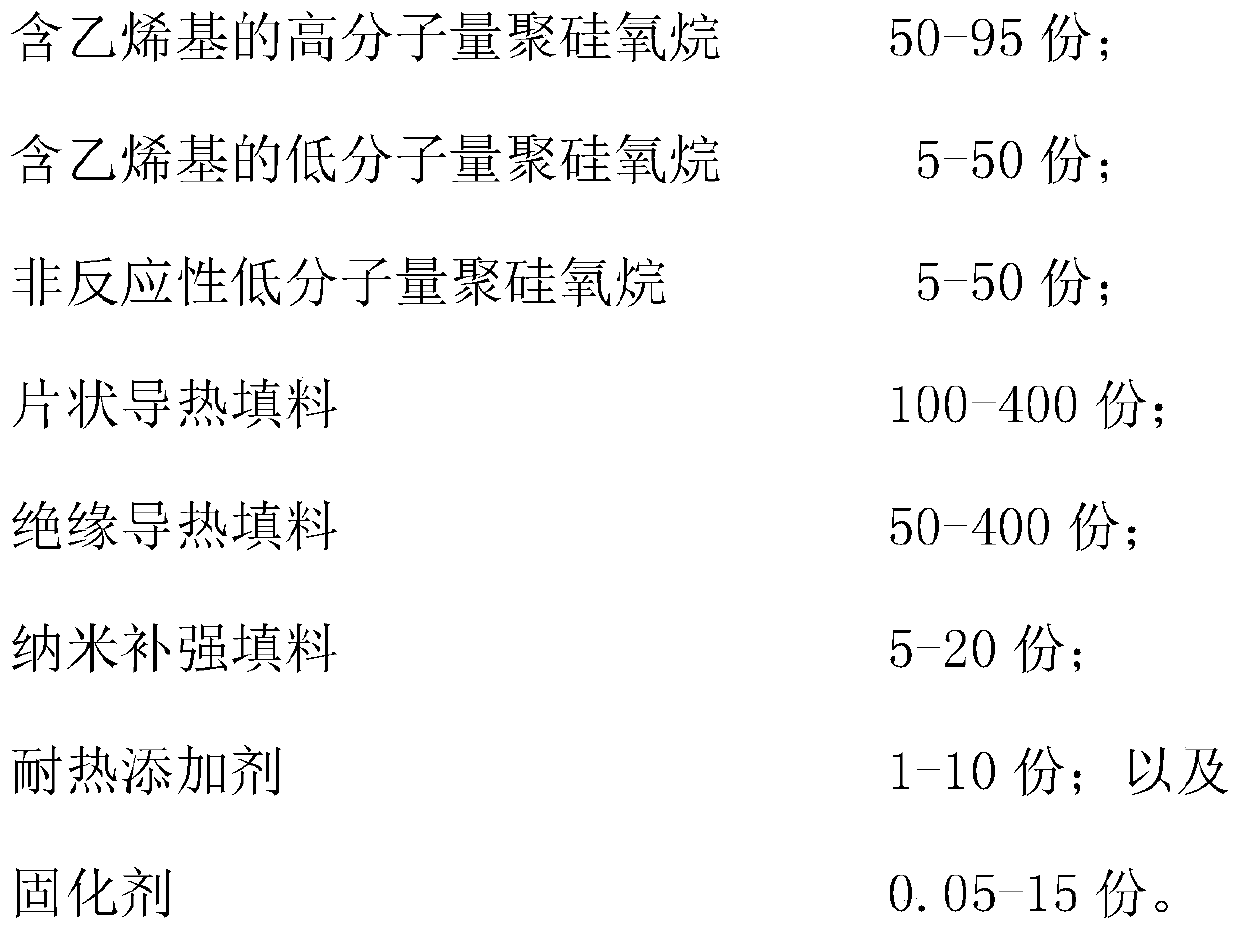

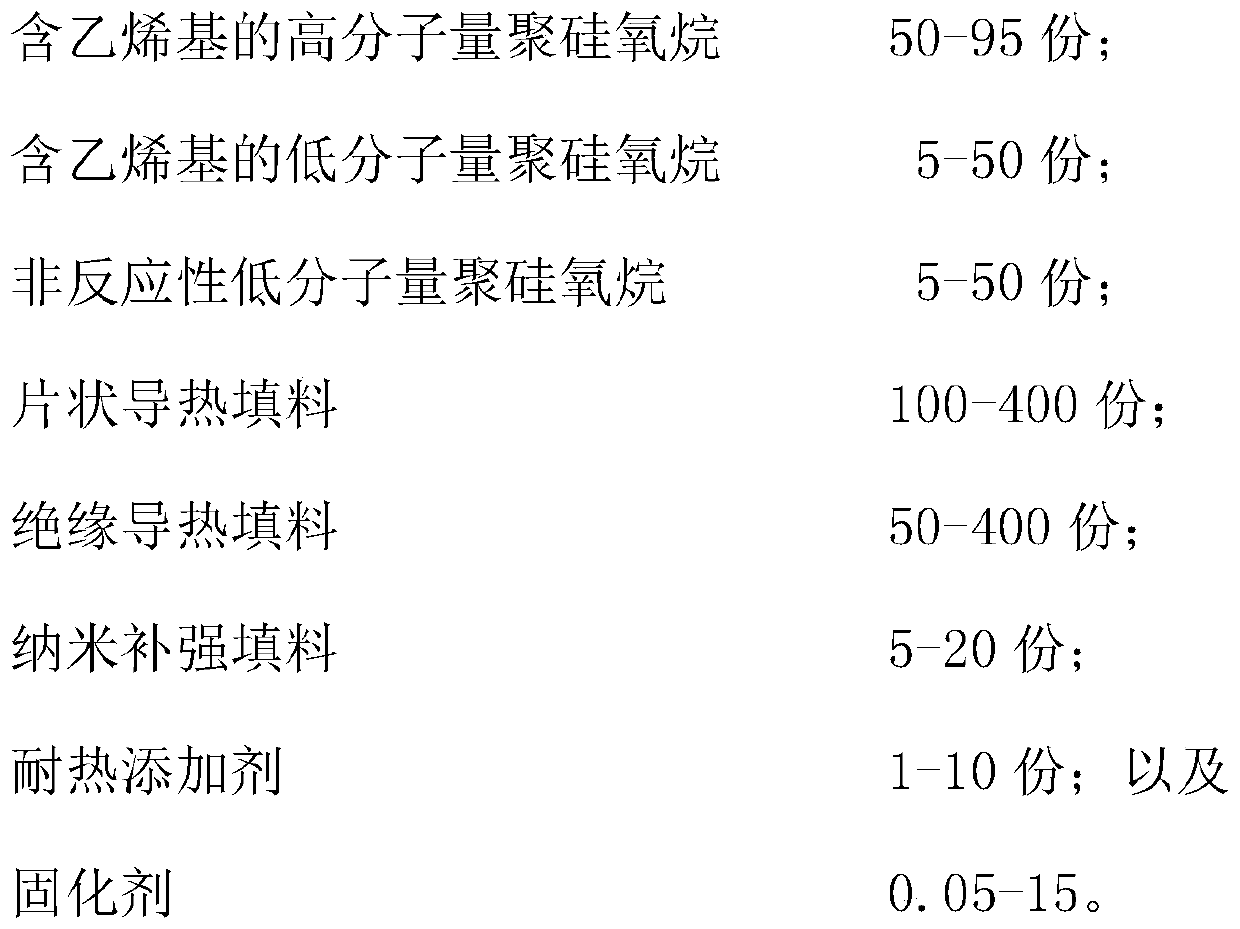

Anisotropic insulating and heat-conducting composition and preparation method thereof

InactiveCN110343389AImprove physical performanceImprove thermal conductivityHeat-exchange elementsHeat conductingElectronic component

The invention discloses an anisotropic insulating and heat-conducting composition and a preparation method thereof. The anisotropic insulating and heat-conducting composition is prepared from the following raw materials in parts by mass: 50-95 parts of vinyl-containing high-molecular-weight polysiloxane, 5-50 parts of vinyl-containing low-molecular-weight polysiloxane, 5-50 parts of non-reactive low-molecular-weight polysiloxane, 100-400 parts of sheet-like heat-conducting filler, 50-400 parts of insulating and heat-conducting filler, 5-20 parts of nano-reinforcing filler, 1-10 parts of a heatresistant additive, and 0.05-15 parts of a curing agent. The anisotropic insulating and heat-conducting composition is used for heat dissipation of electronic components such as high-power chips, theheat conductivity coefficient is improved by orienting the sheet-like heat-conducting filler, the nano-reinforcing filler is added to improve the physical properties of condensate, the heat conductivity coefficient of the heat-conducting composition is greater than 9 W / (m.K), the tensile strength is greater than 0.2 MPa, and the elongation at break is greater than 80%; and the anisotropic insulating and heat-conducting composition is prepared by an extrusion lamination process, operation is simple, and large-scale continuous production is facilitated.

Owner:SHENZHEN FRD SCI & TECH

Blank and manufacturing method and steel and manufacturing method

InactiveCN107338391AAvoid compositional segregationImprove performanceProcess efficiency improvementHigh pressureMetallurgy

Owner:PANGANG GROUP JIANGYOU CHANGCHENG SPECIAL STEEL

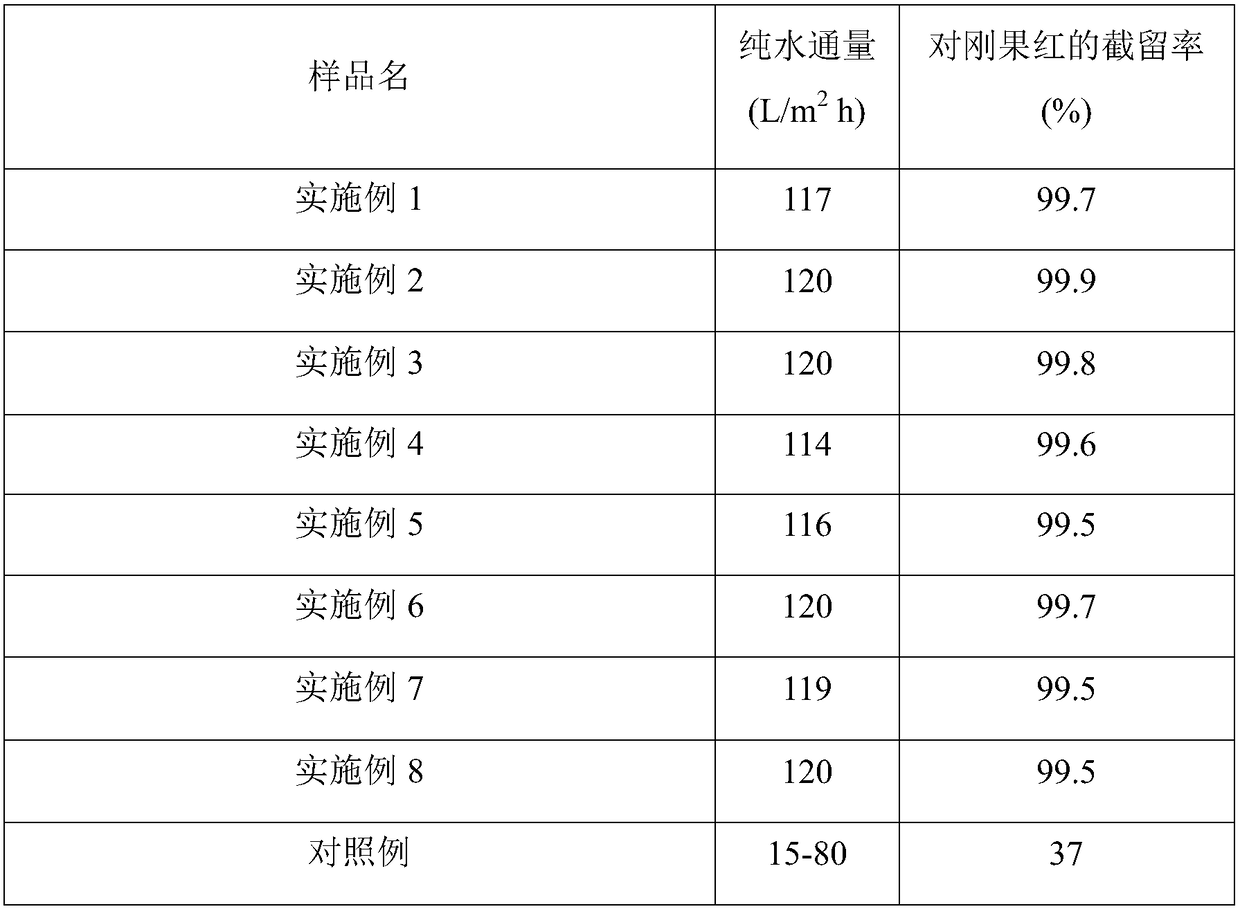

Organic-inorganic composite film and preparation method thereof

ActiveCN109012239AImprove hydrophilic abilityStrong throughputMembranesSemi-permeable membranesOrganic filmPolymer science

The invention discloses an organic-inorganic composite film and a preparation method thereof. The organic-inorganic composite membrane is prepared by the following steps: (1) preparing a film formingliquid from an organic film-forming polymer, a polar copolymer and a solvent, (2) transferring the film forming liquid into a film forming coagulation bath to obtain an organic ultrafiltration film, and (3) loading the surface and interior of the organic ultrafiltration film with inorganic particles through an alternate impregnation method to obtain the organic-inorganic composite separation film.The composite film has the characteristics of high hydrophilicity, high flux and high rejection rate of the dye. The preparation method has simple and easy processes and is suitable for continuous and stable production.

Owner:绍兴齐英膜科技有限公司

Wood wax oil preparation method

The invention discloses a wood wax oil preparation method. The wood wax oil preparation method is characterized in that lacquer tree seeds are screened and washed, and then crushing, skin-core separation, seed-skin pretreatment, solvent extraction, filtration and separation are performed so as to finally obtain the lacquer tree seed wood wax oil. The preparation method for the lacquer tree seed wood wax oil enables the preparation, the extraction and the separation of the lacquer tree seed wood wax oil to realize continuous production, improves production efficiency, a raw material utilizationrate, wood wax purity and quality and wood wax market competitiveness. The method is used, so that lacquer tree seed skin-core separating efficiency reaches 97% or above, the lacquer tree seed core perfectness ratio reaches 94% or above, and effective utilization of byproducts is facilitated.

Owner:王忠良

Edible nitraria fruit

InactiveCN106260893AConducive to large-scale continuous productionFood preparationFlavorAqueous solution

The invention relates to an edible nitraria fruit and belongs to the technical field of processing of the edible nitraria fruit. The common drynitraria fruit has uncomfortable odor and is difficult to dissolve in hot water, so that the common nitraria fruit cannot be directly used as food, solid beverage, tea substitute or component thereof. According to the invention, the dry nitraria fruit containing 10%-16% of water is fried and baked till the water content is less than 5%, and the nitraria fruit is softened and expanded after being heated, so that the expanded nitraria fruit is acquired. The expanded nitraria fruit has fragrant flavor and is easy to dissolve in hot water; the water solution of the expanded nitraria fruit is in yellow green or reddish brown; the expanded nitraria fruit can be directly used as food, solid beverage, tea substitute or component thereof; the edible nitraria fruit can be used as fresh fruit, can be applied to fruit processing and is beneficial to the large-scale continuous production.

Owner:孙多明

Bio-organic fertilizer composting tank

InactiveCN109912322AIncrease productivitySimple structureBioreactor/fermenter combinationsBiological substance pretreatmentsBiochemical engineeringOrganic fertilizer

The invention relates to a bio-organic fertilizer composting tank, which comprises a tank body, wherein a material inlet is arranged on one end of the tank body, a material outlet is arranged on the other end of the tank body, a stirring shaft is arranged in the tank body, and is provided with a stirring device and a conveying device, the stirring device is close to the material inlet, and comprises a plurality of stirring blades, the conveying device is a spiral conveying belt, one end, provided with the material inlet, of the tank body is inclined upward, and the bio-organic fertilizer composting tank further comprises a motor for driving a rotating shaft to rotate. According to the present invention, the bio-organic fertilizer composting tank is provided, has characteristics of simple structure and convenient operation, can stir and heat fertilizers, easily achieves large-scale continuous production, and can improve the production efficiency of bio-organic fertilizers and reduce labor intensity.

Owner:宜昌金旺肥业有限责任公司

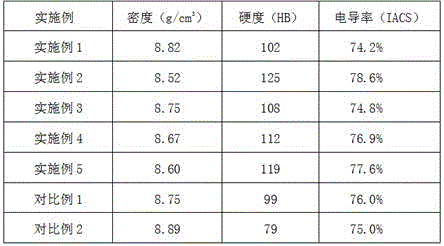

A kind of preparation method of graphene-reinforced copper-based electrical contact material

ActiveCN105695776BPrevent floatingEvenly distributedElectric switchesIntermediate frequencyRare earth

The invention relates to a preparation method for a graphene reinforced copper-matrix electrical contact material. The preparation method comprises the steps that 1.0%-5.0% by weight of graphene and 95.0%-99.0% by weight of copper powder are subjected to ball milling for powder mixing and cold press molding, copper is smelted in an intermediate frequency furnace, copper-graphene intermediate alloy is added into molten copper, a composite is prepared through a casting process, and the composite is subjected to stress relief annealing and processing molding. According to the preparation method, graphene reinforcements are added into copper alloy to be used as a framework, so that the material has high hardness, high abrasion resistance, mechanical shock resistance and fusion-welding resistance. By adding rare earth, the oxidation resistance and electric arc burning resistance of the copper-alloy electrical contact material are improved.

Owner:冷金凤

Refractory material for 3D printing and printing method thereof

InactiveCN112341217AImprove efficiencyQuality improvementAdditive manufacturing apparatusAluminateFiber

The invention discloses a refractory material for 3D printing and a printing method thereof. According to the material, the proportion of a traditional refractory casting part is improved, the material is composed of alumina aggregate, aluminate cement, silica fume, activated aluminum oxide micro-powder, additives, fibers and water in percentage by weight; and the additives comprise a solid waterreducing agent, a thickening agent and a thixotropic lubricant, and the additives improve the viscosity, fluidity and stackable property of the material and enhance the printability of the refractorymaterial. A 3D printing technology is used for producing a refractory component in the invention; convenience and rapidness are achieved, an automation degree is high, one-time integral forming of thecomponent is achieved, and large-scale continuous production is facilitated; the printed refractory component is good in compactness, the normal-temperature compression strength of the refractory component is remarkably improved, and production and manufacturing of refractory components which are complex and irregular in structure and difficult to manufacture through molds are achieved; and the whole production process is environmentally friendly, and sustainable development is facilitated.

Owner:NANJING UNIV OF SCI & TECH

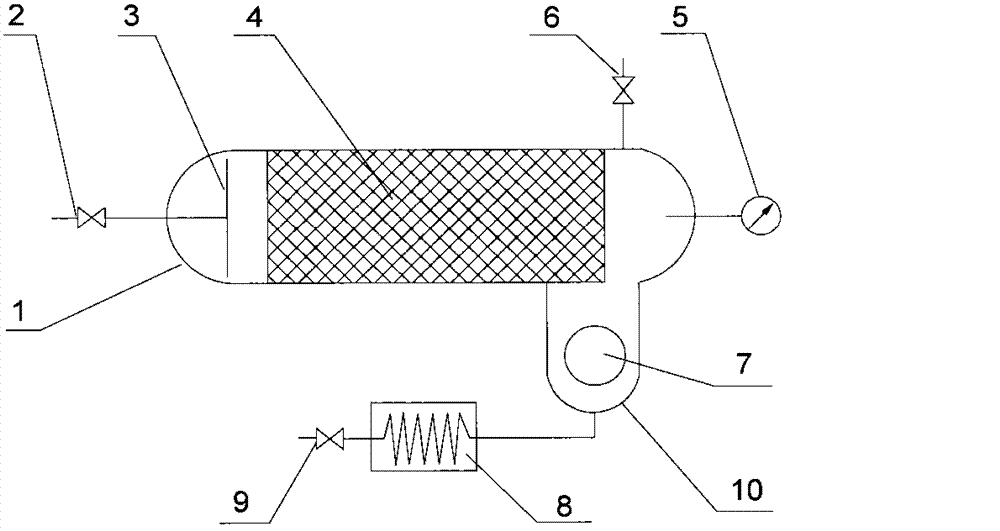

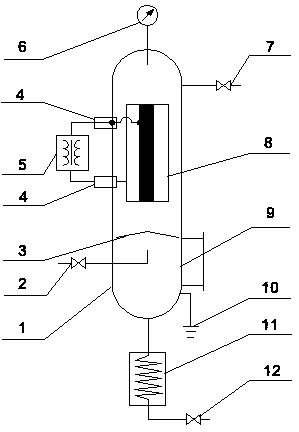

Electric dehydration and deslagging method and device for investment casting pattern materials

InactiveCN103447458AReduce the degree of oxidative deteriorationIncrease collisionMould handling/dressing devicesHigh energyHigh pressure

The invention discloses an electric dehydration and deslagging method and device for investment casting pattern materials. According to the method, an electric field force generated by a high-voltage electric field is used for performing electrophoresis coalescence, dipole coalescence, vibration coalescence and the like on water drops in the smelted pattern materials, so that the small water drops are accumulated to form water drops with great grain diameters, which are then easily deposited in and separated from the pattern materials, and meanwhile, solid impurities or soluble salts dispersed in the water drops or adsorbed to the surfaces of the water drops are deposited together with the water drops so as to realize dehydration and deslagging of the pattern materials. A control system controls heating power and regulates feeding and discharging flow and electric field parameters according to parameters including temperatures, pressures, a wax-water interface level, discharged material water content and the like of the treated pattern materials, and thus continuous and stable operation is guaranteed. According to the electric dehydration and deslagging method and device for the investment casting pattern materials, the disadvantages of long treatment time, high energy consumption, low efficiency, large occupied space and the like of a traditional device are overcome, and the energy-saving, efficient, continuous and stable dehydration and deslagging process of the pattern materials is realized.

Owner:曲险峰

Bamboo juice beverage

InactiveCN101194724BHigh nutritional valueIncrease productivityFood preparationDiabetes mellitusLiquid temperature

The invention relates to the technical field of non-alcoholic beverages, in particular to a bamboo juice beverage which uses fresh bamboo, ophiopogon root, ginseng rootlets, gynostemma pentaphylla as raw materials, and the weight ratios of main materials are bamboo 67%-81%, ophiopogon root 12%-18%, ginseng rootlets 6%-10% and gynostemma pentaphylla 1%-5%. The process comprises disintegrating clean raw material, cooking with water with 1:3-10 of weight ratio of the raw material and water with temperature between 70 DEG C-100 DEG C, dissociating in 1-2 hours with mash liquid temperature between70 DEG C- 80 DEG C, filtering the mash liquid which is dissociated, then allocating through adding sweetener and acidity conditioning agent with the ph value of bamboo between 4-5.5, then filtering again, and disinfecting filter liquor by instant high temperature, and finally obtaining the bamboo juice beverage. The bamboo juice beverage combines the nutrient compositions of bamboo, ophiopogon root, ginseng rootlets and gynostemma pentaphylla, which plays a certain health care role for human bodies, and is suitable to be used as cold drink, and is particularly suitable for patients with hypertension, hyperlipemia, and diabetes mellitus and fat people.

Owner:XIANGTAN HENGDUN GROUP SCI & TECH IND

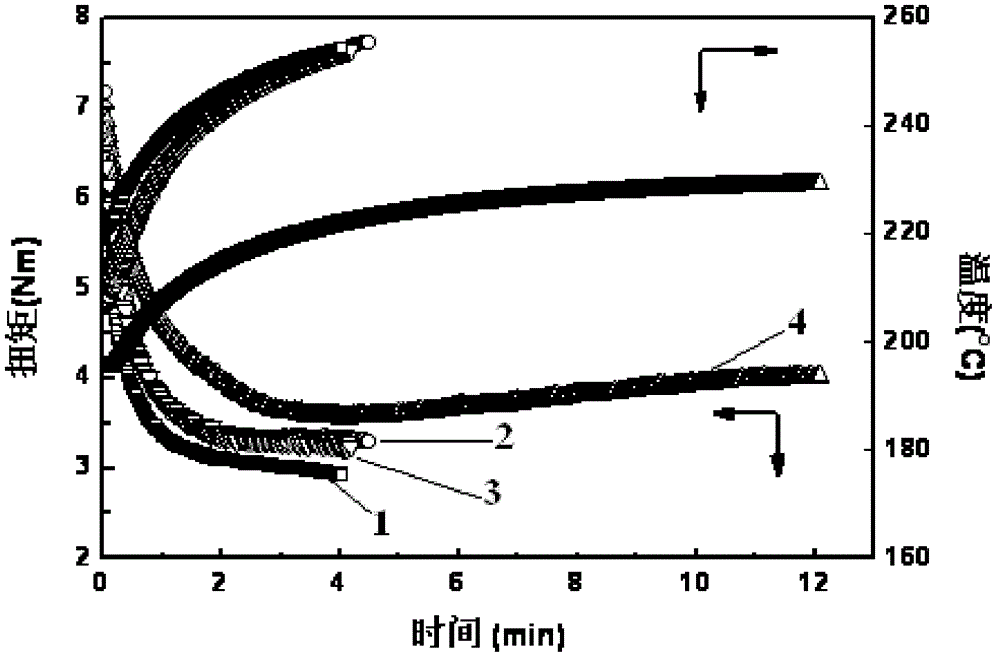

Method for preparing long-branch chain polylactic resin by combination of function group reaction and linear enantiomer polylactic acid

The invention discloses a method for preparing a long-branch chain polylactic resin by combination of a function group reaction and a linear enantiomer polylactic acid. The method comprises the following steps that a linear polylactic acid resin and a linear enantiomer polylactic acid are molten; the melt, an antioxidant and an epoxy polyfunctional monomer are mixed uniformly; and the mixture is subjected to melt blending until a reaction is finished so that the long-branch chain polylactic resin is obtained, wherein 1 to 11.1 parts of the linear enantiomer polylactic acid and 0.1 to 1 part of the epoxy polyfunctional monomer are used. Through utilization of a function group reaction having a high reaction rate at a high temperature, under the condition of a small amount of the linear enantiomer polylactic acid, the long-branch chain polylactic resin as a polylactic acid material of which melt strength is improved obviously is obtained. The long-branch chain polylactic resin has good foaming film-blowing molding effects. Through adjustment of a use amount of the epoxy polyfunctional monomer, the content of the linear enantiomer polylactic acid and reaction conditions, the method realizes branching degree control to a certain degree.

Owner:CHINA PETROLEUM & CHEM CORP +1

A modified resin, raw material composition, preparation method, foaming material and application

The invention discloses a modified resin, raw material composition, preparation method, foaming material and application. The raw material composition includes resin and epoxy polyfunctional monomer, the weight ratio of the resin and the epoxy polyfunctional monomer is 100:(0.5-5), and the resin is that the active group is located at the chain end based linear resin. The present invention can conveniently and efficiently modify the resin whose active group is located at the end of the chain through the reaction of the functional group. The prepared modified resin has high melt strength and can achieve good foaming, film blowing and other processing and molding. Effect.

Owner:EAST CHINA UNIV OF SCI & TECH

A method for strengthening the separation of by-product ammonium chloride in the production of potassium nitrate by metathesis

InactiveCN105084396BEasy to separateAvoid consumptionChemical industryAlkali metal nitrate preparationFatty amineAmmonium nitrate

The invention discloses a method for strengtheningly separating byproduct ammonium chloride from potassium nitrate produced through a complex decomposition method. According to the method, on the basis of a technology for producing the potassium nitrate through a traditional complex decomposition method, agents such as higher straight-chain fatty amine with the number of C ranging from 12 to 20 for flotation is added in a reaction system, and under the condition of a certain pH value, after reaction and crystallization are conducted, under the stirring action or the pumping action of a pump, effective separation of the byproduct ammonium chloride and the potassium nitrate is completed through the mode of carrying the ammonium chloride through foam. Compared with the technologies such as washing and heat dissolving in traditional production, the method has the advantages of being easy and convenient to operate, small in agent dosage, good in separation effect and the like. On one hand, the grade of crude potassium nitrate is promoted, and the content of impurities such as NH4<+> and Cl<-> is significantly decreased; on the other hand, the effects of saving energy and reducing consumption are significant, and the consumption of water in the washing process is reduced. The method is applied to large-scale continuous production of the potassium nitrate through the potassium chloride and ammonium nitrate complex decomposition method, and the economic benefits and the social benefits are obvious.

Owner:XIANGTAN UNIV

Method of continuously preparing 1,2-dihydroxypropane by glycerin catalytic hydrogenation

The invention discloses a making method of 1, 2-propanediol under mild condition, which is characterized by the following: adopting copper, zinc and manganese and or aluminium catalyst; aerating glycerin and hydrogen continuously from the top of reactor; hydrogenating glycerin at 200-250 deg.c under 2.5-5Mpa; outputting and collecting reacting product from the bottom of reactor continuously; separating gas; returning to recycle; setting the weight rate of metal element of catalyst at 16-48:24-48:0.15-4:0-8.

Owner:NANJING TECH UNIV

Preparation method of konjac fermented soybean milk powder

ActiveCN111758788ALow drying temperatureDry fastMilk preservationOther dairy technologyBiotechnologyLactic acid bacterium

The invention discloses a preparation method of konjac fermented soybean milk powder. The preparation method comprises the following steps: firstly, preparing enzymolysis konjac liquid and soybean milk separately, then adding the enzymolysis konjac liquid into the soybean milk, adding soybean protein isolate, then performing mixed fermentation through various lactic acid bacteria, and finally performing low-temperature spray drying, thereby obtaining the konjac fermented soybean milk powder. By adding the soy isolate protein and the konjac enzymatic hydrolysate and then fermenting with the mixed lactic acid bacteria, the soy milk can have a good health-care effect, and the product is high in protein content, rich in nutrition, unique in flavor and good in palatability; and low-temperaturespray drying is adopted, the viable count of lactic acid bacteria in fermented soybean milk powder can be preserved to the maximum extent, and the prepared powdery product has the advantages of beinghigh in lactic acid bacteria activity, small in storage space, convenient to eat and the like.

Owner:南昌泰康食品科技有限公司

A kind of method of producing high-quality potassium nitrate by potassium chloride and ammonium nitrate metathesis cycle method

ActiveCN105060317BHigh quality contentSimple separation processAlkali metal nitrate preparationWater useSeparation technology

The invention discloses a potassium chloride and ammonium nitrate double decomposition and circulation method for producing high quality potassium nitrate. According to the method, potassium chloride and ammonium nitrate are taken as the raw materials, and the method comprises steps of raw material preparation, potassium nitrate crystallization, foam floatation and separation, potassium nitrate refinement, and ammonium chloride crystallization. The method is developed on the basis of conventional potassium nitrate production technology by improving part of the technology; wherein in the foam flotation and separation technology, in the presence of a floatation reagent (C12-C20 higher straight-chain aliphatic amine) and in a certain pH value range, the ammonium chloride and coarse potassium nitrate can be separated through foam entrainment; in the potassium nitrate refinement, the refined potassium mother liquid in the previous circulation is used to wash the coarse potassium nitrate, and then potassium nitrate is purified by sodium carbonate. In one aspect, the conventional potassium nitrate production technology is optimized, the potassium nitrate quality is improved, and the impurity content of the potassium nitrate product is greatly reduced. In the other aspect, the water using amount is reduced, the labor intensity is also reduced, and the production cost is saved. The industrial grade KNO3 mass content is not less than 99.7%, the content of Cl<-> is not more than 0.01%, and the content of NH4<+> is not more than 0.03%. the method has a wide application value and can generate prominent social benefit and economic benefit.

Owner:湖南丹化农资有限公司

Method for preparing long-chain branch polylactic acid resin by combination of two-step function group reaction and linear enantiomer polylactic acid

ActiveCN102977354BImprove melt strengthIncreased degree of long branchingFunctional monomerReaction rate

The invention discloses a method for preparing a long-chain branch polylactic acid resin by combination of a two-step function group reaction and a linear enantiomer polylactic acid. The method comprises the following steps of carrying out melting of a linear polylactic acid resin and a linear enantiomer polylactic acid, adding an anti-oxidant, an anhydride polyfunctional monomer and an epoxy polyfunctional monomer into the melted linear polylactic acid resin and the linear enantiomer polylactic acid, uniformly mixing, and carrying out melt blending until a reaction is finished to obtain the long-chain branch polylactic acid resin. The method has the advantages that a polylactic acid material having obviously improved melt strength is obtained by a two-step function group reaction having a fast high-temperature reaction rate in the presence of a less amount of a linear enantiomer polylactic acid so that good foaming film-blowing processing molding effects are obtained; and through adjustment of use ratios of two functional monomers and adjustment of linear enantiomer polylactic acid content and reaction conditions, a branching degree is controlled to a certain degree.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing long-branch chain polylactic resin by combination of function group reaction and linear enantiomer polylactic acid

The invention discloses a method for preparing a long-branch chain polylactic resin by combination of a function group reaction and a linear enantiomer polylactic acid. The method comprises the following steps that a linear polylactic acid resin and a linear enantiomer polylactic acid are molten; the melt, an antioxidant and an epoxy polyfunctional monomer are mixed uniformly; and the mixture is subjected to melt blending until a reaction is finished so that the long-branch chain polylactic resin is obtained, wherein 1 to 11.1 parts of the linear enantiomer polylactic acid and 0.1 to 1 part of the epoxy polyfunctional monomer are used. Through utilization of a function group reaction having a high reaction rate at a high temperature, under the condition of a small amount of the linear enantiomer polylactic acid, the long-branch chain polylactic resin as a polylactic acid material of which melt strength is improved obviously is obtained. The long-branch chain polylactic resin has good foaming film-blowing molding effects. Through adjustment of a use amount of the epoxy polyfunctional monomer, the content of the linear enantiomer polylactic acid and reaction conditions, the method realizes branching degree control to a certain degree.

Owner:CHINA PETROLEUM & CHEM CORP +1

Trichoderma spore powder as well as preparation method and application thereof

InactiveCN102067885BInhibitionTo achieve the effect of preventionBiocideFungicidesMicroorganismSpore

The invention discloses a trichoderma spore powder as well as a preparation method and application thereof. The trichoderma spore powder contains trichoderma spore powder and a drying aid, wherein the trichoderma spore powder is the spore powder of Trichoderma sperellum T1 which is preserved in the general microorganism center of CCCCM (China Committee for Culture Collection of Microorganisms) and has the preservation number of CGMCC NO: 3531 and a rDNA ITS region segment sequence shown in SEQ ID NO:1; the drying aid is one or more of beta-cyclodextrin, potato starch and soluble starch. The trichoderma spore powder has an effective prevention and control effect on banana vasicular wilt, and has a remarkable antagonism effect on various pathogenic funguses, especially on soil-borne funguses. The preparation time is saved with the preparation method of the trichoderma spore powder, which can be used for preparing the trichoderma spore powder which has high density, high germination rate and high drying efficiency and is easy to store, transport and use.

Owner:惠州市南天生物科技有限公司 +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com