Electric dehydration and deslagging method and device for investment casting pattern materials

An investment casting and electric dehydration technology, which is applied in the cleaning/processing machinery of casting mold materials, casting molding equipment, manufacturing tools, etc., can solve the problems of high energy consumption, low processing efficiency, and deterioration of mold material performance, and achieve The effect of low energy consumption, improving the quality of the mold material and weakening the strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

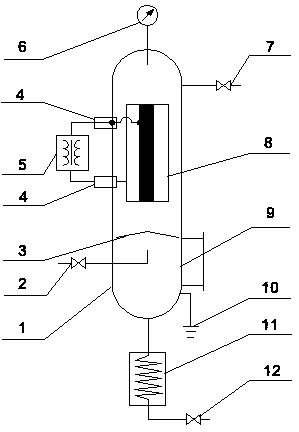

[0032] Such as figure 1 As shown, the present investment casting mold material electric dehydration deslagging vertical tank device includes a heat preservation tank 1, a high-voltage power supply system 5, and a control system. The outer wall of the heat preservation tank 1 is grounded 10, and a combined electrode 8 is provided with a high-voltage introduction device 4 Connected to the high-voltage power supply system 5, the inlet distributor 3 is located below the combined electrode 8; the top of the insulation tank 1 is connected with the discharge control valve 7 and is provided with a pressure sensor 6; the bottom of the insulation tank 1 is connected with the separation water cooler 11 Connected, the outlet of the separated water cooler 11 is provided with a drainage control valve 12; an observation window 9 is provided at the wax water interface under the heat preservation tank 1, and the wax water interface level sensor can be placed at the window 9; the control system an...

Embodiment 2

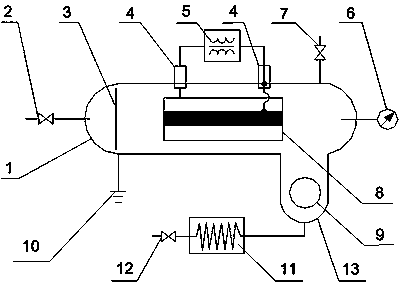

[0038] Such as figure 2 As shown, the investment casting mold material electric dehydration slag removal horizontal tank device includes a heat preservation tank 1, a high-voltage power supply system 5, and a control system. One end of the heat preservation tank 1 is connected to the feed control valve 2, and the other end is connected to the outlet from the top. The material control valve 7 is connected; the inlet distributor 3 is provided behind the inlet in the thermal insulation tank 1; the outer wall of the thermal insulation tank 1 is grounded 10, and the combined electrode 8 is provided with the high-voltage power supply system 5 through the high-voltage introduction device 4, and A pressure sensor 6 is provided; the bottom of the heat preservation tank 1 is provided with a water bag 13, which is connected to the separated water cooler 11, and the outlet of the separated water cooler 11 is provided with a drainage control valve 12; Window 9, wax water interface level sen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com