Method for preparing long-branch chain polylactic resin by combination of function group reaction and linear enantiomer polylactic acid

A technology of long-chain branched polylactic acid and polylactic acid resin is applied in the field of preparing long-chain branched polylactic acid resin by combining functional group reaction with linear enantiomer polylactic acid, which can solve the problems of low production efficiency of long-chain branched polylactic acid, etc. Significant branching effect, low melt index, long branching degree improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

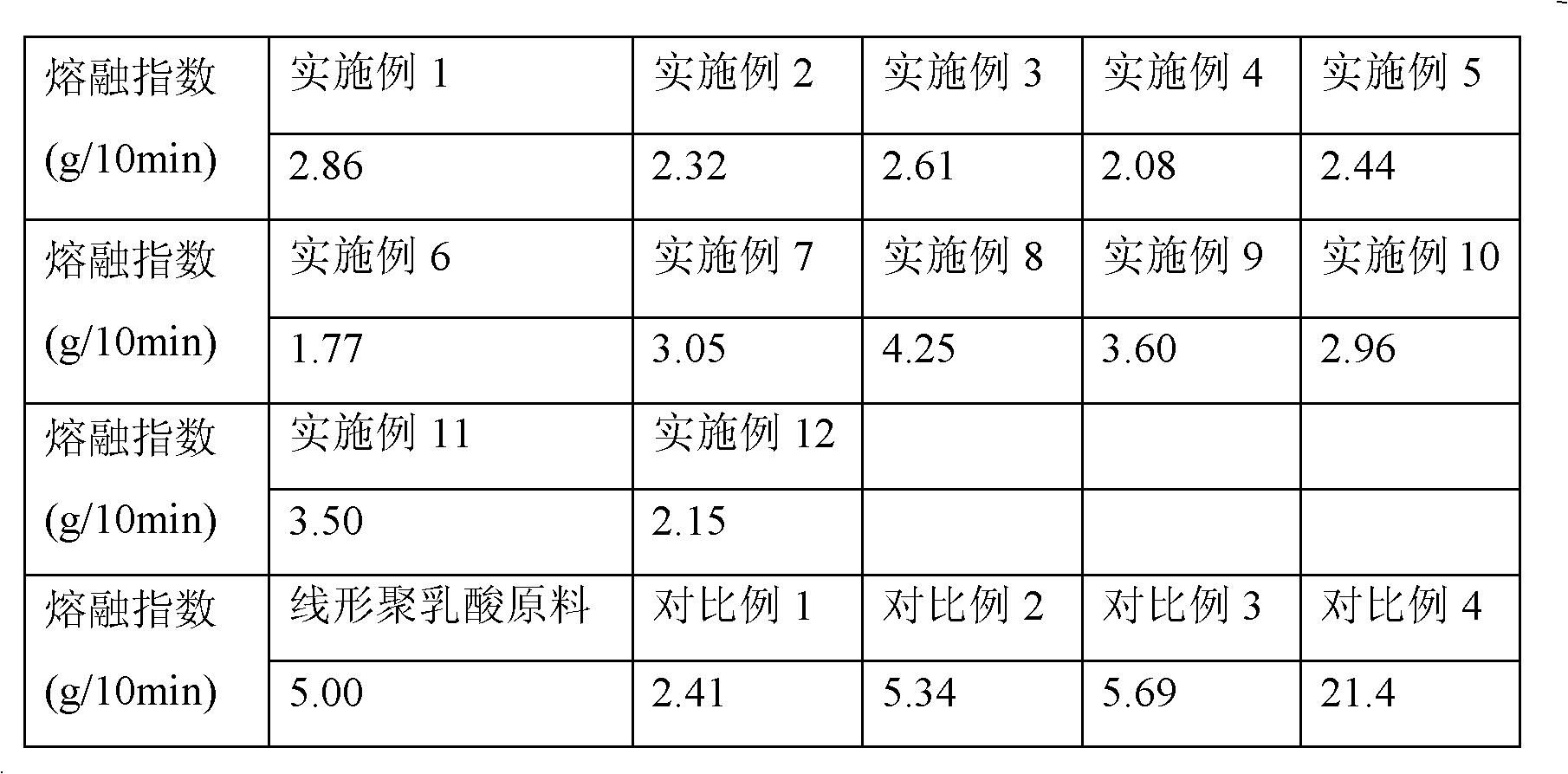

[0024]100 parts by weight of linear polylactic acid resin and 5.3 parts of linear enantiomeric polylactic acid were added to an internal mixer with a rotation speed of 20 rpm at 250°C, After being melted at a constant temperature, add 0.16 parts of 1,3,5-trimethyl-2,4,6-tris(3,5-di-tert-butyl-4-hydroxybenzyl)benzene, 0.34 parts of N, N,N',N'-tetraglycidyl-4,4'diaminodiphenylmethane, mixed for 2 minutes; then the mixer was raised to 100 rpm, melt-blended until the end of the reaction, that is, stopped after about 3.5 minutes , long-chain branched polylactic acid was obtained. The results of the melt index (190° C., 2.16 kg load) of the obtained reaction product material measured according to ASTMD1238 are shown in Table 1.

Embodiment 2

[0026] Long-chain branched polylactic acid prepared by functional group reaction combined with linear enantiomer polylactic acid

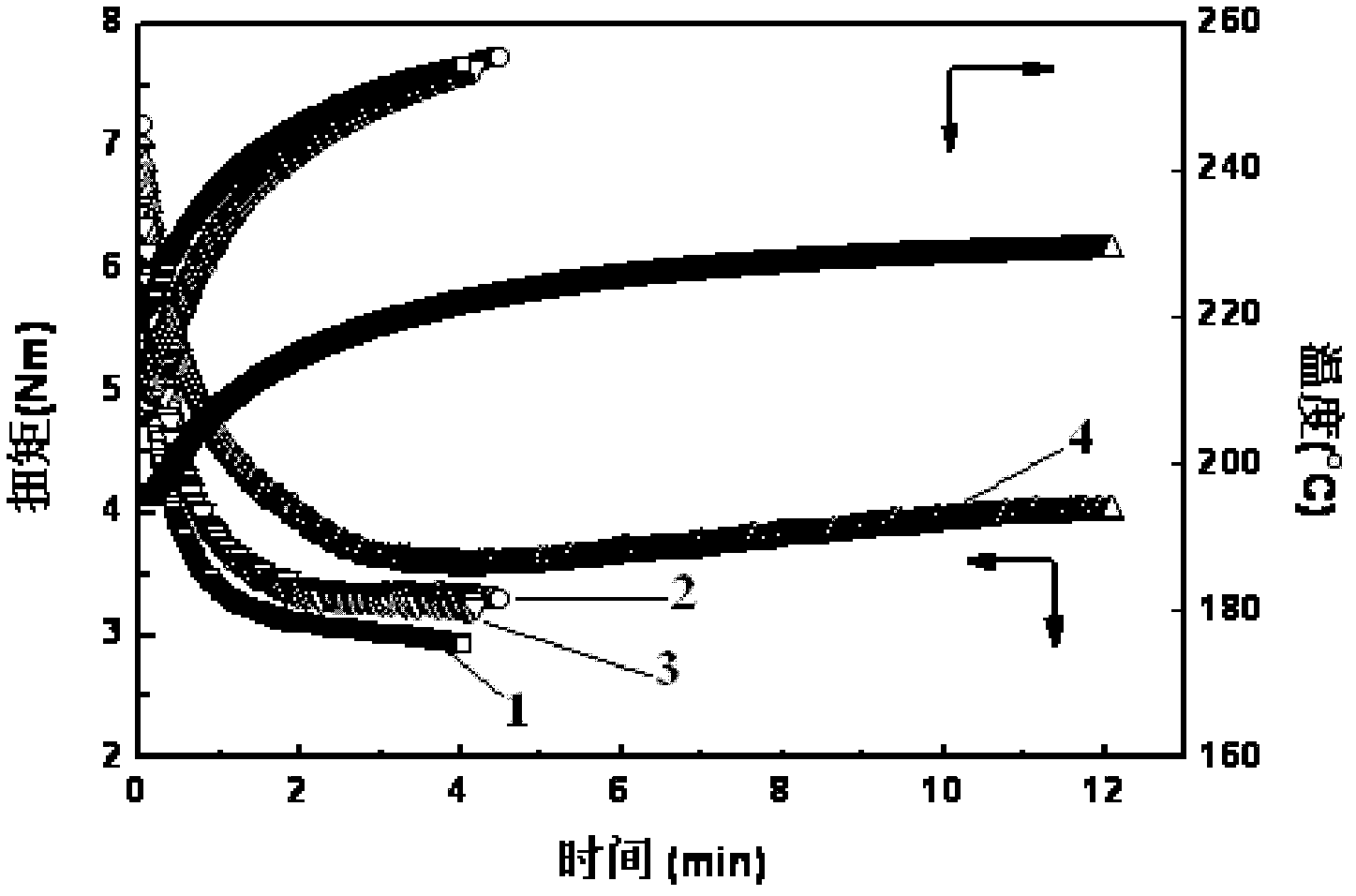

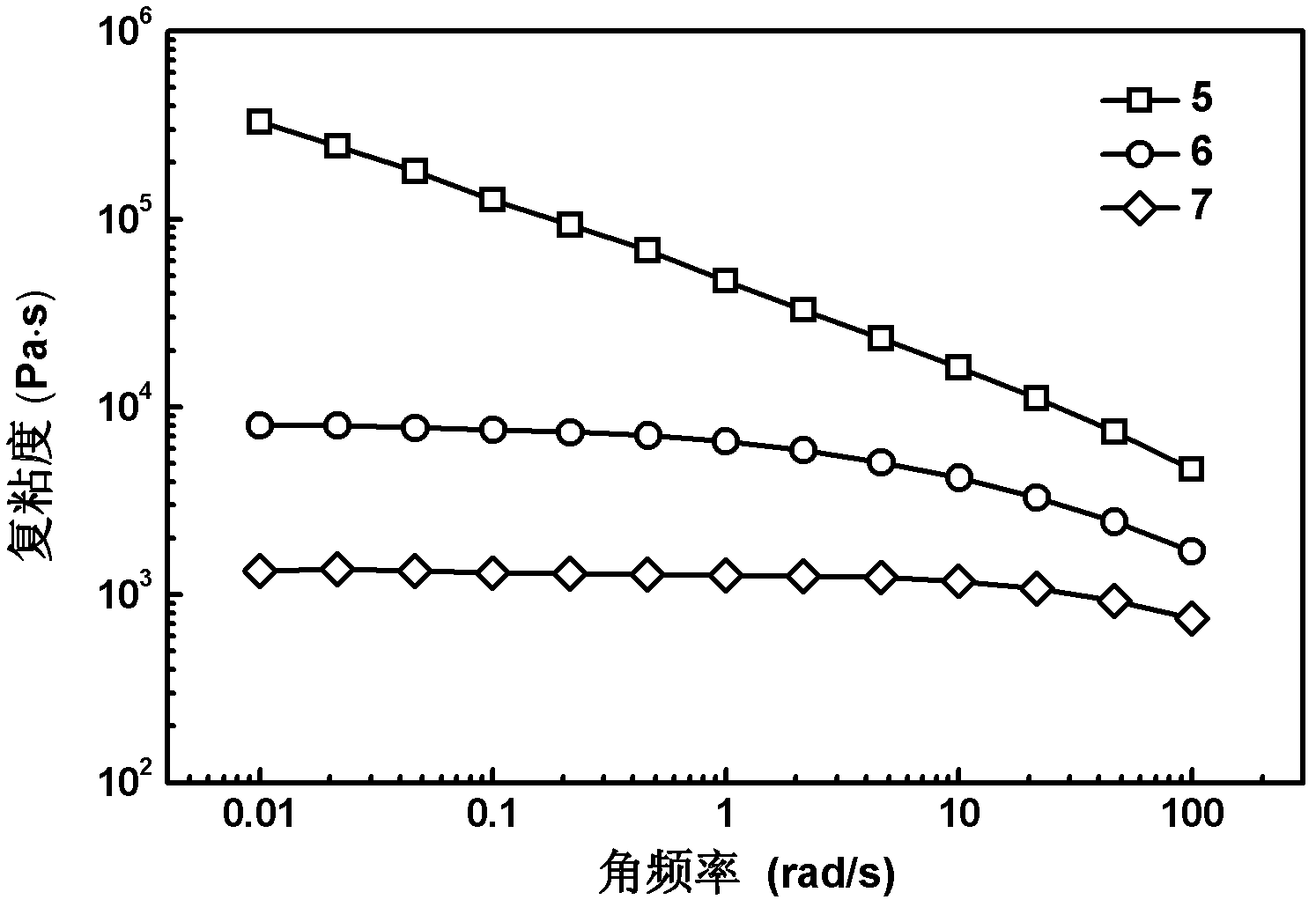

[0027] 100 parts by weight of linear polylactic acid resin and 11.1 parts of linear enantiomeric polylactic acid were added to an internal mixer with a rotating speed of 20 rpm at 250 ° C, and 0.17 parts of 1,3,5-trimethyl were added successively after they were melted at a constant temperature. -2,4,6-Tris(3,5-di-tert-butyl-4-hydroxybenzyl)benzene, 0.36 parts of N,N,N',N'-tetraglycidyl-4,4'di Aminodiphenylmethane, mixed for 2 minutes; then the internal mixer was raised to 100 rpm, and the mixture was blended until the reaction ended, and stopped after about 3.5 minutes to obtain long-chain branched polylactic acid. The melt index test results are shown in Table 1. See the torque and temperature curves in the mixer figure 1 , at 180°C and strain of 5%, the viscosity versus frequency curve is shown in figure 2 .

Embodiment 3

[0029] Long-chain branched polylactic acid prepared by functional group reaction combined with linear enantiomer polylactic acid

[0030] 100 parts by weight of linear polylactic acid resin and 5.3 parts of linear enantiomeric polylactic acid were added at 250° C. to an internal mixer with a rotating speed of 20 rpm, and 0.16 parts of 1,3,5-trimethyl were added in sequence after they were melted at a constant temperature. -2,4,6-Tris(3,5-di-tert-butyl-4-hydroxybenzyl)benzene, 0.55 parts of N,N,N',N'-tetraglycidyl-4,4'di Aminodiphenylmethane, mixed for 2 minutes; then the internal mixer was raised to 100 rpm, and the mixture was blended until the reaction ended, and stopped after about 3.5 minutes to obtain long-chain branched polylactic acid. The melt index test results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com